Straight forward set & use

Airtight pressurized bottle caps

Bottle-CAP series

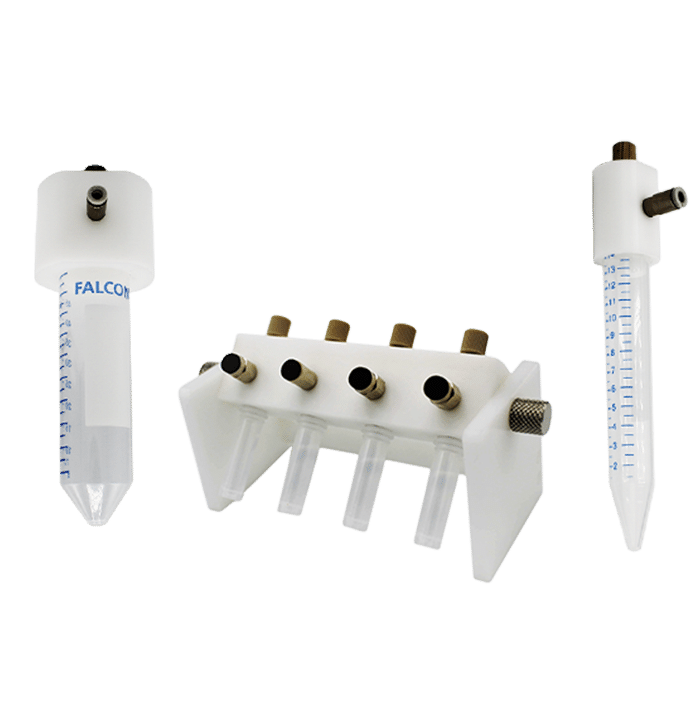

The Bottle-CAP is an airtight microfluidic adapter that allows for pressurization of large volumes of liquid for your microfluidic applications. This cap is compatible with any lab bottle with a standard GL-45 thread. It is compatible with Fluigent pressure controllers from the MFCS™ series and the LineUp™ series. This pressurized bottle cap has 1 fluidic outlet and 1 pneumatic inlet, and the number of outlets for this cap can be customized, with up to 3 fluidic outlets, to refill easily or to perfuse different microfluidic chips at the same time.

Safety warning

Please use caution when working with the pressure control bottle cap. Glass bottles cannot handle pressures over 2 bar. Fluigent strongly advises you to use custom caps with pressures below 2 bar only. If you have questions, please contact Fluigent support at support@fluigent.com.

- Intuitive

- Compatibility

Incubator & Autoclave

- Smart

Refillable during experiment

Features

Pressurize standard lab bottles

The Bottle-CAP is compatible with all standard lab bottles with a GL-45 thread. This allows for handling of large volumes of liquids (>1L), with a refill option to make your experiments last even longer.

Pressure compatibility

The pressurized bottle cap can support pressures up to 2 bar. We strongly recommend that you not exceed this pressure.

Reservoir accessibility

The Bottle-CAP can be heated while handling the fluids, and is compatible with autoclaving and magnetic agitation.

Related applications

What is bottle pressure?

In the context of microfluidics, “bottle pressure” refers to the internal pressure of the bottle. In other words, it is the force exerted by the fluids contained in the bottle.

This pressure can depend on different parameters, including not only the type of fluid but also the temperature and volume inside the bottle.

In microfluidic experiments, it is often useful to regulate this pressure in order to control the flow rate and behavior of the fluid in the setup. This can be done using pressure-based flow controllers from Fluigent, for example, as well as pressure control bottle caps.

The bottle pressure and the pressure exerted by the flow controller are two different things: the bottle pressure refers to the inherent pressure inside the bottle and the pressure exerted by the flow controller is the pressure needed to handle the fluid. The second type of pressure can nevertheless have an influence on the first.

How does pressure work with pressurized bottle caps?

The bottle caps are equipped with two main components: a pressure-based valve and a pressure chamber. The valve allows you to control the fluid and its flow, while the pressure chamber helps to control the pressure.

A pressure-based flow controller allows you to pressurize the bottle by increasing the pressure in the chamber, which then causes the valve to open by the action of a force. The fluid will then be able to flow from the bottle to the external circuit by passing through the pressure control bottle cap. Conversely, by reducing the pressure, the force on the valve decreases, the valve closes and the flow of fluid stops.

Fluigent bottle caps provide a convenient and efficient method for controlling fluid flow in microfluidic setups, offering precise pressure-based regulation to achieve the desired experimental conditions.

Applying pressure with pressure control bottle caps

To apply pressure to a bottle using the bottle cap, you must first ensure that the cap is properly sealing the bottle. Then the cap has to be connected to a pressure-based flow controller like the MFCS or the FlowEZ and to the microfluidic circuit with the appropriate tubing and fittings. The desired pressure is then selected on the pressure controller, corresponding to the pressure applied to the pressure chamber of the pressurized bottle cap. The pressure is then applied to the system, including the cap, which causes its valve to open and allows the fluid contained in the bottle to flow to the rest of the setup. The pressure can be regulated during the experiment by changing it on the pressure controller, or by programming it directly in the software in the case of the LineUp series.

What happens to the pressure when you open the cap?

When the bottle is opened, the pressure inside will equalize with the surrounding atmospheric pressure. The pressures inside and outside the bottle will then be similar and the valve will be closed.

In other words, opening the bottle will break the seal, and the fluid flow will no longer be controlled or regulated by the pressure-based flow controller and the pressure control bottle cap.

Specifications

PERFORMANCE

| Working pressure | from -800 mbar to 2000 mbar (/!\ do not exceed 2 bar) |

HARDWARE SPECIFICATIONS

| Inlet pressure fitting | Luer or 4mm OD |

| Outlet / Inlet fluidic port(s) | 1/4”-28 thread |

| Material | Body: PTFE Seal: Expanded PTFE |

CHEMICAL COMPATIBILITY

| Gas compatibility | Dry, oil-free gas, air, any non corrosive or non explosive gas |

| Liquid compatibility | Aqueous solvent, oil, organic solent, biological sample |