Multiply the outputs

Pneumatic Valve Controller

[ELUPSW2000]P-SWITCH

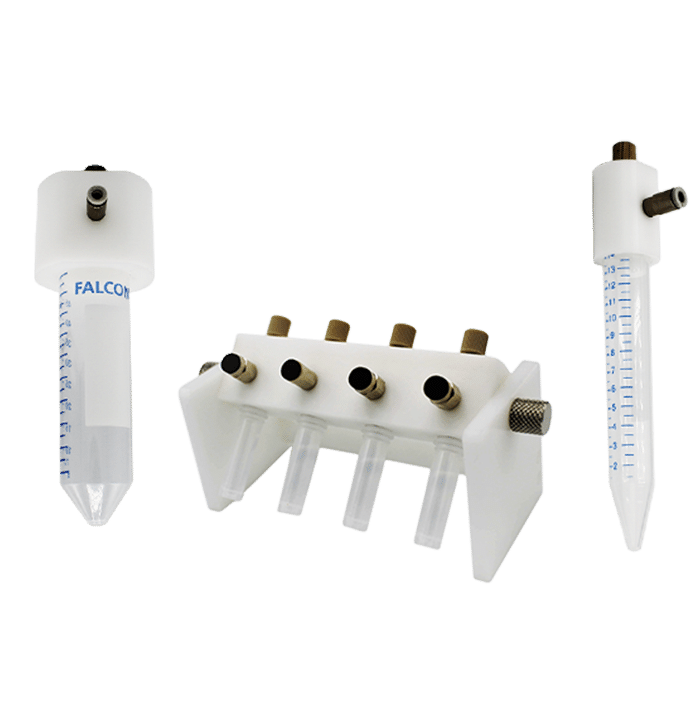

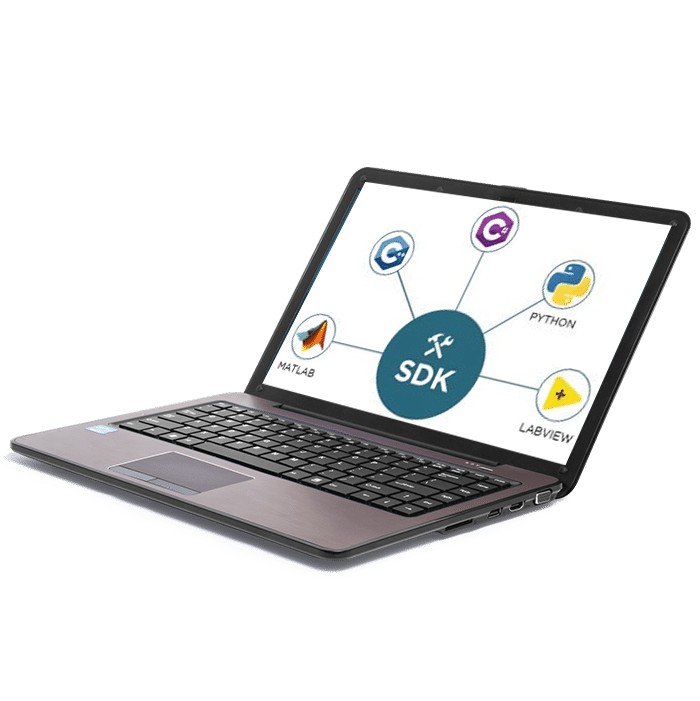

The LineUp™ P-SWITCH is a pneumatic valve controller. By providing two pressure sources (any vacuum or pressure from -800 to +2000 mbar), each module can deliver one of the two provided pressures through 8 independent outlets. The module can be used to multiply the channel output number in the LineUp™ system or any other pressure system.Similar to every other LineUp series module, the P-SWITCH microlfuidic valve can be controlled manually, locally and remotely, using FLUIGENT dedicated software solutions or custom applications. This can be done through LabView, Python, Matlab, C++ or any other development environment of your choice.

- Multiple

- Compact

Uses minimum bench space

- Adaptable

Use with or without a PC

- Intuitive

Straight forward set up & use

Features of P-SWITCH pneumatic valve controller

Expand as needed

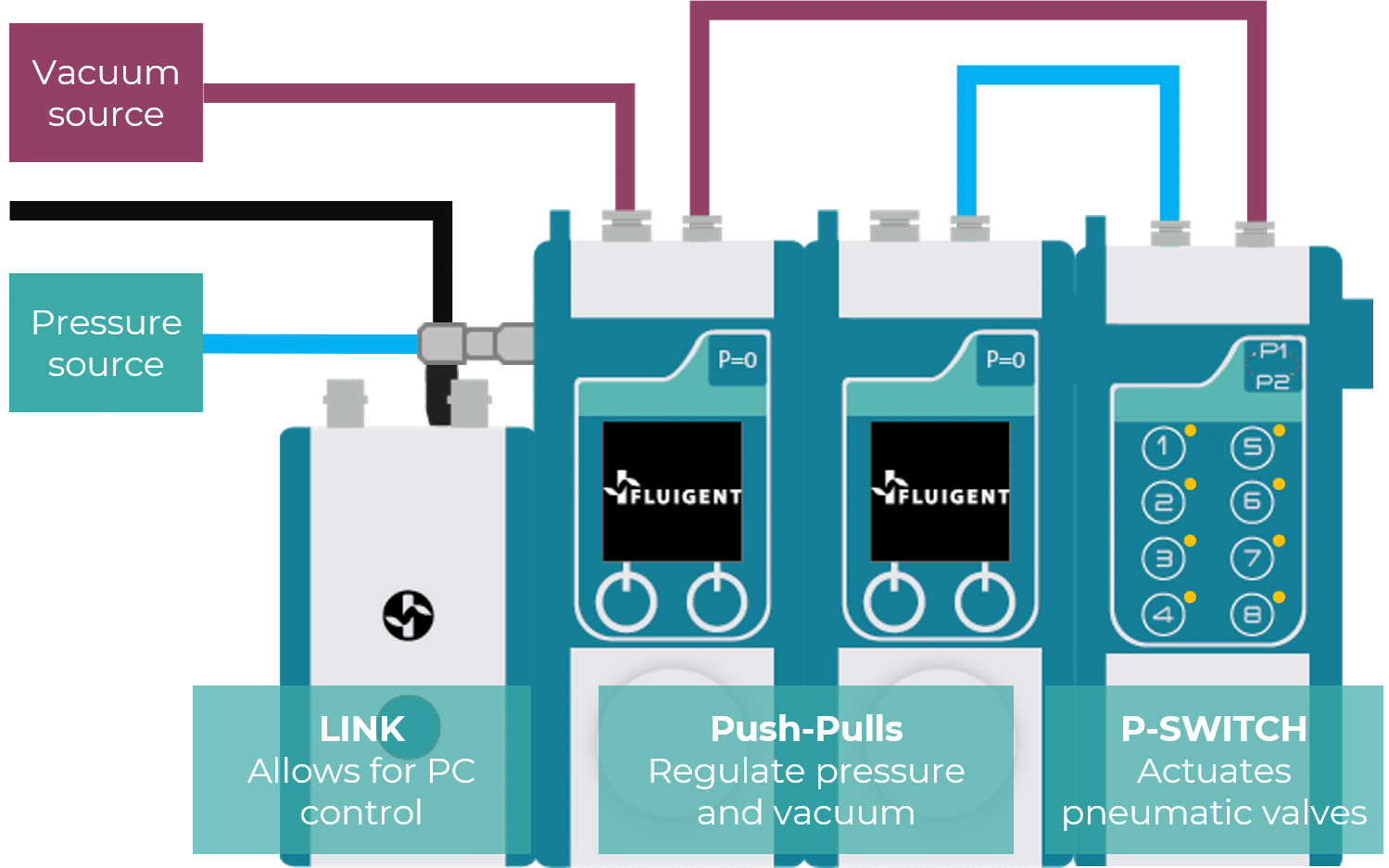

The LineUp™ series module can be combined to add pressure/vacuum channels, valve control and turn one channel into 8 independent outlets using the pneumatic valve controller. Expand your system up to 32 outlets with 4 modules.

Pressure & vacuum compatibility

Each P-SWITCH module requires 2 supplied sources over the range of -800 mbar to 2 bar. Combined with Flow EZ™ and Push-Pull, set a versatile system for pressure-base microfluidic experiments.

Local control

Control and regulate pressure and flow rate without a PC using the LineUp™ hardware interface. Use the P-SWITCH buttons to quickly commute outlets between the two supplied pressure(s)/vacuum(s) and focus on the experiment.

Parallelize reservoirs

Connect the outlets of the P-SWITCH microfluidic valve to independent reservoirs to perform independent injections. Pressurize up to 32 reservoirs simultaneously or independently.

Actuate pneumatic valve

Connect the outlets of the pneumatic valve controller directly to quake or on-chip pneumatic valves to actuate them. Control and handle the fluid on the chip without additional tubing.

Advantages of Fluigent’s Pneumatic Valve Control System

- Quick changing of liquids

- Less dead/internal volumes (compared to fluidic valves)

- No liquid contact with the instrument

- Less cross-contamination (compared to fluidic valves)

- Possibility to inject one or several solutions at the same time

- Expandable for multiple pneumatic controls

How to easily control pneumatic valves

P-SWITCH is a microfluidic valve that will simplify your experiments. It allows for the pressurizing of multiple reservoirs at once or actuating various types of pneumatic valves in a microfluidic set-up.

The versatility of the pneumatic valve controller comes from the fact that it can be used in combination with other LineUp modules-such as the Push-Pull or Flow EZ– to provide regulated pressure as a complete and compact system, or independently as a standalone tool.

Part of our LineUp Series

Pressure and vacuum control, flow rate control, microfluidic valve automation, and software control. Select and combine the modules you need from our range of LineUp™ products. Our devices have become the gold standard for microfluidic flow control over the years.

Focus on the microscope. No PC is required

Instead of looking at the PC, users can keep their eyes on the microscope, adjusting the control dial with one hand. In this stand-alone configuration, the device allows for pressure or flow rate control and volume dispense making it ideal for benchtop use.

Specifications

What is a pneumatic valve?

A pneumatic valve used in microfluidics is a valve that is actuated by compressed air to control the flow of fluids like oil or water in microchannels. Due to their ease of control, low power requirements, and compatibility with other pneumatic components like pumps and sensors, pneumatic valves are a popular choice for microfluidic applications. Fluigent valves, for instance, can be easily integrated into setups and controlled in real-time without the need for a PC, allowing users to complexify the fluidic path of any experiment.

The flexible membrane or diaphragm of a pneumatic valve is typically made of an elastomer or polymer that can be deflected by applying pressure from an external source like an RX pressure source. This deflection opens or closes the microchannel, thereby controlling fluid flow.

Overall, pneumatic valves offer a versatile and reliable option for precise control of fluid flow in microfluidics. They are commonly used in various fields, including research laboratories, medical diagnostics, and chemical synthesis, due to their minimized reagent consumption, low internal volume, and prevention of cross-contamination and biofilm formation, which help avoid dead volumes.

What are some common applications of microfluidic valve controllers?

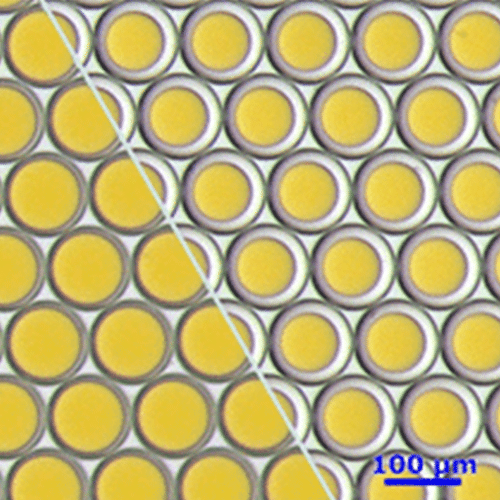

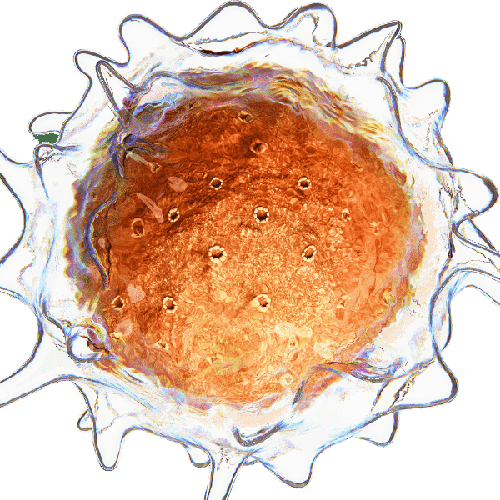

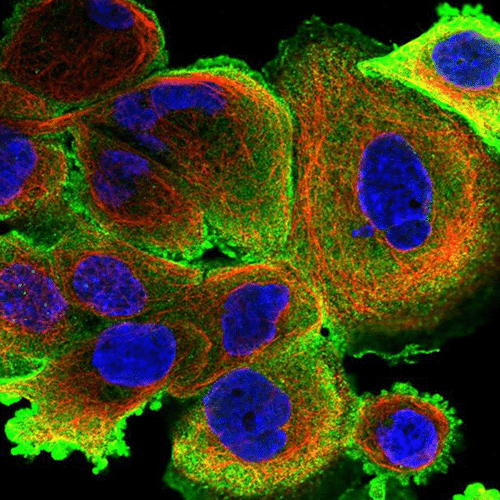

A pneumatic valve controller is a crucial tool in microfluidics research, allowing for precise control of fluid flow in microchannels. It can be used in lab-on-a-chip devices, cell culture applications, microdroplet generation and organ-on-a-chip devices. These controllers enable the precise control of fluid flow, nutrients, oxygen, and the generation of microdroplets, which have various applications such as drug delivery, diagnostic assays, chemical synthesis, drug testing, and disease modeling. They play a critical role in enabling the development of innovative microfluidic devices for various fields, including biomedicine, chemistry, and engineering.

How to use the P-Switch in a microfluidic setup

The P-Switch, a pneumatic valve control system, can be integrated into a microfluidic system by connecting it to a pressure or vacuum source using tubings (able to handle positive pressure up to 2000 mbar and vacuum down to -800 mbar) .Each inlet can be connected a microfluidic path, for instance to a reservoir. It can be used alone or with other LineUP modules that can be connected together. Valves can be switched directly on the module or via the software that enables the automation of protocols and programming of pressure sequences. Finally, up to 32 different outlets can be achieved by combining the P-Switch module with three others. Start your experiment using this module and explore its potential for microfluidic applications.

PERFORMANCE

| Valve actuation timing | 10 ms |

| Response time | Down to 30 ms |

HARDWARE SPECIFICATIONS

| Dimensions | 91,9 x 71,8 x 131 mm |

| Weight | 428 g |

ELECTRONICAL SPECIFICATIONS

| Power consumption | 6 W |

CHEMICAL COMPATIBILITY

| Gas compatibility | Dry, oil-free gas, air, any non corrosive or non explosive gas |

| Liquid compatibility | Aqueous solvent, oil, organic solent, biological sample |

OxyGEN

| Control in real-time, protocol automation, data record and export |

| ver. 2.2.0.0 or more recent |

Software Development Kit

| Custom software application |

| ver. 22.2.0.0 or more recent |

Expertise & resources

-

Expert Reviews: Basics of Microfluidics Microfluidic Flow Sensing Technologies, A Review Read more

-

Microfluidics White Papers Microfluidic white paper – A review of Organ on Chip Technology Read more

-

Microfluidics White Papers Droplet-based Microfluidics Read more

-

Fluigent products manual P-SWITCH User Manual Download

-

Fluigent Products Datasheets P-SWITCH Datasheet Download

Related products

Microfluidic Push Pull controller

Regulate negative and positive pressure

See the offer

Microfluidic flow controller

Flow EZ™

See the offer

Microfluidic Software Control

Microfluidic Software control

See the offer

Microfluidic valve controller for flow redirection

SWITCH EZ

See the offer

Lab Integration Software

Custom software development SDK

See the offer