Extended Capabilities of Pressure Driven Flow for Microfluidic Applications

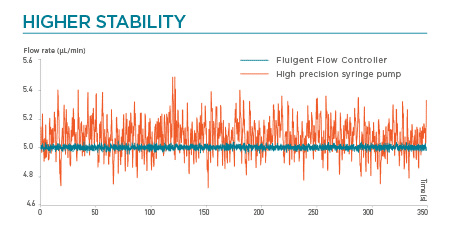

Fluid flow plays a fundamental role in scientific research, with microfluidics reintroducing key concepts of fluid dynamics. Among the different flow control methods, the pressure-driven flow rate is distinguished by its efficiency. The different types of flow, laminar, turbulent, transitional or sheared, dictate the behavior of fluids, especially within microfluidic chips, according to the Hagen-Poiseuille equation. While control methods such as syringes and peristaltic pumps often result in pulsating flows, pressure pumps offer superior stability and accuracy.

Fluigent pressure controllers, including the LineUp Flow EZ™ and MFCS™series offer advanced solutions for precise flow control. This precise flow control via pressure finds applications in various fields including microfluidic cell analysis, organ-on-a-chip technology, droplet and particle generation, and automated cell and tissue imaging.

Principle of “pressure driven flow”

In scientific research, the use of fluids still exists but the advent of microfluidics at the end of the 20th century reintroduced notions of fluid flow. There are several flow control methods available, but pressure is highly regarded.

Pressure driven flow refers to fluid movement through a system driven by a difference in pressure between two points. This flow occurs as the fluid moves from regions of higher pressure to lower pressure, following the established pressure gradient.

The pressure follows this equation:

ΔP=RQ

Q = flow rate ; ΔP = pressure difference; R = hydrodynamic resistance

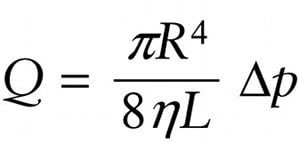

Flow is categorized into four types: laminar, turbulent, transitional, and sheared. When it is laminar and turbulence-free, flow follows the Hagen-Poiseuille equation, which considers other parameters. This law makes it possible to predict the behavior of fluids through a microfluidic chip.

Pressure is a solution to control the flow of fluids, but several other distinct methods can provide the same result.

Hagen-Poiseuille equation

Q = flow rate; ΔP = pressure difference; r = radius; L = channel length; η = viscosity of the fluid

What other solutions provide precise flow control via pressure?

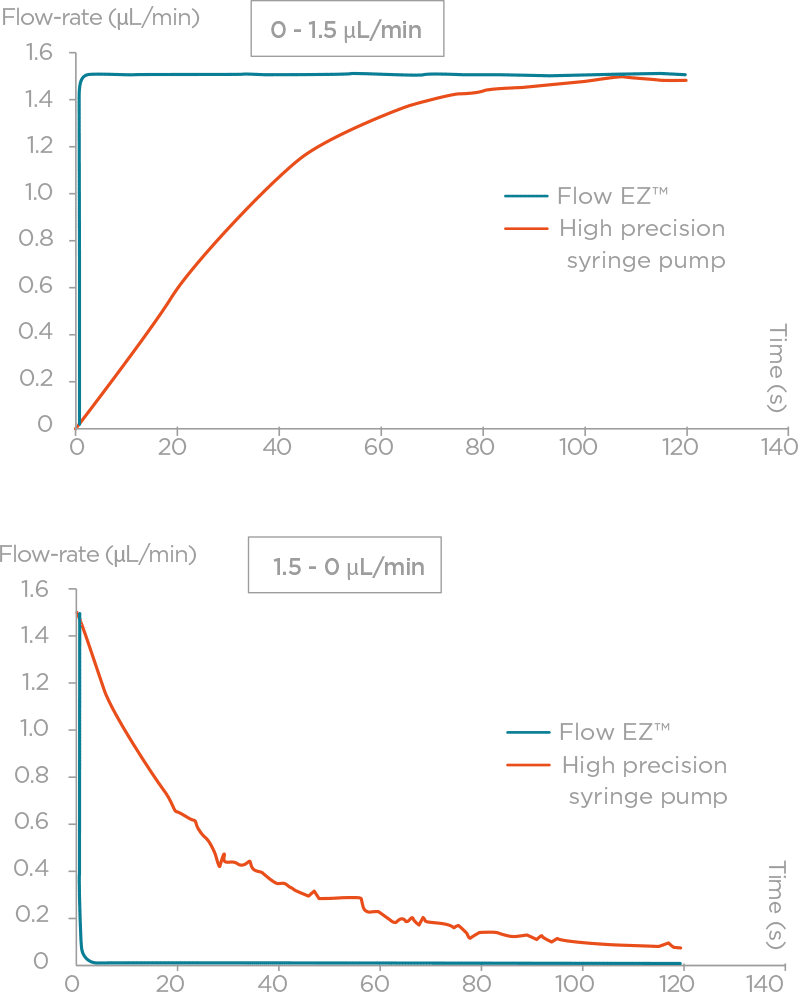

Selecting the appropriate pressure level is crucial for regulating the flow rate. Various methods can be employed to apply pressure, including syringe and peristaltic pumps, which rely on mechanical force. While these methods may produce pulsatile and erratic flows, pressure-driven pumps have demonstrated superior performance. A recent study tested the effectiveness of different pressure pumps, including: peristaltic pump, syringe pump and Fluigent pressure pump. See following results.

| Peristaltic pump | Syringe pump | Pressure pump | |

|---|---|---|---|

| Flow stability | Bad | Excellent | Excellent |

| Response time | Slow | Fast | Fast |

| Precision | Low | High | High |

| Contamination | Yes | No | No |

| Compactness | Yes | No | Yes |

| PC control | No | Yes | Yes |

| Sample accessibility | Yes | No | Yes |

| Temperature control | Yes | No | Yes |

Enhance your performance with Fluigent pressure controllers

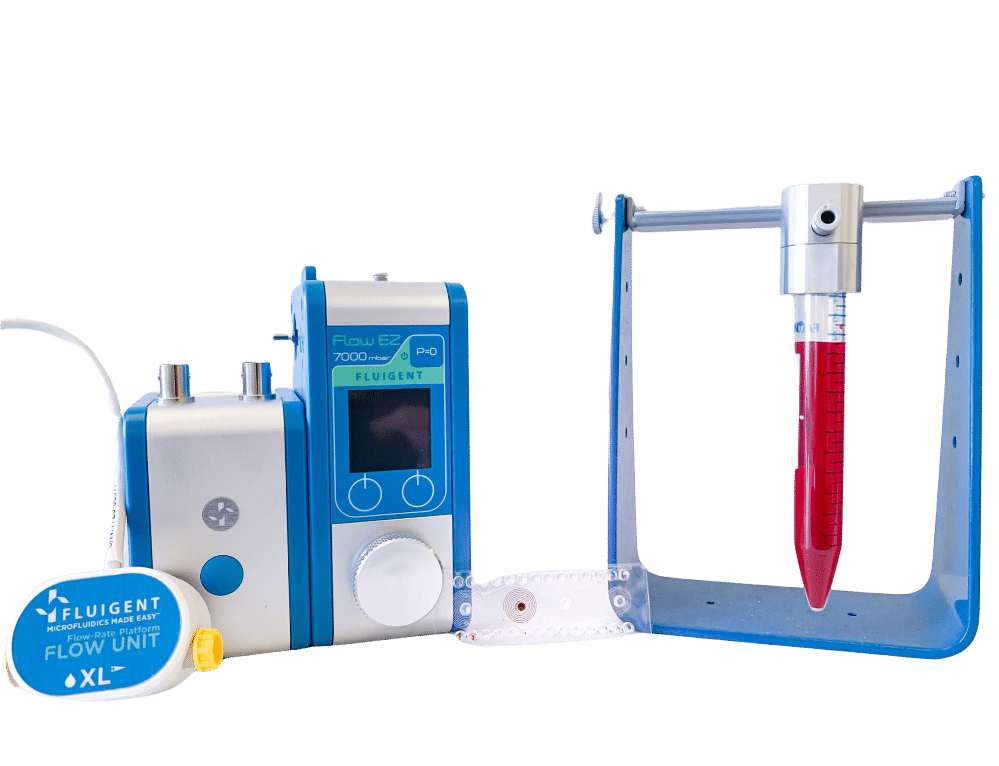

Flow EZ

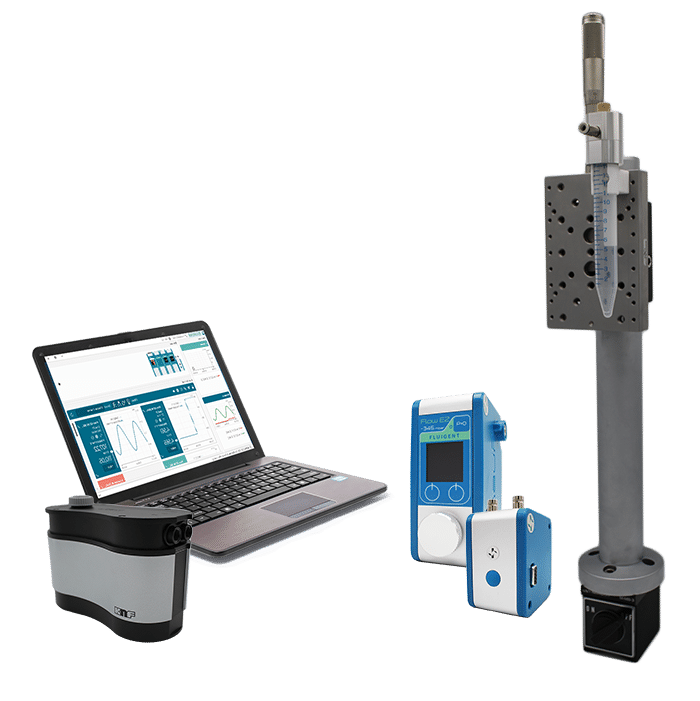

The LineUp Flow EZ™ is the pinnacle of pressure-based flow control systems. This compact device stands independently alongside the microfluidic setup, enabling users to conserve bench space without requiring a PC. With swift setup, the device quickly begins facilitating rapid data generation.

MFCS Series

The MFCS™ series comprises modular microfluidic flow controllers, available in 4 or 8 channel versions, and offers various pressure ranges tailored for precise operations in microfluidic experiments. The MFCS™ devices ensure a consistent pressure-driven flow rate, enabling dependable and reproducible experiments.

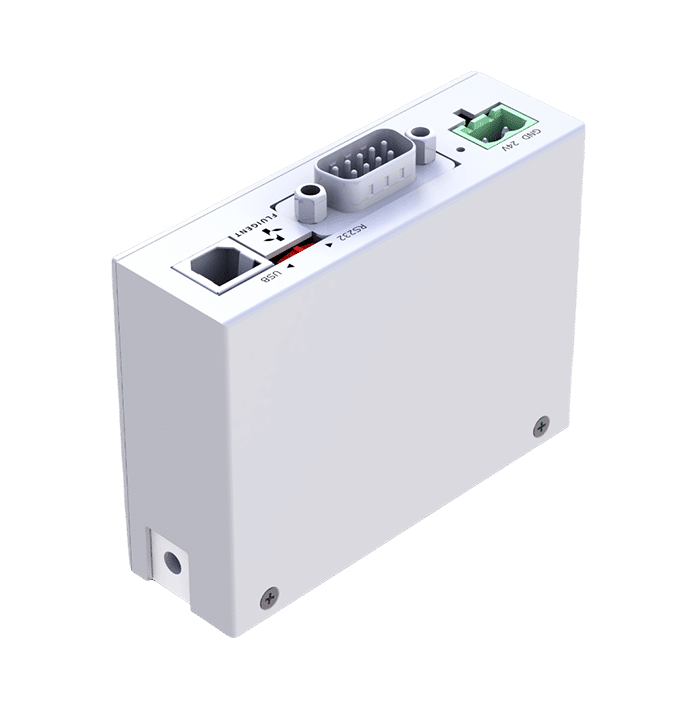

F-OEM: Integrated Flow Controller in your fluidic system

This OEM flow control module based on pressure actuation offers the right liquid handling specifications required for your device. We offer the widest pressure and flow rate range to support the most demanding industrial applications, including microfluidic and nanofluidic applications (microchannels, nanochannels, capillaries, lab on a chip, etc.).

What applications require pressure driven flow?

Precise flow control via pressure pumps has opened the door to a whole range of applications in several fields: microfluidics for cell analysis, Organ-on-a-Chip studies (OOC), droplet and particle generation, and automated cell and tissue imaging. These new applications contribute to the research and development of new diagnostic and therapeutic strategies by reducing reaction times, volumes, and costs.

Microfluidics for cell analysis

Microfluidics has modernized classical scientific research by replacing traditional methods with the study of liquids at the micrometric scale. The method has made it possible to reinvent techniques of cell analysis for understanding cellular interactions/behaviors. The techniques include:

- Micropipette aspiration, which requires precise flow control, making it possible to study the cellular response following a mechanical stimulus.

- Cell sorting within a microfluidic chip that receives fluids at different, well-controlled flow rates, allowing for easier and more affordable applications.

- Single cell analysis that offers high resolution and versatile, automated analysis to understand complex biological processes to develop new diagnostic and therapeutic applications.

Organ-on-a-Chip Studies

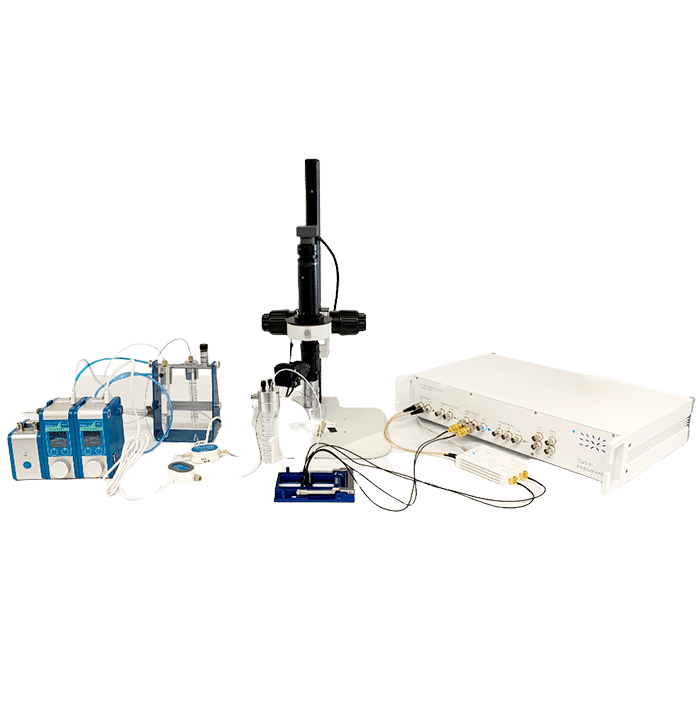

At a time when animal testing is on its way out, organ-on-a-chip studies is emerging as a revolution. They are defined as mimicking the functions of an entire organ or disease on a chip, thus reducing time and cost. They enable us to study drug delivery, regenerative medicine, and various types of therapy. However, this technology requires a special setup, especially for flow control. While peristaltic pumps cannot guarantee perfect flow due to back pressure, pressure controllers are essential tools for OOC applications. Controlling the entire process with software such as Oxygen provides high reactivity, stability, and flow precision within the organ-on-a-chip.

Droplet and particle generation

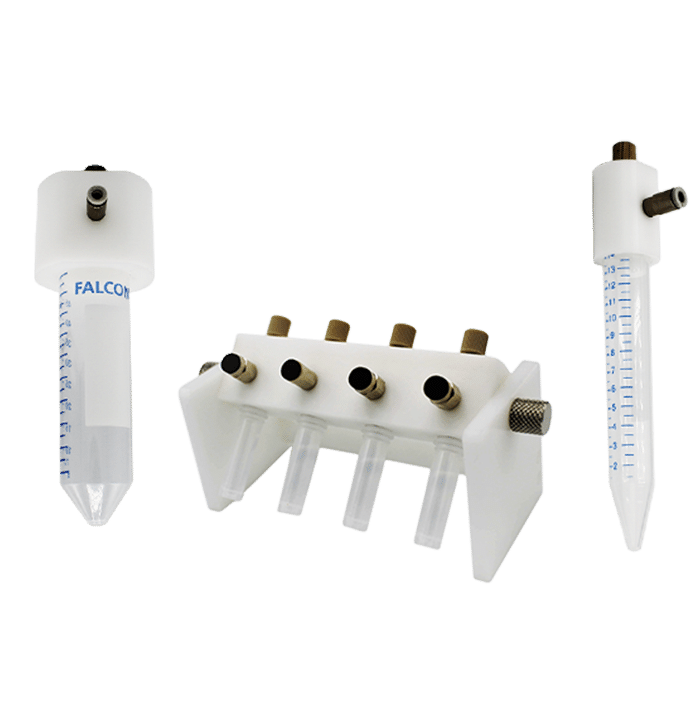

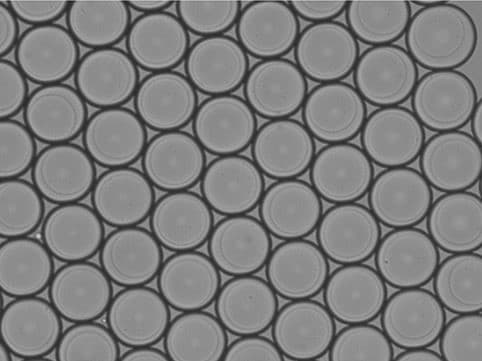

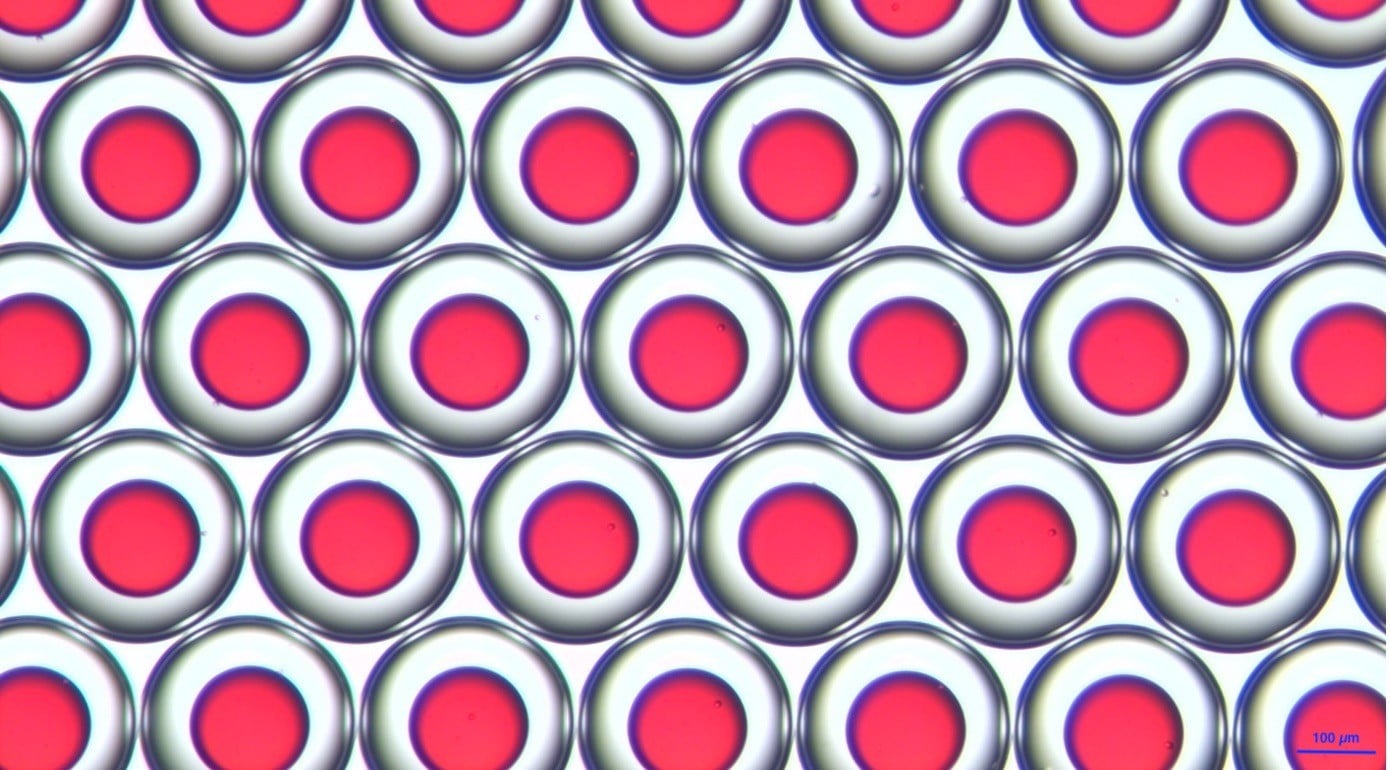

Droplets are playing an increasingly important role in the life science industry (think food, cosmetics, and particle synthesis) thanks to precise flow control that enables the generation of monodisperse droplets, which opens new applications such as digital PCR and single-cell encapsulation. These droplets are the result of mixing a continuous phase and a dispersed phase, each injected at a precise flow rate.

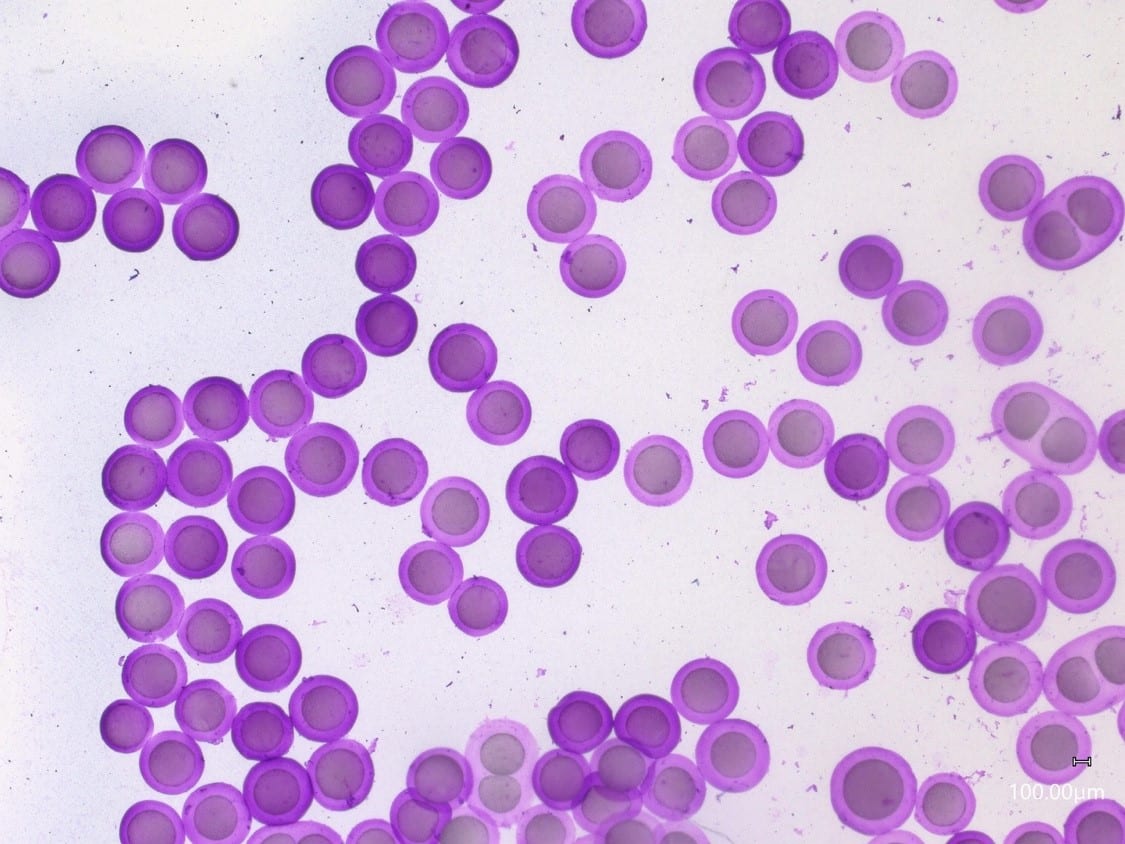

Pressure controllers have replaced syringe pumps which do not provide a stable flow rate and uniform droplet formation. The latter allows precise flow control, increasing reproducibility, droplet production frequency, and droplet size according to user requirements. With this approach, it is possible to create liposomes, Polymer Microparticles, and Microcapsules with high control of the size repeatability.

Alginate microbeads

Chitosan microcapsules

Agarose microcapsules

Automated cell and tissue imaging

Again, precise flow control by pressure has proven to be a superior method to the traditional syringe pump and has enabled the development of new automated imaging techniques for the study of cells and tissues. More reliable results open the door to the use of new, more realistic imaging methods. This is particularly the case with immunolabeling experiments, where microfluidics appears to be a much faster technique thanks to the addition of solutions that can now be automatically delivered homogeneously to optimize results, simplify execution, and save time.

Conclusion

Pressure driven flow is a crucial component of modern microfluidics, which allows for precise and efficient control of fluid movement at the microscopic scale. This approach offers significant advantages in terms of stability, responsiveness, and precision, paving the way for major advances in new areas.

Related products

Expertises & Resources

-

Microfluidics White Papers Double emulsion for the generation of microcapsules – a Review Read more

-

Microfluidic Application Notes Alginate Microcapsule Synthesis Read more

-

Microfluidic Application Notes Agarose Microcapsules Synthesis Read more

-

Expert Reviews: Basics of Microfluidics Why Control Shear Stress in Cell Biology? Read more

-

Expert Reviews: Basics of Microfluidics Micropipette aspiration of cells and tissues Read more

-

Microfluidic Application Notes Peristaltic Pump vs Pressure-Based Microfluidic Flow Control for Organ on Chip applications Read more

-

Microfluidic Application Notes Alginate Microbeads Production Read more

-

Microfluidic Application Notes Liposome Nanoparticle Synthesis Read more

-

Expert Reviews: Basics of Microfluidics High Throughput Single Cell Analysis Read more

-

Expert Reviews: Basics of Microfluidics Mimicking in-vivo environments: biochemical and biomechanical stimulation Read more

-

Expert Reviews: Basics of Microfluidics Flow control for droplet generation using syringe pumps and pressure-based flow controllers Read more

-

Expert Reviews: Basics of Microfluidics Pump Responsiveness in microfluidics Read more

-

Expert Reviews: Basics of Microfluidics Flow Control Technologies: Comparison between peristaltic, syringe and pressure pumps for microfluidic applications Read more

-

Expert Reviews: Basics of Microfluidics Microfluidics overview: History and Definition Read more

Related products

-

Compact Vacuum Pump Read

-

Compact Pressure Source Read

-

Microfluidic Recirculation Pack Read

-

Immunostaining Pack Read

-

Mechanical Stimulation Pack Read

-

Airtight pressurized bottle caps Read

-

Electrical Impedance Spectroscopy Pack Read

-

Micropipette Aspiration Package Read

-

Microfluidic Flow Control System Read

-

Microfluidic OEM Pressure Controller Read

-

OEM Microfluidic Pressure Source Read

-

Microfluidic Pressurized Fluid Reservoirs Read

-

Fully Custom Microfluidic Device Read

-

Microfluidic Size Cell Sorting Pack Read