Generating a water emulsion in an oil solution using a droplet generator chip

Microfluidic droplet generation has attracted a lot of interest due to this method’s ability to produce highly monodispersed droplets with high frequency (up to hundreds of kHz).

Interest in droplet-based microfluidic systems has grown substantially in the past decade as they offer the ability to handle very small volumes (ranging from µl to fl) of fluids conveniently, providing better mixing, encapsulation, sorting and sensing, as well as suitability for high-throughput experiments. Microfluidic-based droplets have many diverse and varied applications, including particle synthesis and chemical analysis. Highly controlled droplet production also makes single-cell analysis or drug testing possible.

Advantages of droplet-based microfluidics for water emulsions

Droplet-based microfluidics offers several advantages specifically tailored to water emulsions:

- Reduced Sample Volume: Microfluidic devices handle small sample volumes efficiently, minimizing waste and reducing costs associated with reagents and materials.

- High monodispersity: This method produces water emulsions with high monodispersity, ensuring consistency and reliability in experiments and applications.

- High Throughput: Droplet-based systems can generate water emulsions at high throughput, facilitating rapid experimentation and scale-up processes.

- Precise Control: Microfluidic platforms enable precise control over droplet size, composition, and encapsulation, crucial for creating uniform water emulsions.

- Encapsulation of Active Agents: Microfluidic emulsification enables precise encapsulation of active agents within water droplets, facilitating controlled release and targeted delivery in applications such as drug delivery or cosmetics.

In general, applications of microfluidic droplets arise from two distinct but complementary aspects. One exploits droplets with well-defined components and structures as templates in materials science, e.g., synthesis of microcapsules, microparticles, and microfibers with applications in pharmaceuticals, cosmetics, and foods; another involves lab-on-a-chip applications where droplets are used as microreactors to perform chemical and biochemical reactions. (1)

What is a water-in-oil emulsion?

Production of oil-in-water or water-in-oil emulsions is based on the use of two immiscible phases that are referred to as the continuous phase (medium in which droplets flow) and the dispersed phase (the droplet). For generating droplets, microfluidic systems generally include a PDMS microfluidic chip, a fluid handling system, and tubing. This system is usually connected to a computer and a microscope to visualize droplet formation.

Reliable generation of droplets with accurate control over their size and size distribution is therefore of vital importance to meet the increasingly high demands in various applications. To this end, it is critical to have a deep and systematic understanding of microfluidic droplet formation, including both passive and active techniques (2).

Fluigent develops, manufactures, and supports innovative fluid-handling solutions for a variety of applications using microfluidic droplet generation.

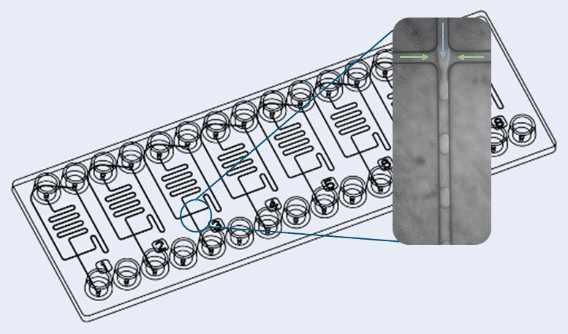

The objective of this application note is to generate a water emulsion in an oil solution using the Fluigent microfluidic system including pressure pumps, chemicals, tubing and a Droplet Generator PDMS Chip obtained from our partner, microfluidic ChipShop.

Materials and methods

Reagents

Continuous phase: dSurf 2% diluted in 3M™ Novec™ 7500

Dispersed phase: Distilled water

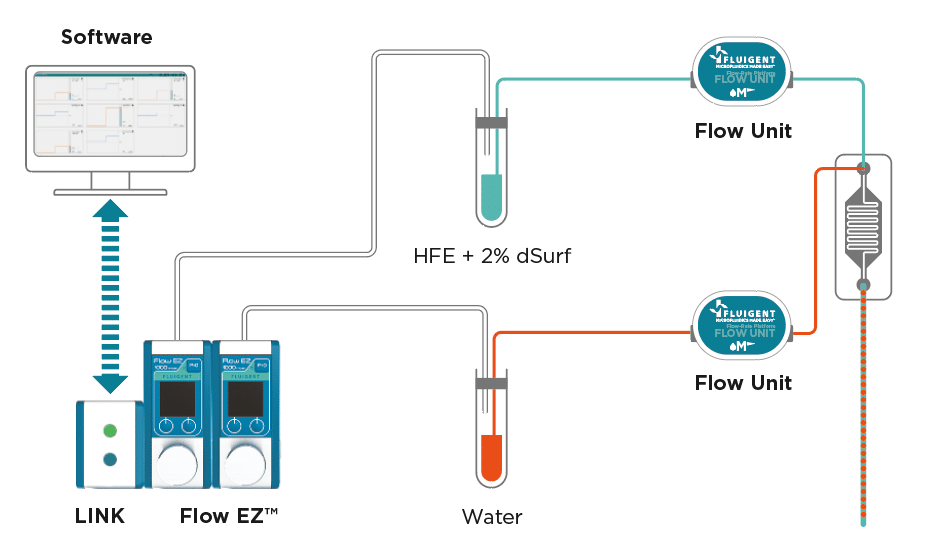

How to generate water-in-oil emulsions

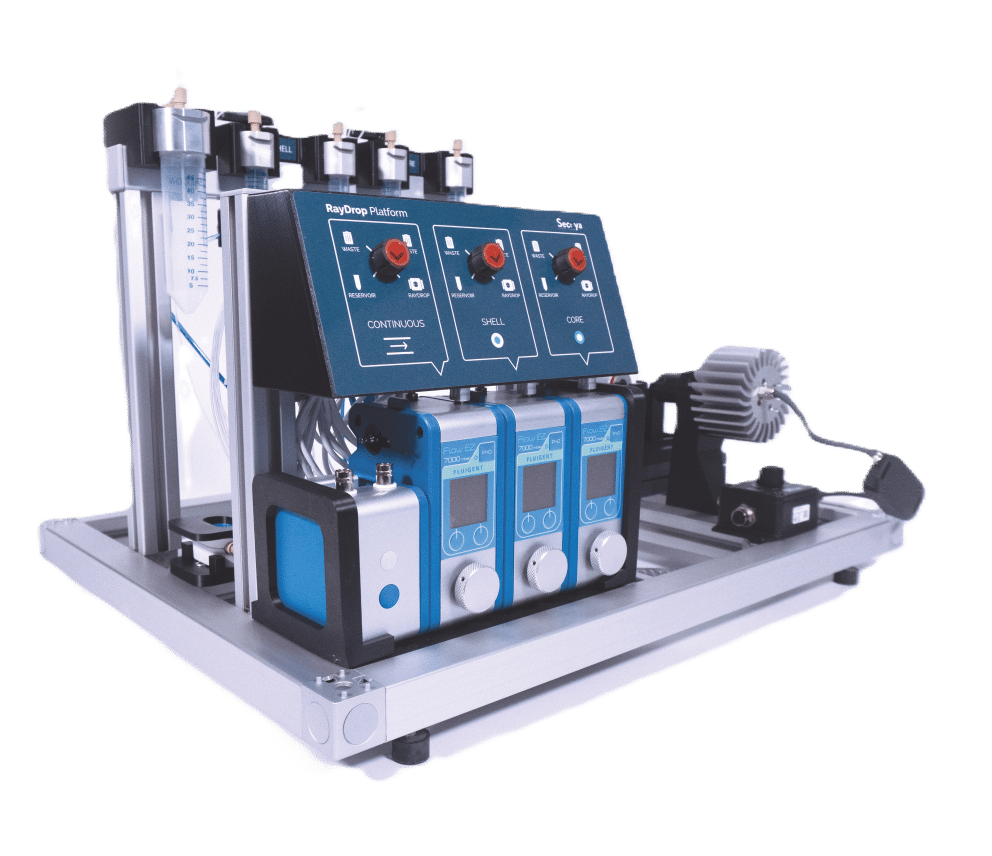

An external pressure source is connected to two Flow EZ pressure pumps that are connected to the microfluidic ChipShop chip via tubing. The tubing passes through Flow units to measure pressure and flow rate. Visualization of the chip channels is performed using an optical microscope. A LINK can connect the Flow EZ module to a PC to monitor pressure and flow rate in real-time.

Results of the water-in-oil emulsion generation experiment

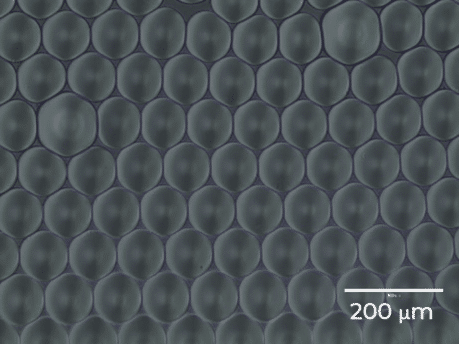

We generated water-in-oil emulsions (W/O) using the microfluidic system presented in Figure 1.

Two 15 mL reservoirs containing water and 2% dSurf are connected to the two inlets of the PDMS microfluidic chip via 1/32 in. PEEK tubing with an inner diameter of 254 µm.

The tubing passes through flow units allowing flow rate measurement and control. The length of the tubing from the reservoir to the microfluidic chip is 80 cm. Pressure is applied using the Flow EZs on the reservoirs containing distilled water and dSurf.

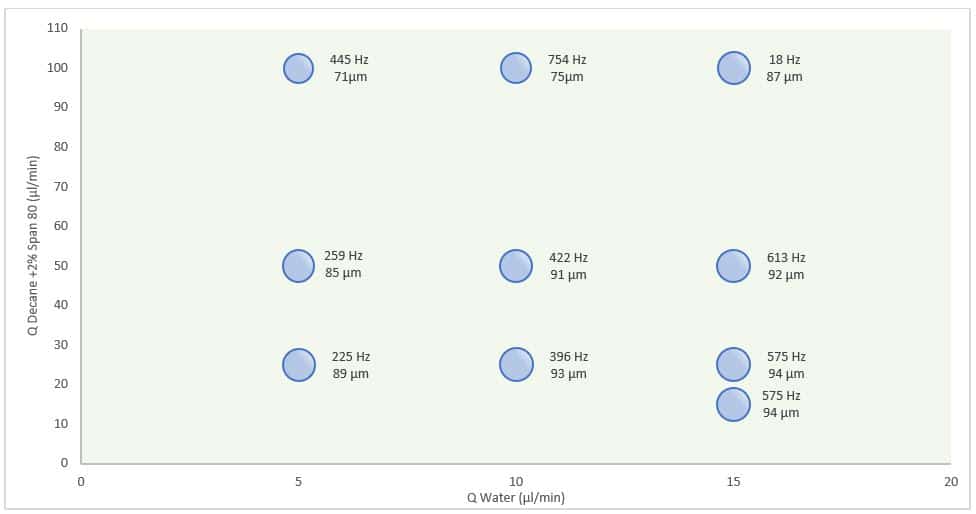

Water is injected in the inner channel and dSurf is injected in the surrounding channel of the microfluidic device. The pressure applied ranges from 100 to 300 mbar. This may vary depending on the size and frequency we want to achieve in our water-in-oil emulsion generation experiment. Visualization of the chip channels is performed using an optical microscope. A LINK can be connected to the Flow EZ module and a PC to monitor pressure and flow rate in real-time.

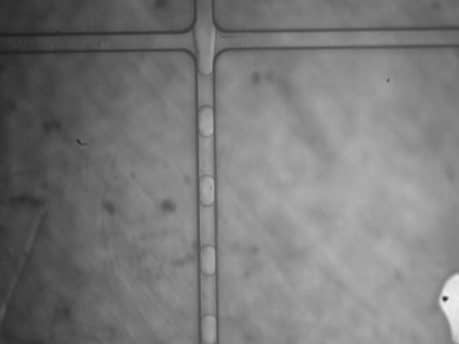

As seen in Figure 4, by using this range of flow rates controlled by Flow EZs with the ChipShop microfluidic droplet generator, it is possible to obtain droplets with diameters ranging from 80 µm to 160 µm, and with generation rates ranging from 50 Hz to 250 Hz.

Conclusion

We have demonstrated the use of Fluigent pressure pumps combined with microfluidic ChipShop’s PDMS chip to generate a water-in-oil emulsion. The versatility of the system allows users to easily produce droplets of different diameters and at multiple generation rates. Droplets generated with this system are suitable for many applications, including those that require biocompatibility.

For more information about the microfluidic chip droplet generator, visit the ChipShop website at www.microfluidic-chipshop.com, or contact them by e-mail at inquiries@microfluidic-ChipShop.com

REFERENCES

- Zhu, P. and Wang, L. (2017) “Passive and active droplet generation with microfluidics: A Review,” Lab on a Chip, 17(1), pp. 34–75. Available at: https://doi.org/10.1039/c6lc01018k.

- Tan, Y.-C., Cristini, V. and Lee, A.P. (2006) “Monodispersed microfluidic droplet generation by shear focusing microfluidic device,” Sensors and Actuators B: Chemical, 114(1), pp. 350–356. Available at: https://doi.org/10.1016/j.snb.2005.06.008.

Related Products

Expertises & Resources

-

Microfluidics White Papers Double emulsion for the generation of microcapsules – a Review Read more

-

Microfluidics White Papers Droplet-based Microfluidics – A Complete Guide Read more

-

Microfluidic Application Notes Water in Fluorocarbon Oil Emulsions Read more

-

Microfluidic Application Notes Water in Oil Emulsions Read more

-

Microfluidic Application Notes Oil in Water Emulsions Read more

-

Expert Reviews: Basics of Microfluidics Microfluidic Droplet Production Method Read more

-

Expert Reviews: Basics of Microfluidics Flow control for droplet generation using syringe pumps and pressure-based flow controllers Read more