Double Emulsion Generation

Double emulsion could be defined as a droplet encapsulated within a larger droplet of different immiscible phases. Double emulsion generation is a promising method for many academics [1][2] as industrial fields such as in cosmetics for fragrance manufacturing [3] [4] [5], in food application for flavor manufacturing, food supplement encapsulation such as vitamin and taste masking [6] [7], in pharmaceutics for drug delivery (protection of Agent Pharmaceutical Ingredient in microcapsules for control drug release) and other…[8] [9]

Whereas double emulsion is a promising method for many applications, double emulsion production technologies such as batch methods are all suffering from various limitations such as poor size distribution, multiple-step process, and low reproducibility… [6] [8]

In this application, we are going to present our pack, a complete system for producing monodisperse double emulsions, with a robust capillary-based device that allows single-step production of double emulsion with a single device, the RayDrop developed and manufactured by Secoya.

Different examples of double emulsion (w/o/w and o/w/o) have been generated to show the versatility and adaptability of the Raydrop to multiple applications such as Polymer and Hydrogel microcapsules for drug delivery or for encapsulation of cells for FACS sorting as well.

Secoya developed and manufactured the RayDrop used to perform this application note.

What is double emulsion generation?

Double emulsion, water-in-oil-in-water emulsions, are three-phase dispersions composed of inner aqueous droplets dispersed in larger oil droplets, which are themselves dispersed in another aqueous phase. The presence of intermediate (middle) fluid as a protective shell or semi permeable barrier which separates the inner aqueous phase from the outer one, makes double emulsions suitable in a wide range of applications including food, cosmetics, encapsulation of water-soluble therapeutic agents for targetable drug delivery, preparation of biodegradable microcapsules loaded with bioactive polymers, extraction of hydrocarbons, metal ions, and organic acids across a thin liquid layer mediating between the internal drops and the external continuous phase…

Conventional double emulsion production methods such as high-shear homogenizers and colloid mill are based on high shear mixing of immiscible liquids. These devices, however, suffer from poor droplet size reproducibility and are not suitable for generation of core/shell droplets. Recently, microfluidic emulsification devices have attracted much attention due to their unprecedented level of control over droplet size and morphology. In microfluidic devices, droplets can be produced in two main regimes, dripping and jetting, depending on the balance between interfacial, viscous, inertial and gravity forces.

How to generate monodispersed double emulsion

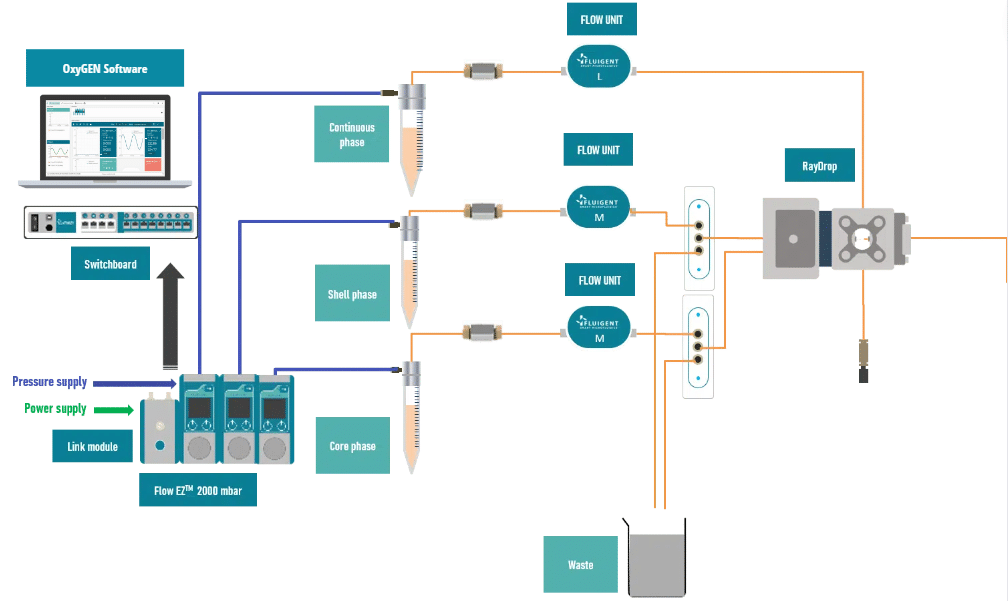

System setup

Get the complete protocol and methods from the application note

Partial results: high monodispersed double emulsion

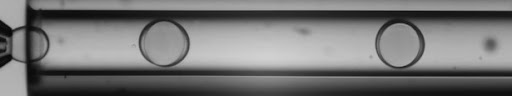

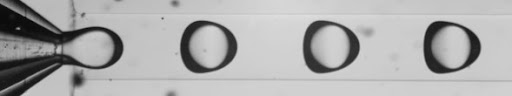

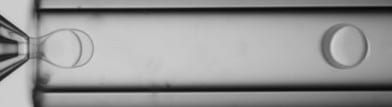

In the experiments, the different flow rates are varied to create either a double emulsion with a large shell or a core-shell double emulsion. The fluid configuration and physical properties, such as viscosity and surface tension, will have a significant impact on the maximum thickness of the shell. Similarly, the fluid configuration will have a significant impact on the production rates that may be achieved.

Water in oil in water double emulsion

Oil in water in oil double emulsion

Partially miscible (solvent) double emulsion

Get the complete results from the application note

Conclusion

In this application note we have demonstrated how we can perform different type of double emulsion generation with a single device.

Precise control of the flow allows also to generate high monodispersity (≈2% size dispersion) double emulsion at different frequencies to target different volume production.

Examples with common fluids such as water, mineral oils, fluorocarbon oils, and solvents have been demonstrated here. This method can also be used for the production of double emulsion with specific fluids such as a polymer (PLGA, PLA,…), hydrogel (Alginate, agarose,…), and others.

As a consequence, this method is a promising method for different markets and could be used in order to get rid of limitations of current technologies such as batch methods and other for different applications such as in pharma, food or cosmetic.

More information

Tutorial on How to Produce Double Emulsion

REPLAY Workshop – Master the double emulsions production

Related Resources

- Microfluidic Application Notes

Alginate Microcapsule Synthesis

Discover - Microfluidic Application Notes

Agarose Microcapsules Synthesis

Discover - Microfluidic Application Notes

PLGA microcapsules synthesis

Discover - Microfluidic Application Notes

Encapsulation of Cells In Small Double Emulsions

Discover - Microfluidics White Papers

Double emulsion for the generation of microcapsules – a Review

Discover - Array

Master the production of Double Emulsions

Discover

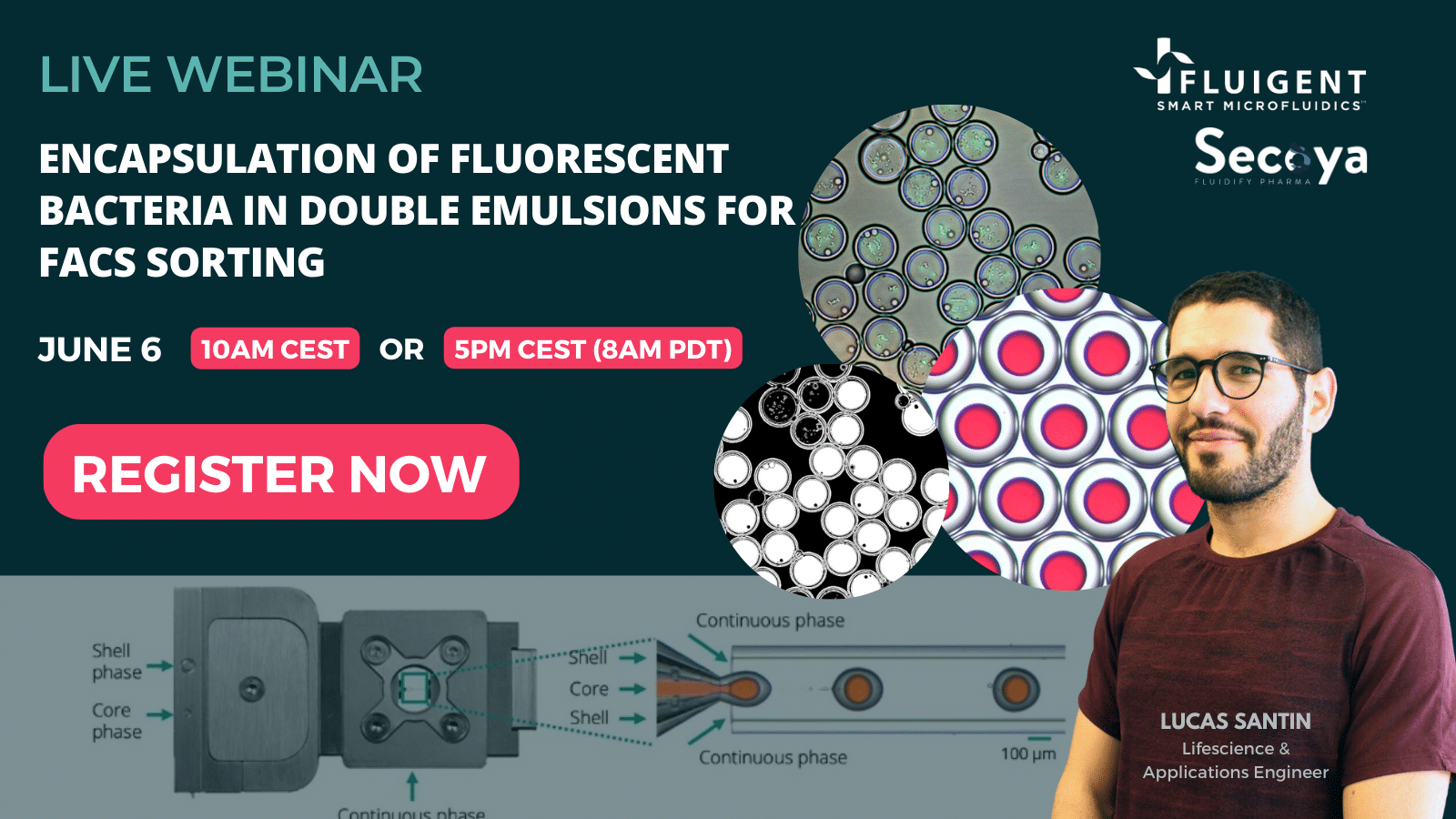

WEBINAR: Encapsulation of fluorescent bacteria in double emulsions for FACS sorting

Discover