Shear Stress Calculator

At Fluigent, we understand the critical role shear stress plays in microfluidics research. Hence, we introduce our Shear Stress Calculator, a tool designed to simplify your tasks as researchers, scientists, and engineers in the field.

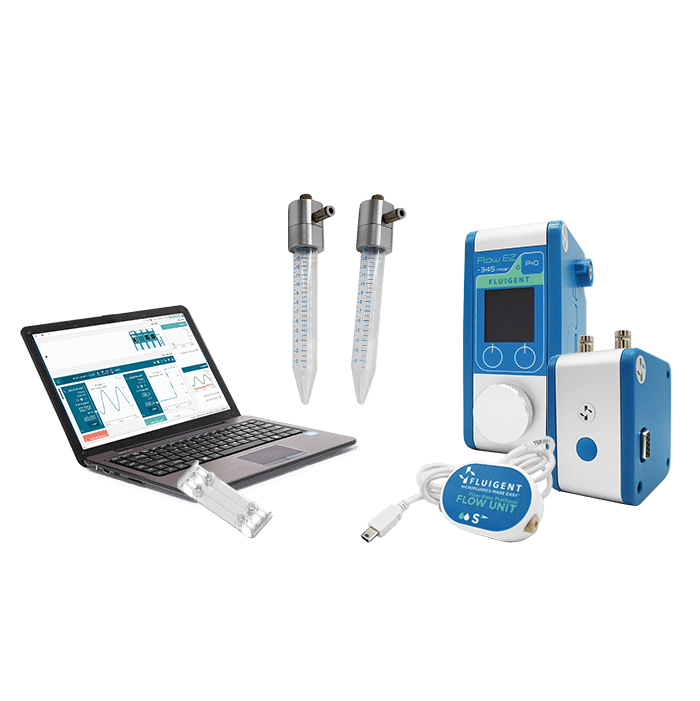

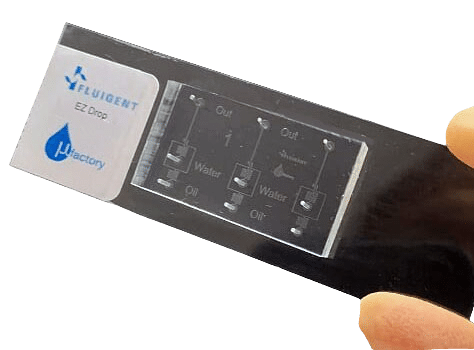

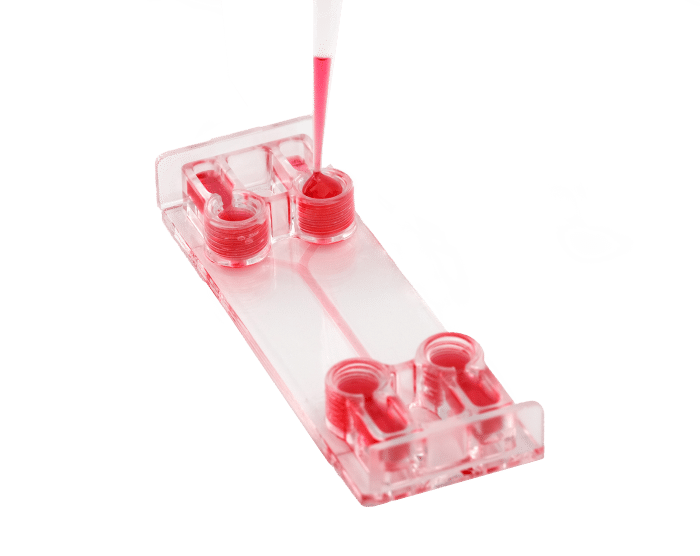

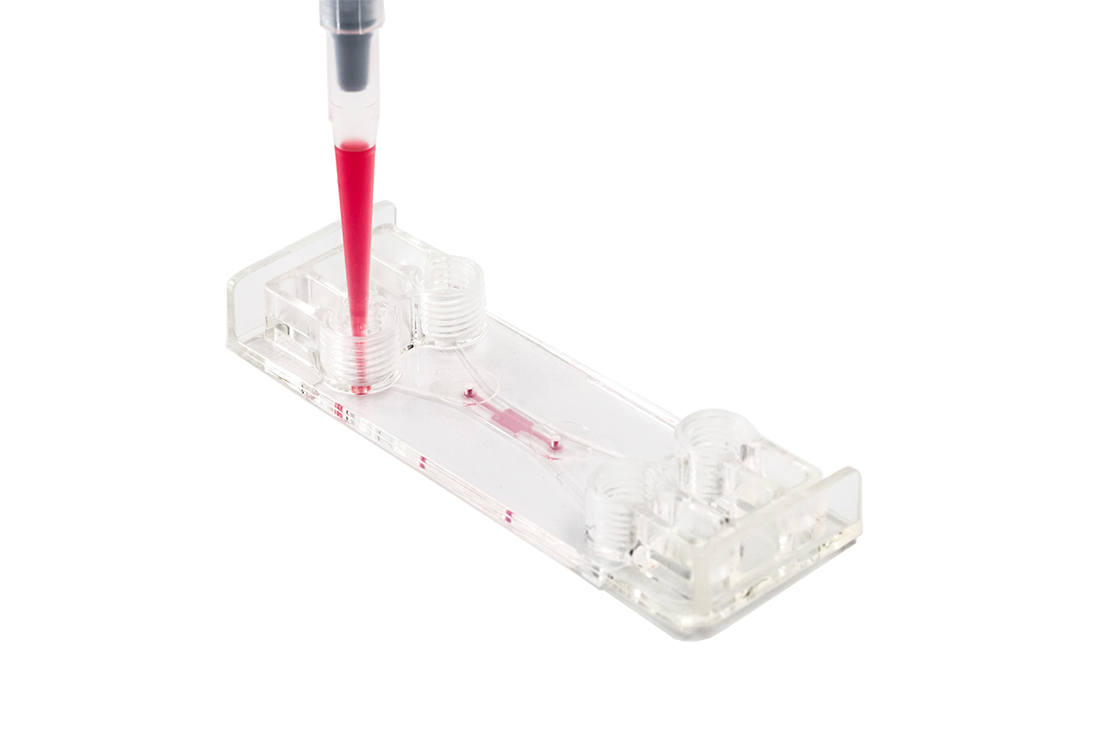

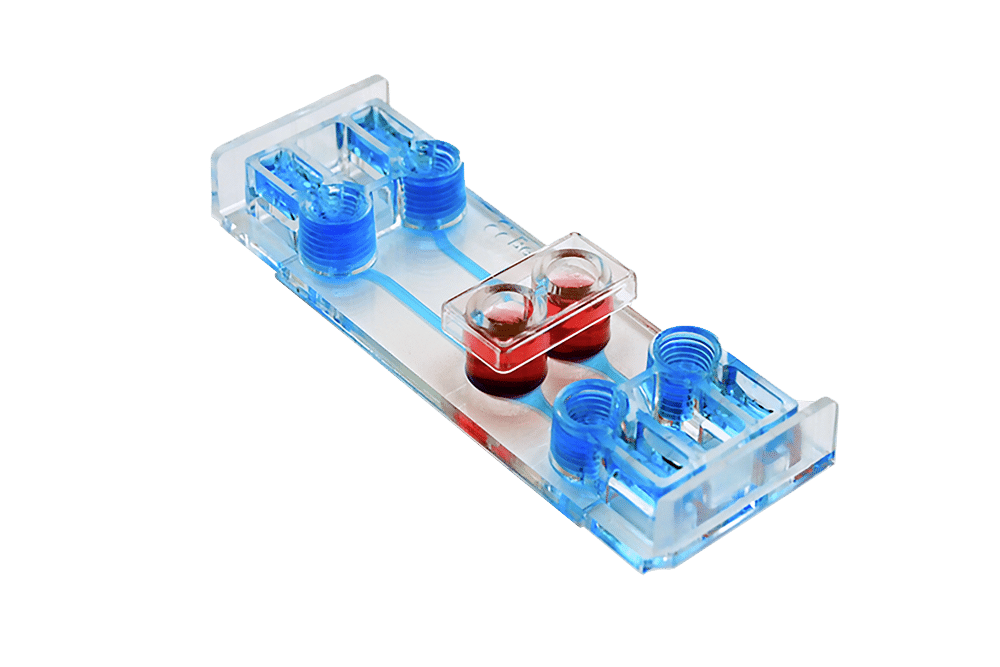

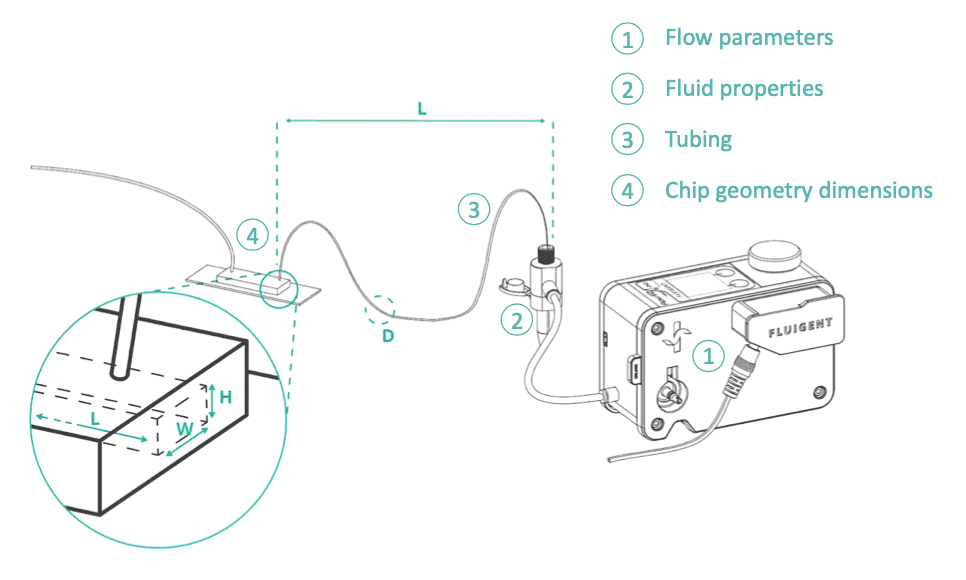

You can use our Shear Stress Calculator to determine your experimental parameters. Define the flow rate or the pressure to be applied in your system, the dimension of microfluidic chip and tubing length in order to apply the correct shear stress for your cell culture under flow conditions.

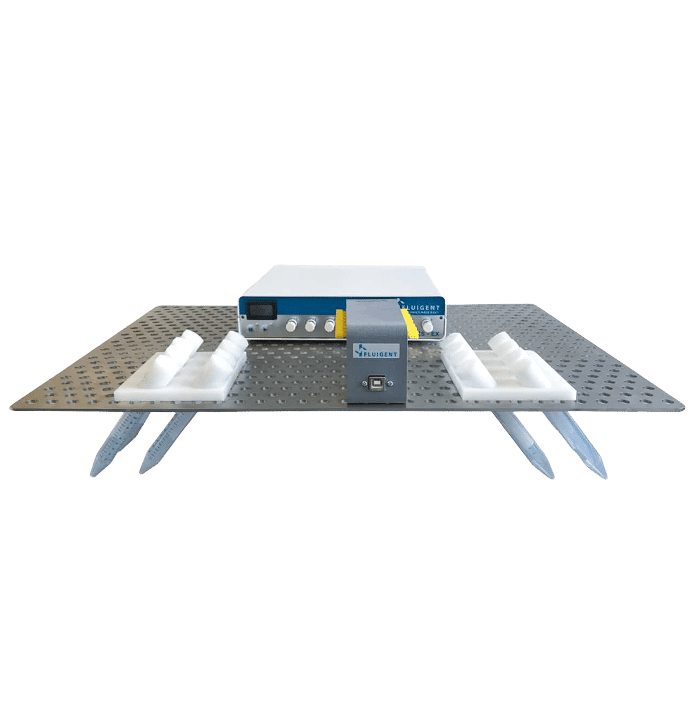

Of note, the dimension of your chip (width) as well as the tubing connected to it (inner diameters and length) determine the overall hydraulic resistance of your system.

Set your parameters and calculate

What is shear stress?

Shear stress is the dragging force created by fluid friction on a surface in motion. Cells exposed to fluid flow experience this stress, influencing their phenotype, morphology, and maturation.

Optimize Your Experiments with Shear Stress Calculator

Use our Shear Stress Calculator to precisely determine your experimental parameters. Input flow rate, pressure, microfluidic chip dimensions, and tubing length to apply the ideal shear stress for your cell culture under flow conditions.

Considerations for Hydraulic Resistance

The dimensions of your chip (width) and connected tubing (inner diameters and length) collectively determine the overall hydraulic resistance. These factors are crucial in achieving accurate shear stress in your system.

Why Shear Stress Calculation Matters

Accurate shear stress calculation is vital for designing experiments that replicate physiological conditions and yield dependable results. Our Shear Stress Calculator streamlines this process, offering a user-friendly interface for determining shear stress values in microfluidic systems.

Easy Experiment Optimization

Designed with simplicity in mind, our shear stress calculator accommodates both beginners and experts. Its intuitive interface allows researchers to confidently input parameters, ensuring accurate shear stress values for successful experiments.

Tutorial video

Our Shear Stress Calculator helps determine experimental parameters, by predicting the shear stress level induced by a set-up and an application.

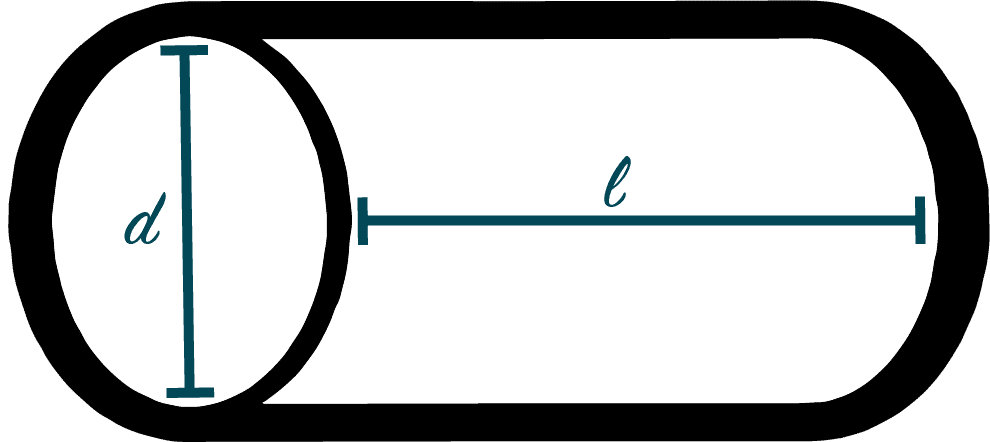

Cylindrical channel

For a circular cross-section of diameter d

Shear stress is:

τ = 4ηQ / r³π

Where Q is the flow rate, η the dynamic viscosity and r the radial distance from the centerline of the channel (r=d/2)

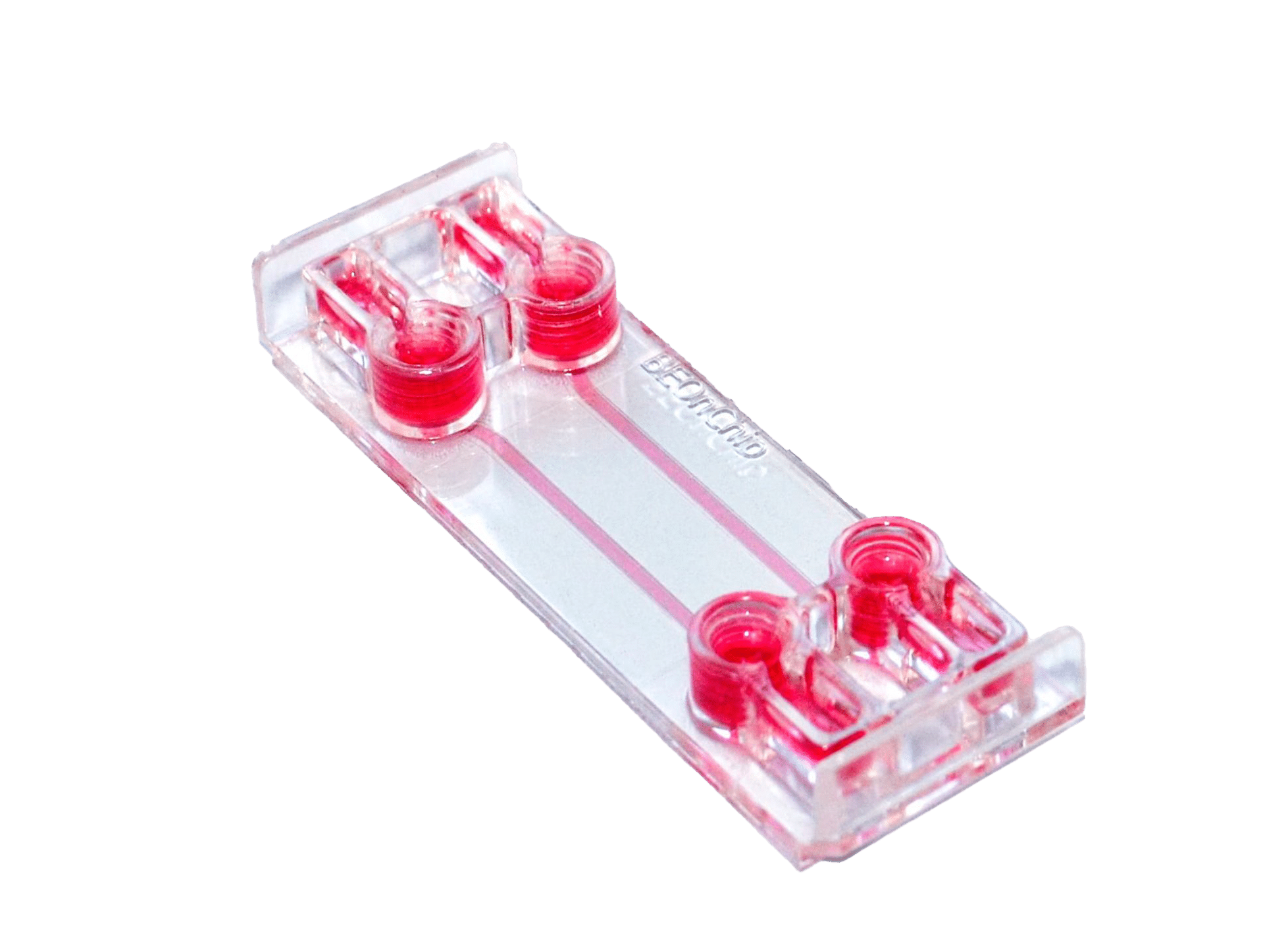

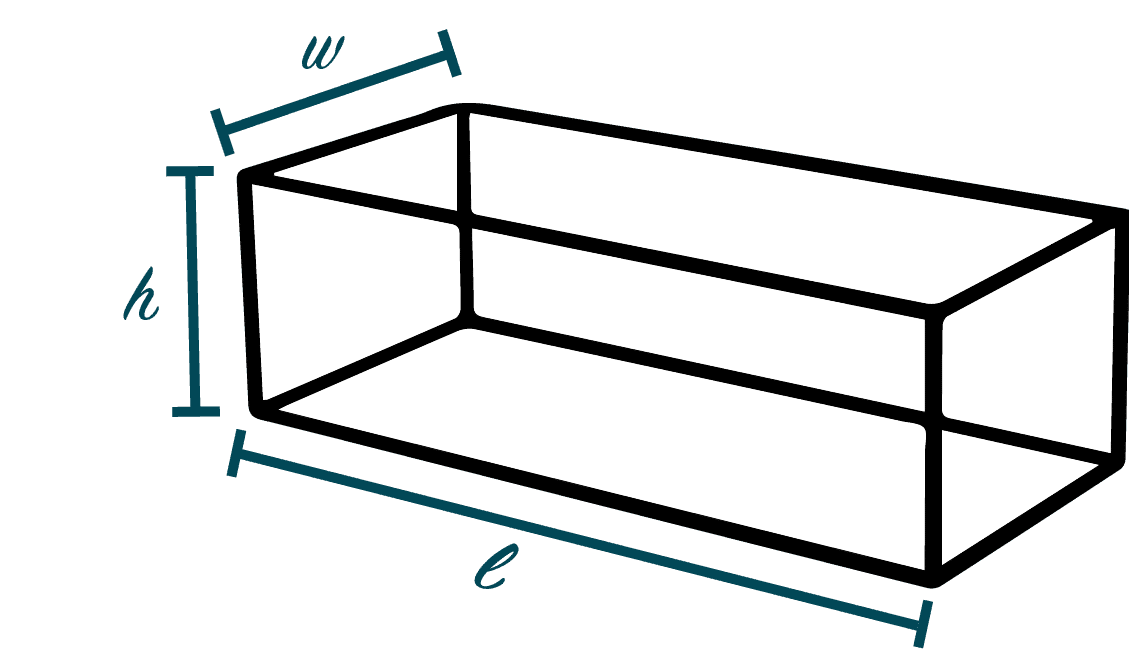

Rectangular channel

In rectangular channels, the flow velocity profile and subsequent shear stress are more complex. Wall shear stress is not constant and varies across the top, bottom, and side walls of the channel. However, the geometry can be simplified by considering two infinite parallel plates instead of closed channels.

Under this assumption, the shear stress follows the equation:

τ = 6ηQ / h²w

Where Q is the flow rate, η the dynamic viscosity, h the channel height and w the channel width

In order to determine the shear stress applied onto your cells cultured under flow, please indicate the following values:

- Flow parameters (flow rate, pressure or shear stress)

- Fluid properties (viscosity and density)

- Tubing dimensions (optional) – important to calculate the hydraulic resistance of your system

- Channel geometry and dimensions inside your microfluidic chip – important for both the hydraulic resistance and the shear stress

Why use our shear stress calculator

- To extract the value of the shear stress applied in your system when working with a fixed flow rate or a fixed pressure

- To determine which flow rate or pressure to apply in order to deliver a specific shear stress