Mastering Microfluidic Chips: An In-Depth Definition

Microfluidic chips, also known as a lab-on-a-chip or biochips, are small-scale devices used across diverse scientific studies and industrial fields. They allow precise control, manipulation, and analysis of tiny volumes of fluids.

Microfluidic chip definition

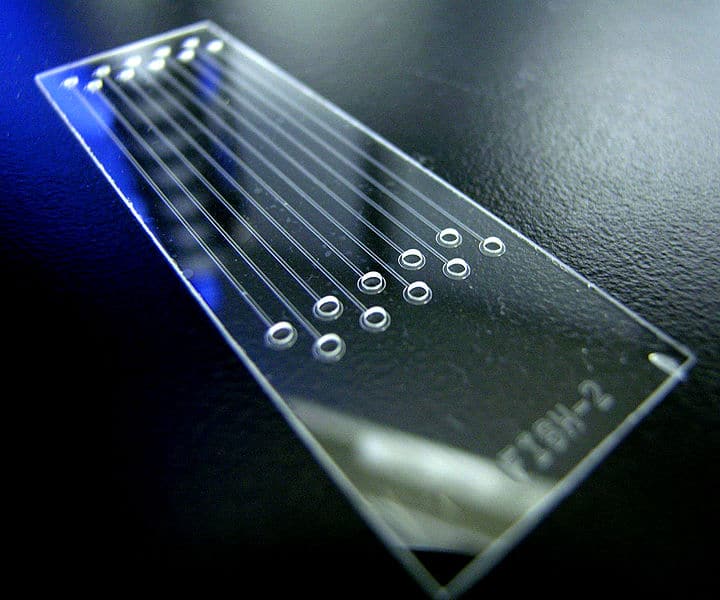

Microfluidic chips, often referred to as lab-on-a-chip devices, are miniature platforms that manipulate and analyze small volumes of fluids. These chips, witch feature molded or patterned micro-channels, integrate various functions, such as mixing, pumping, and sensing, onto a compact substrate, enabling precise control over minute amounts of liquids.

Inlet and outlet ports connect this network to the external environment. Liquids or gases can be injected, managed, and removed from the microfluidic chip through passive or active methods, wich may involve pressure/flow controllers, syringe pumps, or peristaltic pumps. The microscale fluidic chip’s channels may have varying inner diameters, typically ranging from 5 to 500 µm, but today’s fabrication techniques enable structures with sub-micrometer precision.

The channel network must be specifically designed for the desired application and analysis (cell culture, organ-on-a-chip, DNA analysis, lab-on-a-chip, microfluidic droplets, etc.).

A Brief History of Microlfuidic Chips

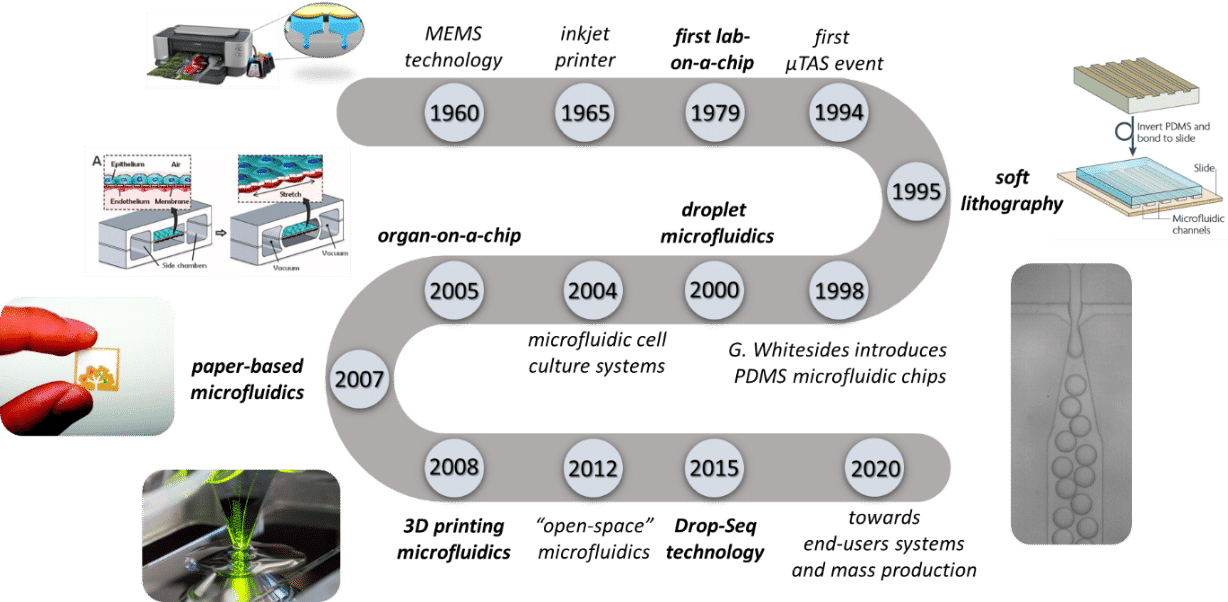

The roots of microfluidics trace back to the mid-20th century. However, it was in the late 20th and early 21st centuries that the field truly blossomed.

Miniaturization techniques have been continuously shaping the microelectronic’s technology and its ability to produce devices for a broad range of applications. Downscaling the dimensions of transistors has been pursued in the industry to fulfill the growing demand for smaller, faster and more energy-efficient systems1. In the late 1960s, a new field emerged known as microelectromechanical systems (MEMS).

This field laid the foundations for the miniaturization of mechanical systems, with the development of micromachining technology based on silicon semiconductor technology. It was during this era that engineers began realizing the capabilities of silicon chips in processing elements such as chemicals, motion, and light.

1950s-1970s: Early Developments

Pioneering work by scientists like Norbert Elmqvist and Andreas Manz laid the groundwork for microfluidic concepts.

1980s-1990s: Emergence of Lab-on-a-Chip

The term “lab-on-a-chip” gained prominence as researchers explored ways to miniaturize and integrate laboratory processes.

2000s-Present: Rapid Advancements

Microfluidic chips found applications in various fields, including biology, chemistry, and medicine, driving a surge in research and development.

Key Milestones:

First Lab-on-Chip (1979):

In 1979, the first glimpse of the future emerged as Andreas Manz pioneered the concept of a lab-on-a-chip, laying the foundation for a revolutionary era in microfluidics.

Polymerase Chain Reaction (PCR) on a Chip (1998):

The demonstration of PCR on a microfluidic chip by the Quake group showcased the potential for DNA amplification in a miniaturized format.

Organ-on-a-Chip (2010s):

Advancements in mimicking physiological conditions on microfluidic platforms led to the development of “organ-on-a-chip” devices, revolutionizing drug testing and disease modeling.

Point-of-Care Diagnostics (2010s):

Microfluidic chips played a pivotal role in the development of portable, rapid diagnostic devices, transforming healthcare by enabling on-site testing.

Drop-Sequencing protocol developed by Macosko et al. (2015)

Drop-Seq marked a significant milestone as it introduced a high-throughput method for single-cell RNA sequencing, propelling advancements in understanding cellular diversity and gene expression.

Material and production methods

Explore the world of microfluidic chip fabrication and production methods. These chips, crucial in lab-on-a-chip technology, are crafted from materials like silicon, glass, or polymers such as PDMS (Polydimethylsiloxane). The production methods vary, tailored to the chosen material.

The evolution of microfluidics traces back to the late 20th century with the development of inkjet printer heads. This breakthrough showcased the generation of micron-sized droplets using piezoelectric or thermal effects.

In 1990, Manz et al. introduced the concept of miniaturized total chemical analysis systems (μTAS)2, aiming to integrate diverse laboratory processes into a compact chip-sized platform.

This revolutionary idea sought to simplify and enhance complex chemical analyses by minimizing the size and complexity of traditional laboratory setups.

Subsequently, companies emerged, utilizing these systems for life science applications. The adoption of rapid prototyping and polymer replication, particularly PDMS, as an alternative to silicon processing, accelerated academic research. This era ushered in new terminologies such as “microfluidics” and “lab-on-a-chip” (LOC), reshaping the landscape of scientific exploration.

Microfluidic Chip manufacturers

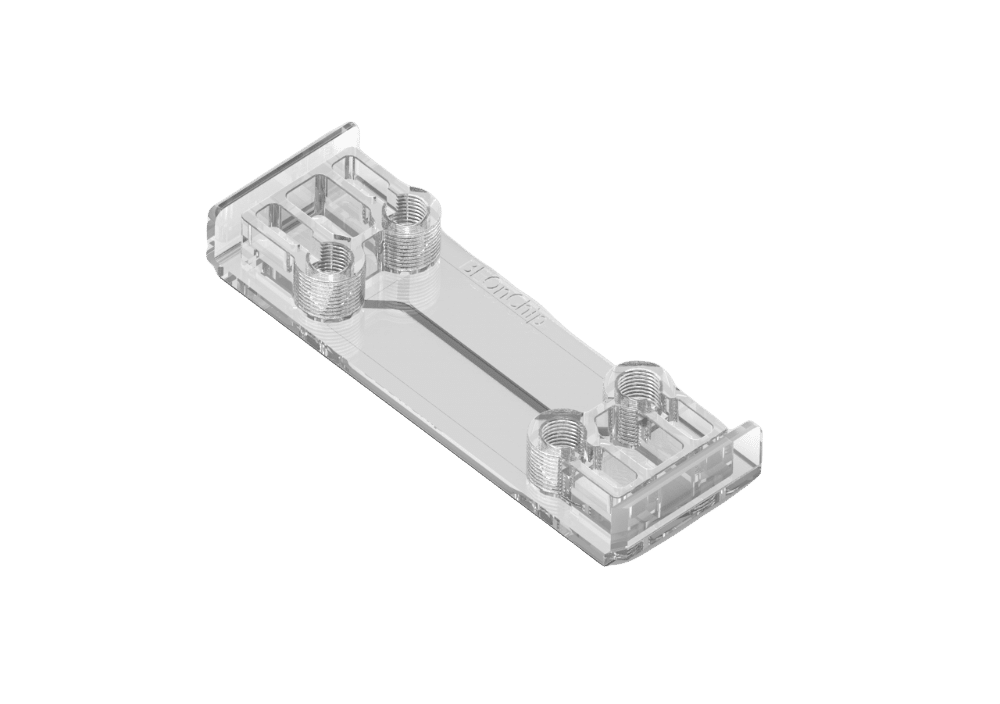

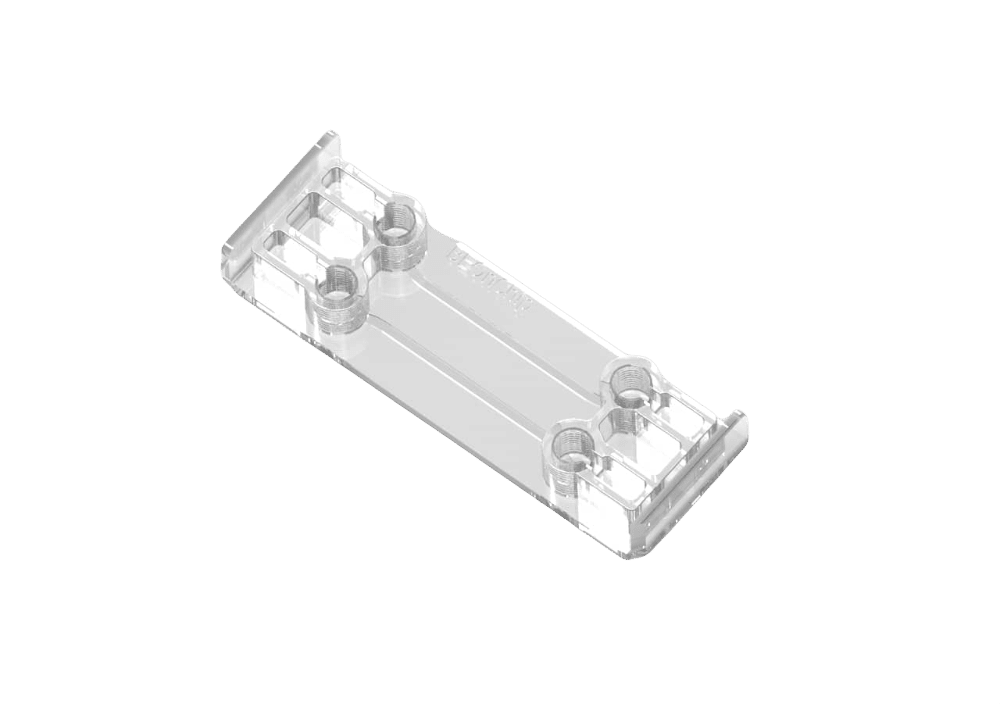

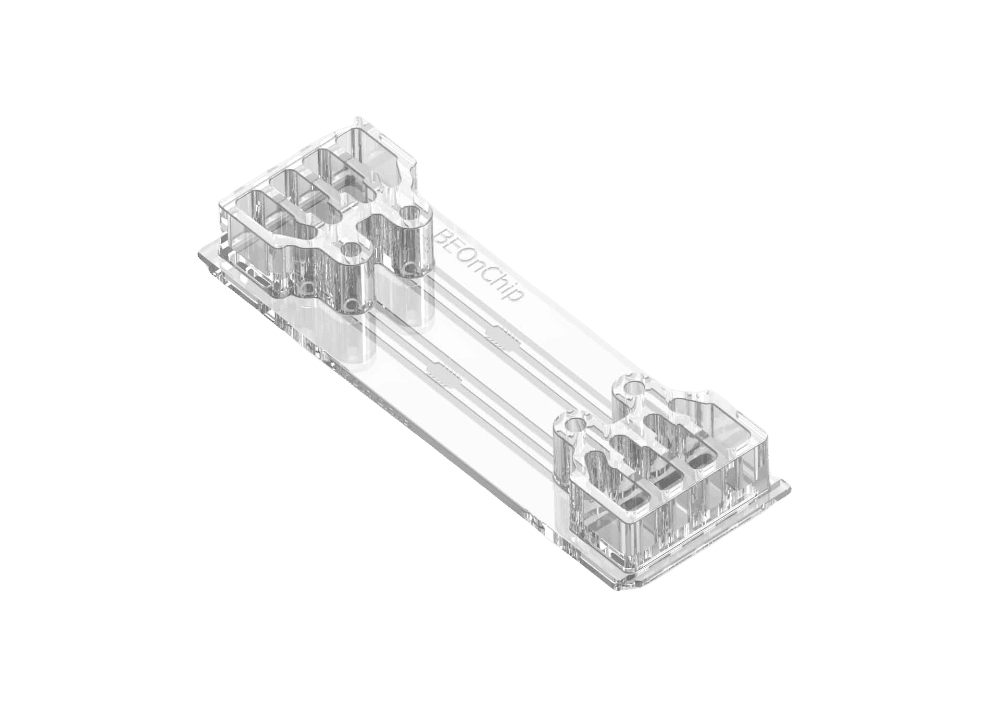

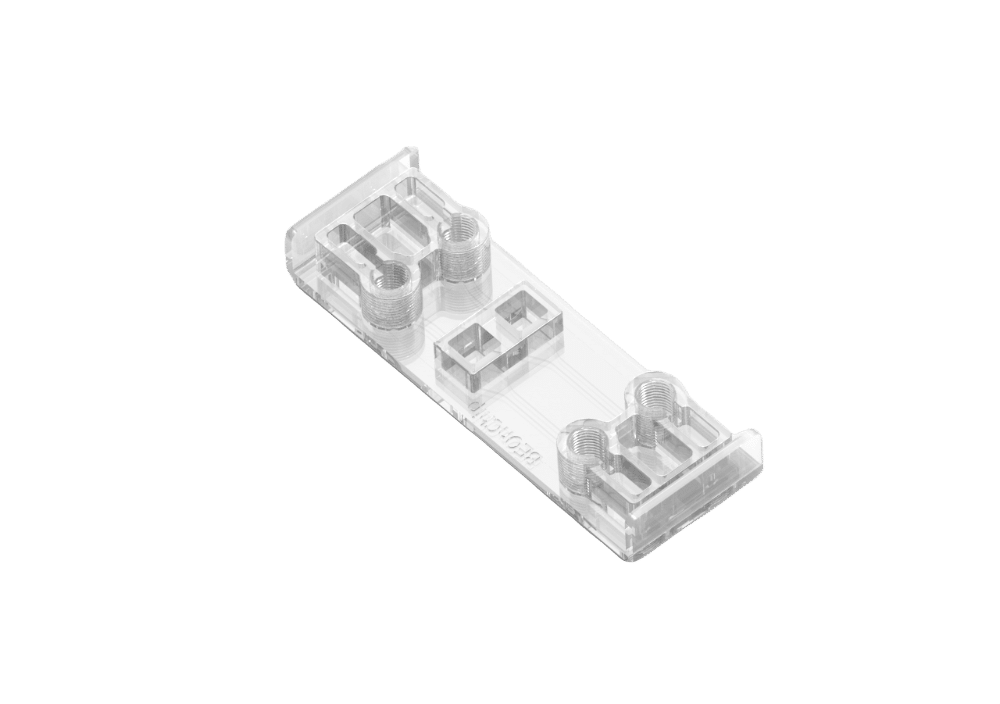

Beonchip S. L. was founded in 2016 at the University of Zaragoza by Ignacio Ochoa (specialist and PhD in biology), Luis Fernández (PhD in microtechnology) and Rosa Monge (PhD in mechanical Engineering).

Therefore, Beonchip have multidisciplinarity in its roots, and their team is proof of that. The collaboration of engineers and biologists has been key to design the most user friendly and accessible organ on chip devices that are true to the physiological environment of the body.

FlowJEM technology was developed for research and development projects by microfluidic researchers and engineers like you.

Microfluidic devices fabricated by FlowJEM have a broad range of applications, including but not limited to chemistry, materials science and technology, nanoscience, pharmaceutical science, biology, bioengineering and medicine.

FlowJEM’s goal is to meet the demands for high quality, fast turnaround time and low cost. Work with us to develop your ideas into prototypes or transition your prototypes to volume production.

Secoya Technologies develops innovative production technologies and equipment by a smart use of intensified operational units. It results in stable and reliable processes – at any scale – producing high quality (bio-)pharmaceutical products

Using cutting-edge technologies as sub-micrometric 3D printing and micro-electro-erosion, SECOYA has developed a unique device that is able to continuously produce micro-sized droplets at a very high frequency (kHz) and with a very narrow size distribution (high monodispersity). Its use for the encapsulation of active ingredients and multiple emulsions has been demonstrated.

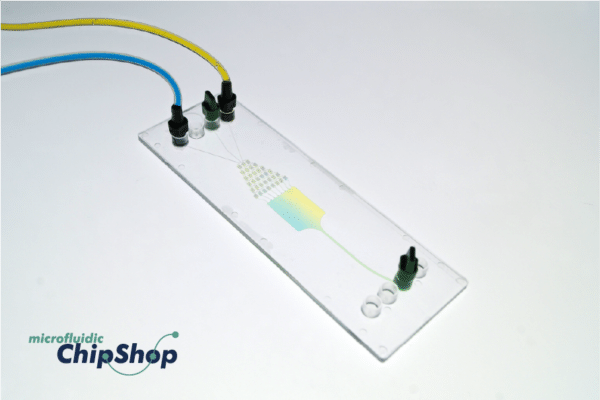

microfluidic ChipShop offers a wide off-the-shelf selection of microscale fluidic chips from thermoplastic polymers and the complementary accessories. They furthermore support customized prototyping as well as volume production services – from one to millions of chips, from simple microfluidic devices to complex lab-on-a-chip-systems.

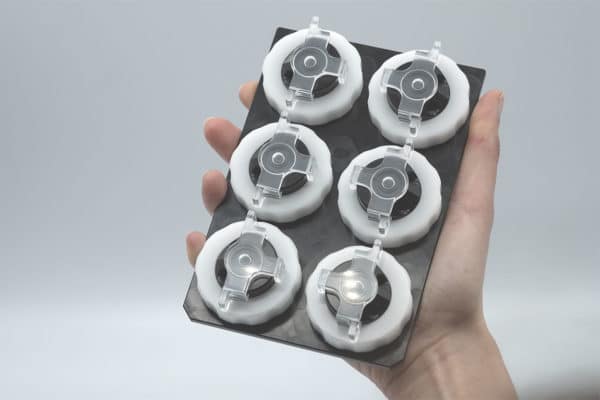

Bi/ond empowers biological innovation by engineering microchips which nourish, stimulate and monitor your cells. Bi/ond’s Organ-on-Chips are compatible with a wide variety of complex 3D tissues (organoids, patient-derived samples, cell monolayers) and they have been qualified in multiple applications such as Brain-on-Chip, Heart-on-Chip and Cancer-on-Chip. When you buy one of our OOC, you are not only purchasing a product, you are adding an engineer to your team. Bi/ond’ team will help and support you to set up your model with our extensive knowledge of microfabrication, simulations and biology.

Micronit is the leading innovator and global partner in design, development and manufacturing of customer specific lab-on-a- chip solutions for life science and health applications.

With over 20 years of experience, a highly qualified team, state-of-the-art technologies, and certified manufacturing facilities, we deliver innovative and competitive products to our customers for life science research towards personal health applications.

References

- Chiu, J. and Chie

- Temiz, Y., Lovchik, R. D., Kaigala, G. V. & Delamarche, E. Lab-on-a-chip devices: How to close and plug the lab? Microelectron. Eng. 132, 156–175 (2015).

- A. MANZ, N. G. and H. M. W. Miniaturized Total Chemical Analysis Systems: a Novel Concept for Chemical Sensing. Sensors and Actuators 17, 620–624 (1990).

Related Resources

- Expert Reviews: Basics of Microfluidics

Microfluidic Flow Control: Comparison between peristaltic, syringe and pressure pumps for microfluidic applications

Discover - Microfluidics White Papers

An exploration of Microfluidic technology and fluid handling

Discover - Expert Reviews: Basics of Microfluidics

Microfluidics overview: History and Definition

Discover - Expert Reviews: Basics of Microfluidics

Instrument Stability in Microfluidics

Discover - Expert Reviews: Basics of Microfluidics

How to choose a microfluidic chip

Discover - Expert Reviews: Basics of Microfluidics

Microfabrication of Microfluidic Chips: Materials and Methods

Discover - Expert Reviews: Basics of Microfluidics

Application of microfluidic chip technology

Discover - Expert Reviews: Basics of Microfluidics

The Raydrop | A new droplet generation device based on non-embedded co-flow-focusing

Discover - Microfluidic Application Notes

Automating Neuronal Cell Immunofluorescence in Microfluidic Chips

Discover