Droplet and particle manipulation using electrophoretic flow control

Many microfluidic applications are developed based on concepts relying on electrodes, exploiting the electrical properties of samples to sort or separate them, generate electro-osmotic flows, manipulate particles, perform electrochemical detection etc. One example of this is electronic paper, where the electrophoretic displacement of titanium dioxide particles in a dark hydrocarbon oil solution allows the formation of a black and white pattern with a high resolution.

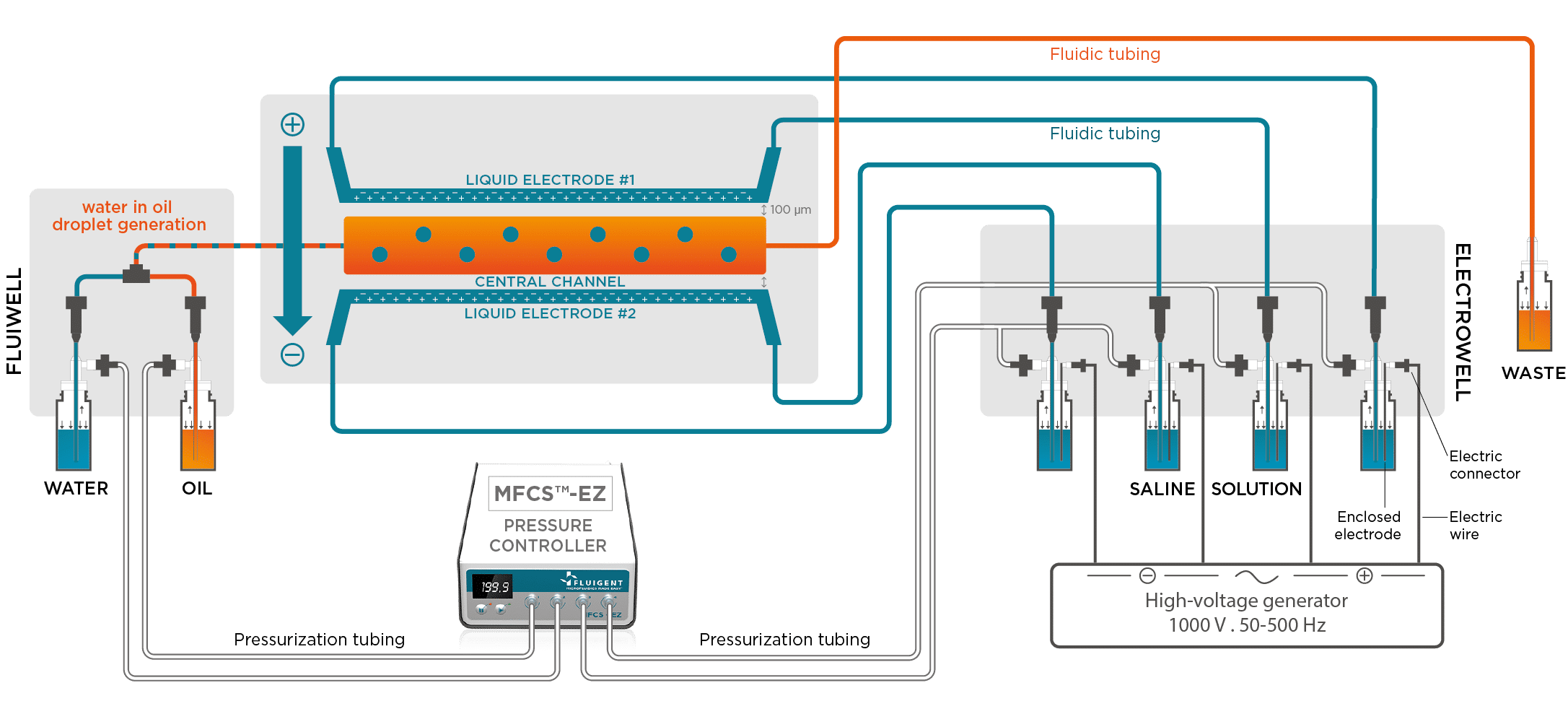

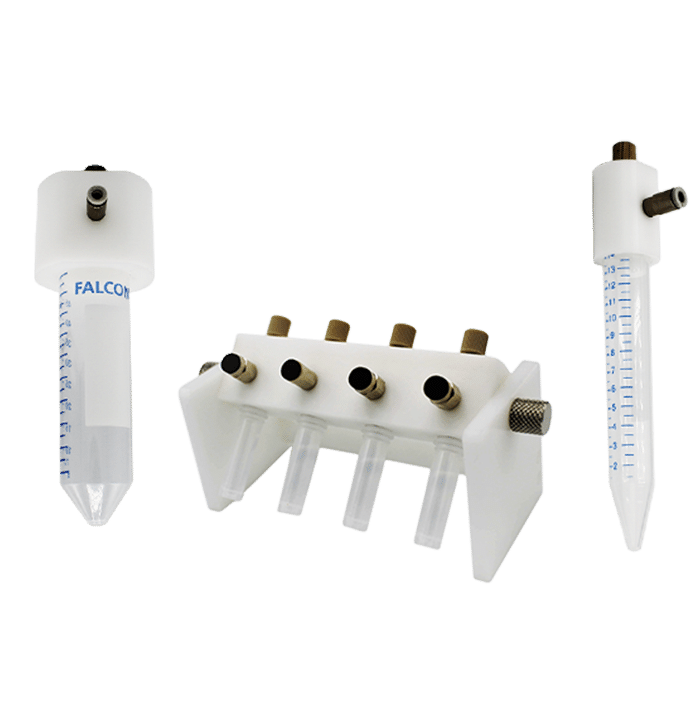

Most of the time, this implies complex microfabrication processes to build embedded electrodes inside the microfluidic chip. This can be avoided by the use of Fluigent’s Electrowell device, which combines pressurized fluid reservoirs with a choice of electrodes. These charged reservoirs can be simultaneously connected to an MFCS™-EZ pressure controller and a high voltage generator in order to generate both a pressure-driven flow and/or an electroosmotic flow in the fluid.

This application note explains how a droplet manipulation setup using embedded conventional indium electrodes could be replaced with a microchip using Electrowell-generated liquid electrodes, with a simpler design that provides enhanced performance.