Microfluidic Control of Complex Emulsions for Chemical Sensing

This case study explores a microfluidic approach to real-time chemical sensing using self-assembled complex emulsions. Formed with a tailored CNFCPEG molecule, a novel α-cyanostilbene core bearing a PEG chain for water solubility and a semi-perfluoroalkyl tail, the emulsions exhibit structure-dependent fluorescence for detecting iodine through visible color changes. The RayDrop microfluidic device, combined with the Flow-EZ™ for precise droplet formation and flow control, ensures consistent emulsion production and sensitive detection.

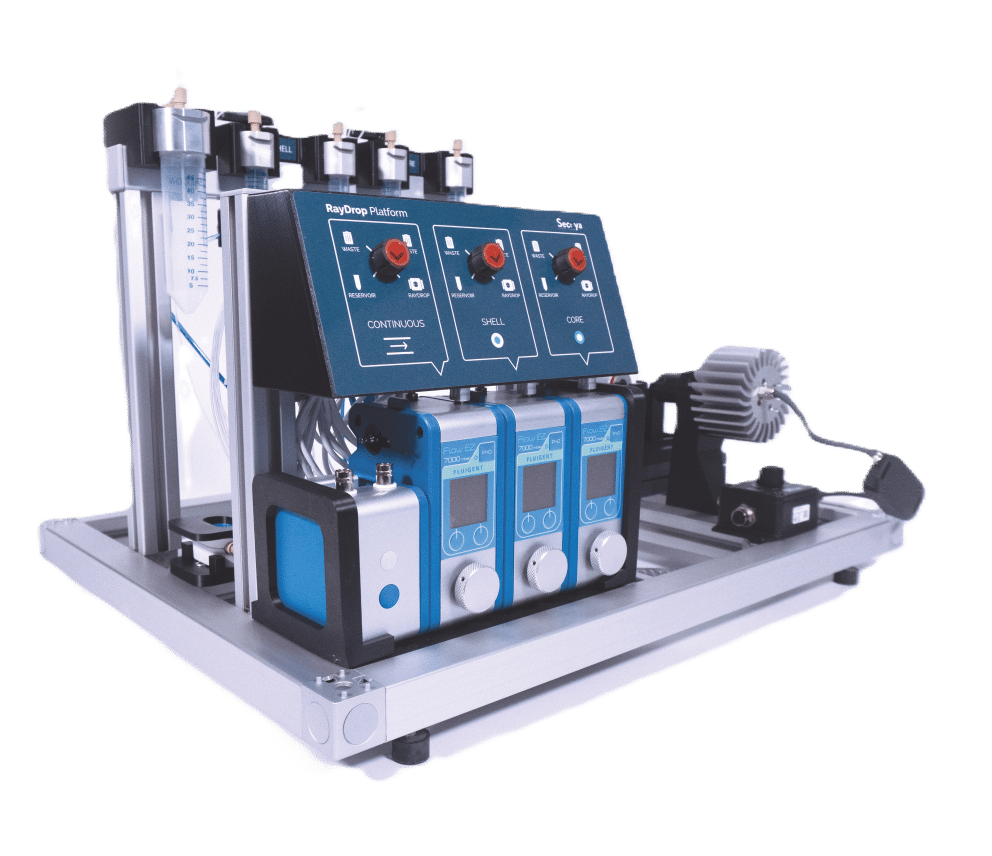

The RayDrop is developed and manufactured by Secoya Technologies

A Paper from the National Dong Hwa University

Rakesh, N., Tu, H.-L., Chang, P.-C., Gebreyesus, S. T., Lin, C.-J., Innovative Real-Time Flow Sensor Using Detergent-Free Complex Emulsions with Dual-Emissive Semi-Perfluoroalkyl Substituted Α-Cyanostilbene. Adv. Sci. 2023, 2304108.

This study is a collaboration between National Dong Hwa University and the Institute of Chemistry at Academia Sinica Nangang (Taiwan), led by Prof. Che-Jen Lin. His group focuses on three key areas: designing stimuli-responsive luminescent materials for sensing and bioimaging, developing organic porous frameworks for catalysis and energy storage, and creating soft materials integrated with microfluidic sensing for real-time detection and intelligent applications.

Learn more about the CJLin Group

Testimonial

“Our experience using the LineUp Flow EZTM pressure pump with the RayDrop chip has been positive. The pump’s high precision and accuracy have allowed us to achieve consistent and reproducible results in our microfluidic experiments. Additionally, the pump’s compact size and user-friendly interface have made integrating into our existing setup easy. The combination of Fluigent’s LineUp Flow EZTM pressure pump and RayDrop chip has great potential for advancing microfluidic research, and we are excited to continue exploring their capabilities in our ongoing studies.“

Che-Jen Lin, Ph.D., Assistant Professor at National Dong Hwa University. Organic Chemistry

Why generate complex emulsions?

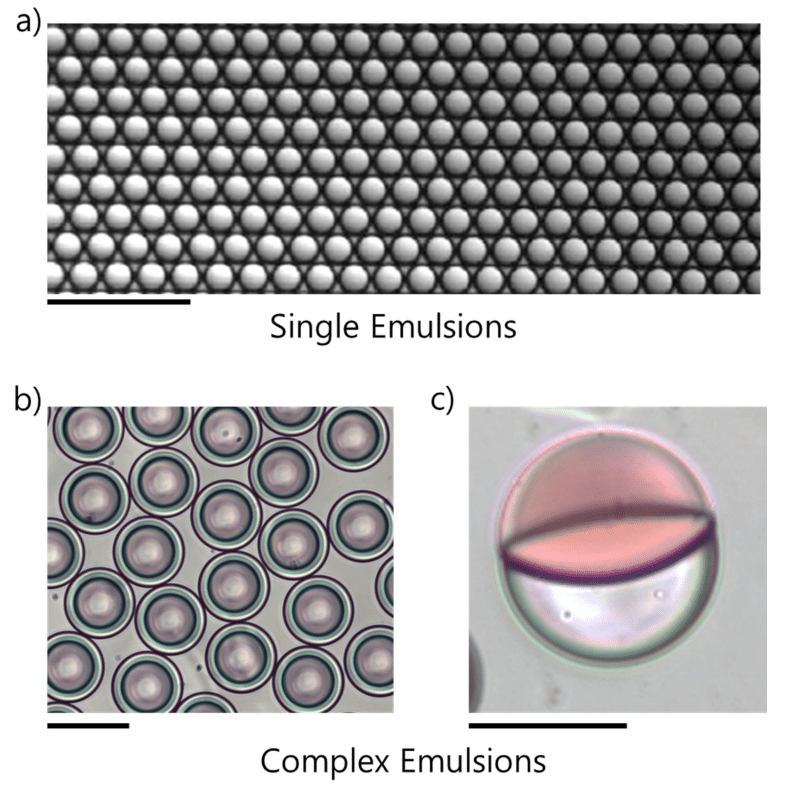

Emulsions are microscale spheroid structures formed by blending two immiscible liquids (often an oil phase and an aqueous phase). What differentiates complex emulsions (figure 1b) from simple emulsions (figure 1a) is their multi-layered structure.

Within a complex emulsion, micro droplets of one liquid are intricately dispersed within another, forming a heterogeneous droplet with exceptional properties. When properly generated and stabilized, complex droplets can be used to encapsulate active or reactive compounds, such as Active Pharmaceutical Ingredients,[2] or to design innovative functional particles. [3]

Some complex droplets can adopt temporary Janus configurations. Janus droplets have two distinct faces (figure 1c), each featuring unique properties achieved through selective surface modifications.[4] Their surface properties dynamically adjust over time or in response to external stimuli.

Generating complex droplets

Emulsion Setup

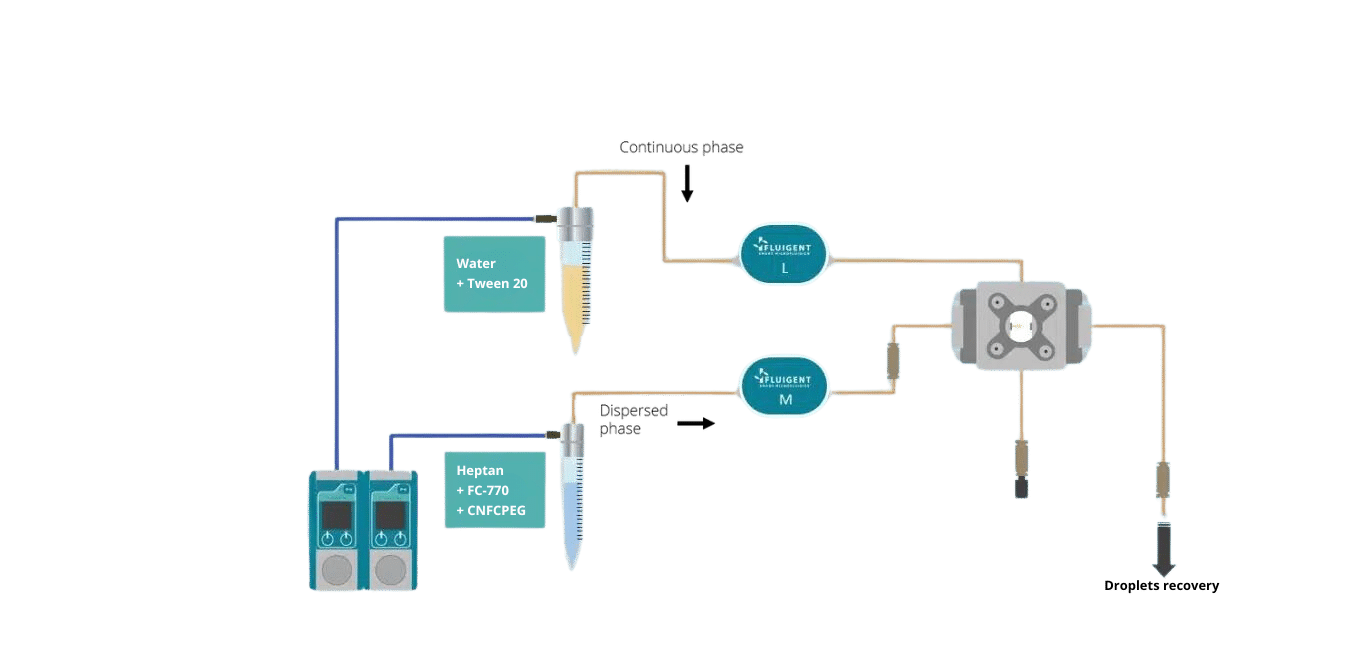

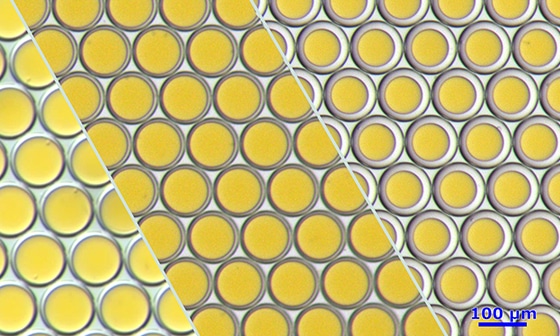

In this study, complex emulsions were generated with a mixture of hydrocarbon oil (heptane) and fluorocarbon oil (FC-770). To ensure a homogeneous solution, the mixture of heptane and FC-770 was heated above the upper critical temperature (50°C). 4×10-7 mmol of CNFCPEG was dissolved in 500µL of heptane and 500µL of FC-770.

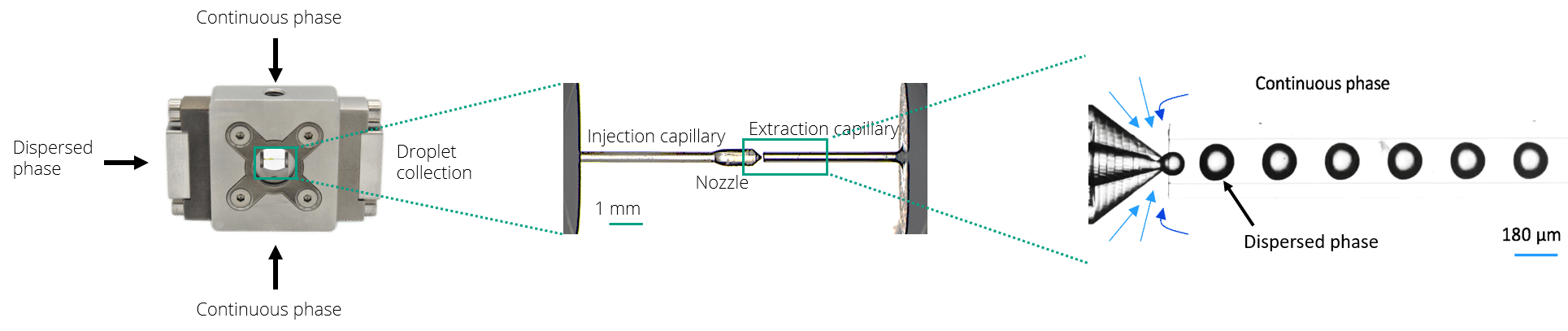

To generate complex emulsifications, the researchers employed Secoya’s single emulsion Raydrop coupled with Fluigent’s Flow EZTM flow controller to facilitate the creation of highly monodispersed droplets. Through this setup, they achieved precise control over pressures and flow rates, leading to the generation of controlled monodisperse droplets in the 50 to 80 µm range.

Raydrop Double Emulsion

Alternatively, an easier way to produce double emulsions is by using the new double emulsion Raydrop developed by Secoya. Thanks to its double nozzles, this new Raydrop can generate double emulsions in one step, creating a core-shell structure. The size of the core and shell can be precisely controlled, offering versatility in applications such as drug delivery systems.

Using complex emulsions to measure iodine concentration

The key role of CNFCPEG

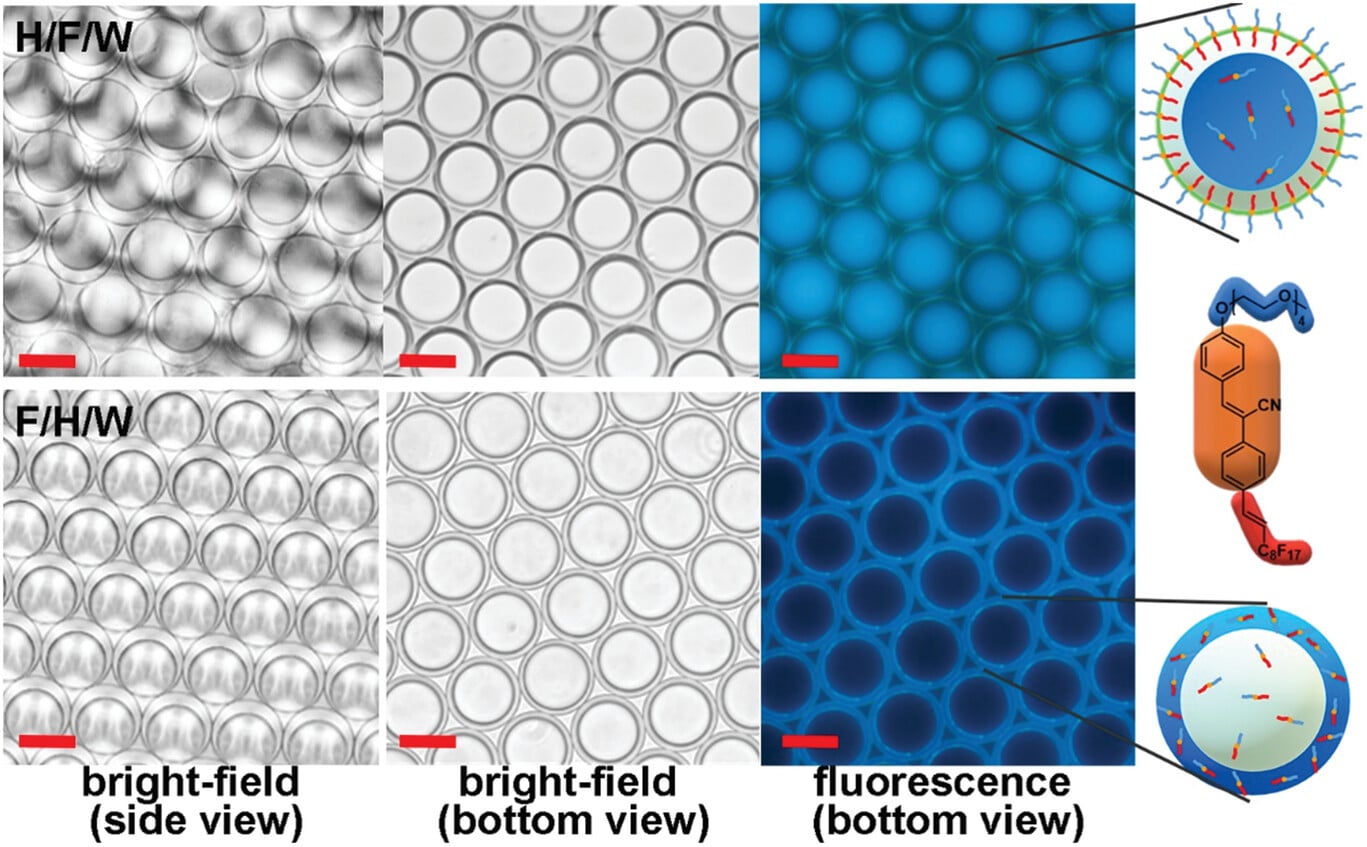

In this study, CNFCPEG, an innovative compound, plays a major role in stabilizing complex emulsions without the need for external surfactants. CNFCPEG also exhibits two fluorescence colors (blue and green) depending on its aggregation state. When CNFCPEG aggregates in an organic phase, a blue color is observed, while the green excimer is observed when CNFCPEG self-assembles at the fluorinated oil/water interface (F/W). By evaluating fluorescence emissions, the distinction between H/F/W and F/H/W emulsions becomes clear and easily distinguishable.

Heptane-FC 770-CNFCPEG complex emulsion in DI water presents the H/F/W morphology. Addition of iodine to the DI water reduces the hydrophilicity of CNFCPEG’s PEG group, leading to an instantaneous morphology shift from H/F/W to Janus to F/H/W complex emulsion. This morphological shift, combined with the fluorescent color change, makes it possible to to detect the presence of iodine in water.

Complex droplets as iodine real-time sensing platform

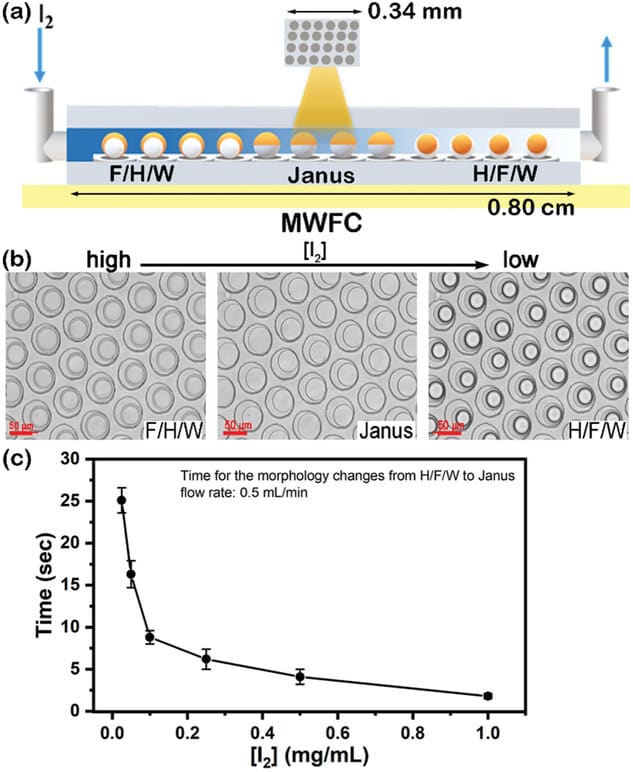

To enhance the precision and accuracy of data acquisition in real-time flow sensing, the researchers designed a Multiple-well Flow PDMS Chip (MWFC) that allows for parallel tracking of multiple droplets (figure 6). This innovative chip facilitates the monitoring of droplet behavior, morphological changes, and interactions within complex droplets.

Iodine was injected into the MWFC, inducing a decrease in the hydrophobic nature of the CNFCPEG and initiating an instantaneous morphological change in the stabilized complex droplets (figure 7b, figure 8). The droplets transitioned from H/F/W to Janus more quickly with increasing iodine concentration. Slower flow rates corresponded to longer transition times, providing quantitative insights into analytes (figure 7c).

Webinar Replay

Complex Microfluidic Emulsions: Optimize Production, Flow Control & Monodispersity

Get the best of Flow Control Technologies to perform highly monodispersed droplets. Learn everything you need in our webinar recording.

✅ Precision in Emulsion Creation using the RayDrop from Secoya

✅ Mastering Flow Control through Flow EZ Pressure pump from Fluigent

✅Case Study: Fluorescent Complex Emulsions with Prof. Che-Jen Lin from Associate Professor – National Dong Hwa University

Conclusion

In this case study, amphiphilic α-cyanostilbene CNFCPEG stabilized complex emulsions without the need for external surfactants, exhibiting morphology-dependent fluorescence that allowed for real-time iodine sensing through visible emission color shifts.

By integrating the RayDrop for precise droplet formation and FlowEZ for accurate flow control, this system enabled consistent and reproducible sensing without the need for bulky equipment.

The results highlight the potential of this approach for developing portable, real-time chemical and biological sensing technologies, offering an approach for on-site monitoring in fluid environments

Related products

Discover key reviews covering into the potential and techniques behind double emulsion microfluidics

- Microfluidics White Papers

An exploration of Microfluidic technology and fluid handling

Read more - Microfluidics White Papers

Droplet-based Microfluidics – A Complete Guide

Read more - Expert Reviews: Basics of Microfluidics

10 Tips for Reliable Droplet Generation

Read more - Expert Reviews: Basics of Microfluidics

Microfluidics in Drug Delivery: A New Era of Precision Medicine

Read more

Related Resources

-

Microfluidic Application Notes 1-10 microns PLGA microsphere production using the RayDrop Read more

-

Microfluidic Application Notes A quick and efficient double encapsulation method for FACS-based droplet sorting Read more

-

Microfluidic Application Notes PLGA nanoparticle synthesis using 3D microfluidic hydrodynamic focusing Read more

-

Microfluidic Application Notes Encapsulation of multiple emulsions in a single droplet Read more

-

Microfluidic Application Notes Alginate Microbeads Production Read more

-

Microfluidic Application Notes Water in Oil Emulsions Read more

-

Microfluidic Application Notes Oil in Water Emulsions Read more

-

Expert Reviews: Basics of Microfluidics Flow control for droplet generation using syringe pumps and pressure-based flow controllers Read more

-

Expert Reviews: Basics of Microfluidics Flow Control Technologies: Comparison between peristaltic, syringe and pressure pumps for microfluidic applications Read more

References

[1]Rakesh, N., Tu, H.-L., Chang, P.-C., Gebreyesus, S. T., Lin, C.-J., Innovative Real-Time Flow Sensor Using Detergent-Free Complex Emulsions with Dual-Emissive Semi-Perfluoroalkyl Substituted Α-Cyanostilbene. Adv. Sci. 2023, 2304108. https://doi.org/10.1002/advs.202304108

[2]Linghao Qin, Yawei Niu, Yuemin Wang, and Xiaomei Chen, Molecular Pharmaceutics 2018 15 (3), 1238-1247, DOI: 10.1021/acs.molpharmaceut.7b01061

[3]Justin R. Finn, Janine E. Galvin, Modeling and simulation of CO2 capture using semipermeable elastic microcapsules, International Journal of Greenhouse Gas Control, Volume 74, 2018, Pages 191-205, ISSN 1750-5836, https://doi.org/10.1016/j.ijggc.2018.04.022.

[4]Bradley D. Frank, Markus Antonietti, and Lukas Zeininger, Macromolecules 2021 54 (2), 981-987, DOI: 10.1021/acs.macromol.0c02152