Straight forward set up & use

Microfluidic flow controller

[LU-FEZ]- Best Seller

- Made in France

Flow EZ™

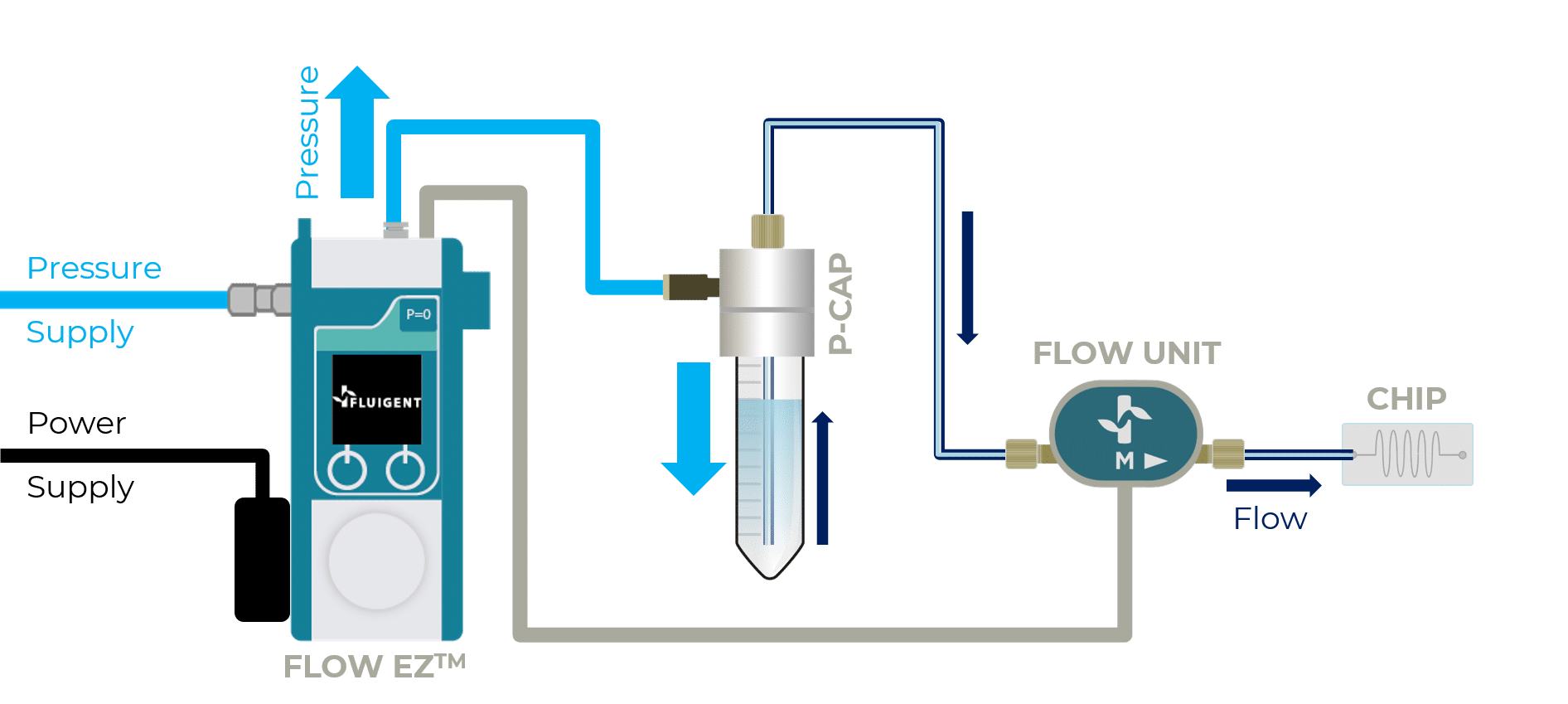

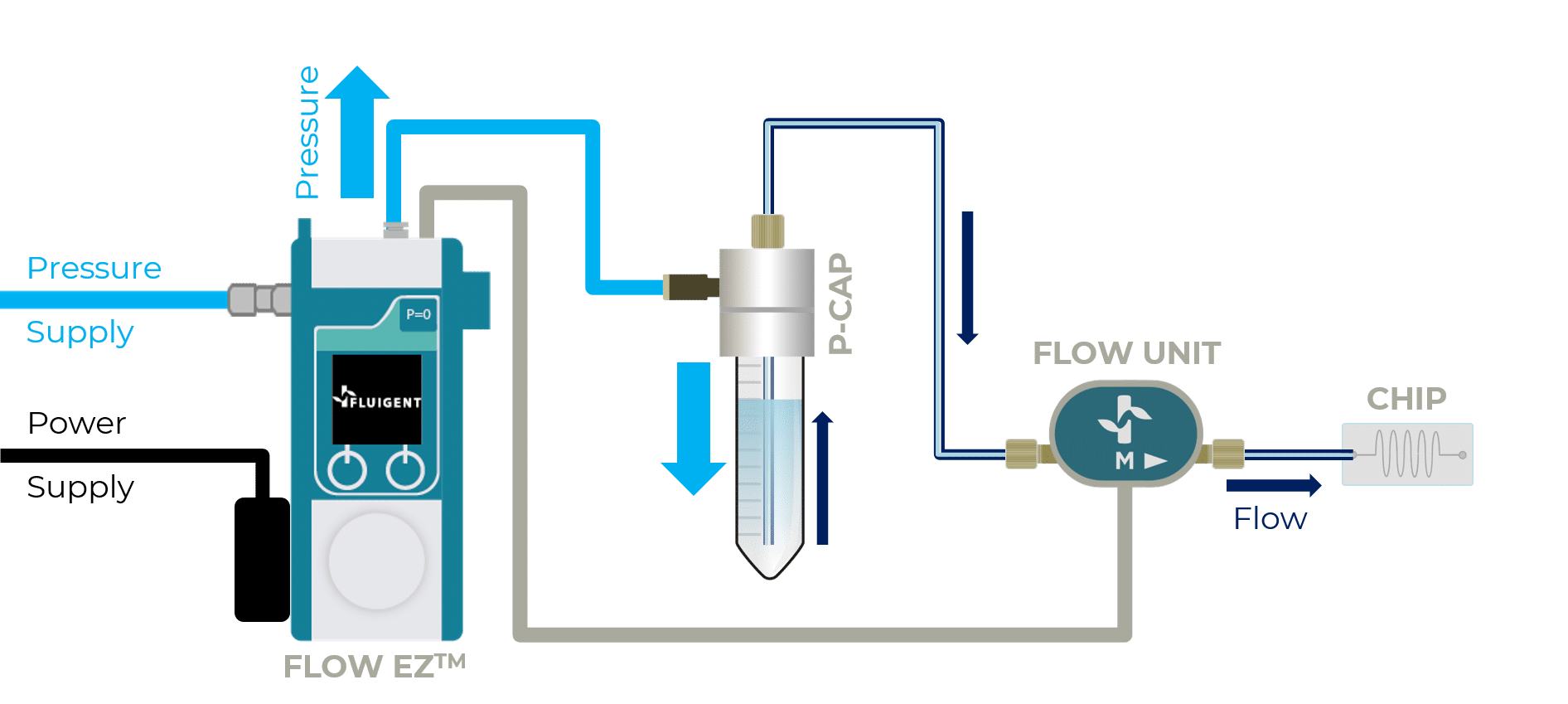

The Flow EZ™ is the most advanced system available for pressure-based flow control. The compact flow controller stands near the microfluidic device, allowing the user to minimize bench space use without the need of a PC.

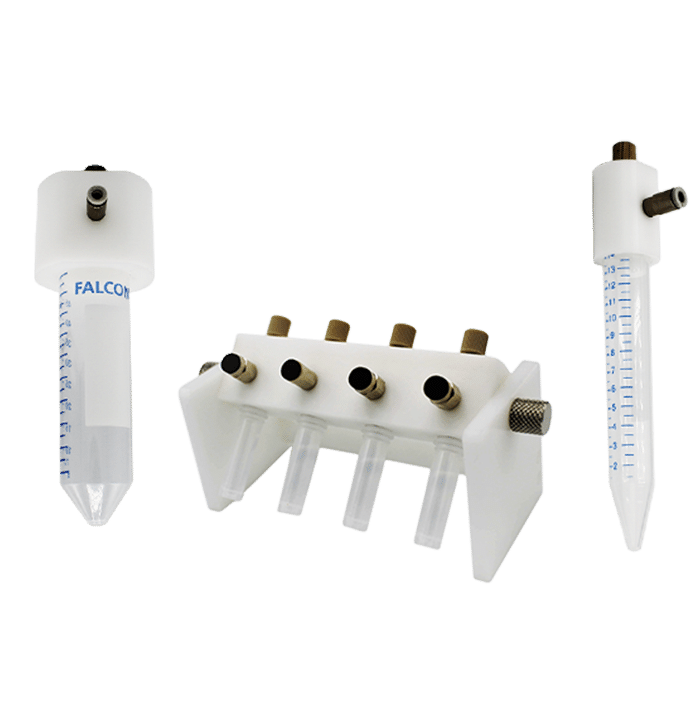

One can be operational and generate data rapidly. The microfluidic flow controller supports reservoir sizes from 2 mL to one liter laboratory bottles. One can use large reservoirs and maintain continuous, pulseless flow for days without refilling.

- Intuitive

- Adaptable

Use with or without a PC

- Modular

Expand the system as needed

- Compact

Uses minimum bench space

Features of our compact flow controller

Expand as needed

Combine up to 8 modules as your work flow grows. Each microfluidic flow regulator is a separate and independant pressure channel.

Pressure and vacuum control

The Flow EZ™ range of modules allow for regulation of pressure / vacuum down to -800 mbar and up to 7 bar.

Local control

Control without a PC using the Flow EZ™ hardware interface with one hand. Focus on the experiment instead of looking at the PC.

Precise volume delivery

When combined with a FLOW UNIT, one can control flow rate directly or deliver dispensed volumes as needed.

Various reservoir sizes

Support reservoir sizes from 2 mL to one liter laboratory bottles. The Flow EZ™ can maintain continuous, pulseless flow for days without refilling.

Highlights

The Flow EZTM, a state-of-the-art microfluidic flow controller

Based on our industry leading experience, Fluigent has developed the patented pneumatic system: the most advanced microfluidic pumping technology available. It is at the heart of the Fluigent’s next generation performance providing the fastest, most stable, and compact microfluidic system In the base configuration, the system controls the pressure or vacuum, and the liquid flow is a function of system resistance, fluid viscosity, etc. The addition of a FLOW UNIT enables one to control or monitor flow rate as well as measure a dispensed volume. The pressure automatically adjusts in the background to maintain the set flow rate.

When combined with the LINK module, the Flow EZ™ flow controller’s capabilities are extended by using Fluigent software to control the system or to generate time based protocols and record data (OxyGEN software).

The Flow EZ™ microfluidic flow controller modules are available in different pressure and vacuum ranges to provide the optimum level of pressure control and resolution. These can easily be combined to match all application requirements or reconfigure the system for a new experimental design.

“We are really happy with Flugent microfluidics control systems: they are very EZ to use; they are also robust and reliable. We want to highlight in particular the user-friendliness of the software (OxyGEN), and the ease with which one can implement their own third-party programs to embed Fluigent controllers to a bigger setup comprising multiple units from different manufacturers.”

Prof. Artem Mishchenko – Université de Manchester

Discover the most advanced microfluidic flow regulator

With a compact and modular design, this microfluidic flow controller allows you to set and benefit quickly from the pressure-based flow control advantages for your experiments.

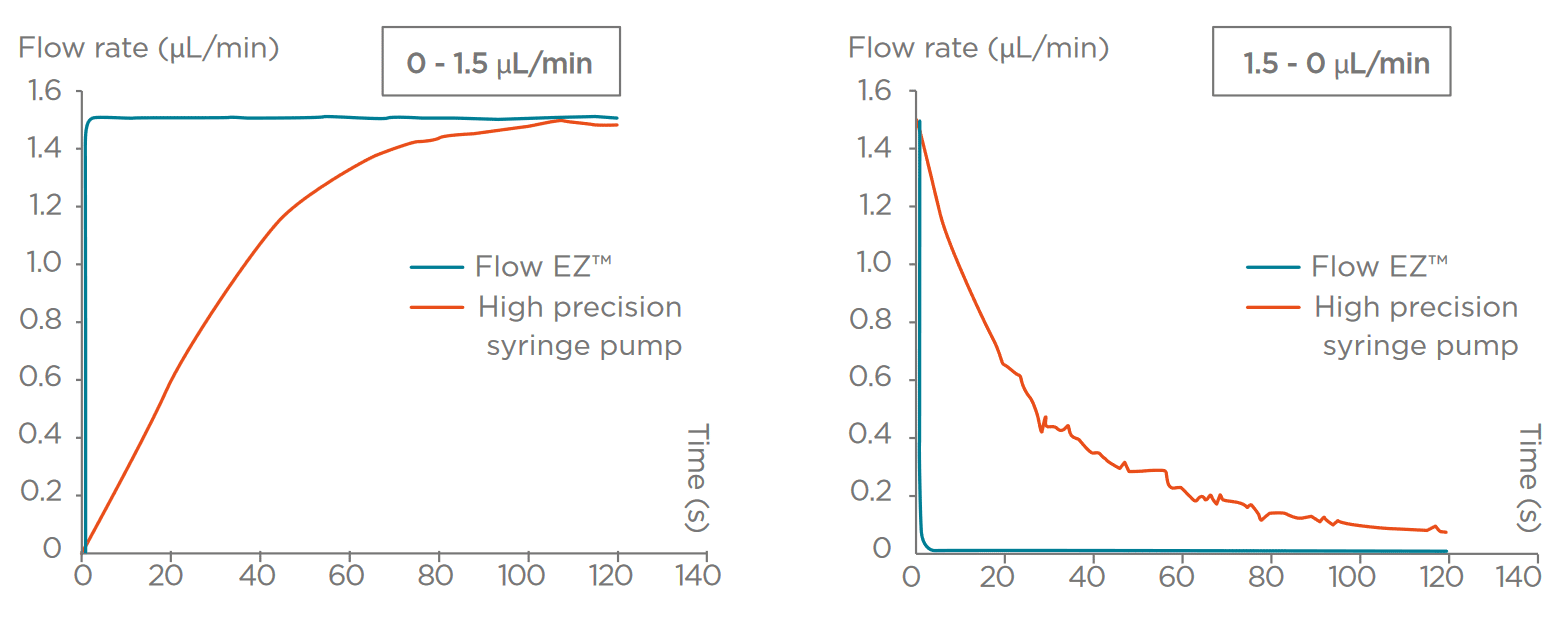

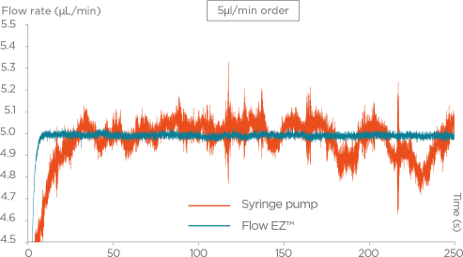

A response time ten times faster compared to syringe pumps.

With the use of pressure instead of mechanical action, the Flow EZTM microfluidic flow controller gets a responsiveness ten times faster than syringe pumps. A low response time allows users to quickly execute operations such as stop flow and pressure/flow rate steps.

Control flow rate with the benefits of responsive, pulse-free flow

Pulse-free flow is critical for generating high quality and repeatable results. The Microfluidic flow controller integrates the all-new DFC (Direct Flow Control) algorithm. This allows users to set a flow rate directly on the instrument display. The applied pressure will automatically adjust to maintain the flow rate.

“We came to Fluigent when we were building an automated microfluidic platform for screening chemical reactions. Fluigent products are powerful in precise control of the flow conditions and can guarantee the performance of our platform. The pump system is user-friendly and can be extended to complex experimental systems where multiple pumps are needed. The above merits have made our experimental design process smooth and easy.”

Dr. Huizhi Wang- Imperial College London

Part of our LineUp Series

Pressure and vacuum control, flow rate control, microfluidic valve automation, and software control. Select and combine the modules you need from our range of LineUp™ products. Our devices have become the gold standard for microfluidic flow control over the years.

Webinar- Flow Control in Microfluidics

Discover the performance, advantages of limitations of common flow controllers, including pressure pumps.

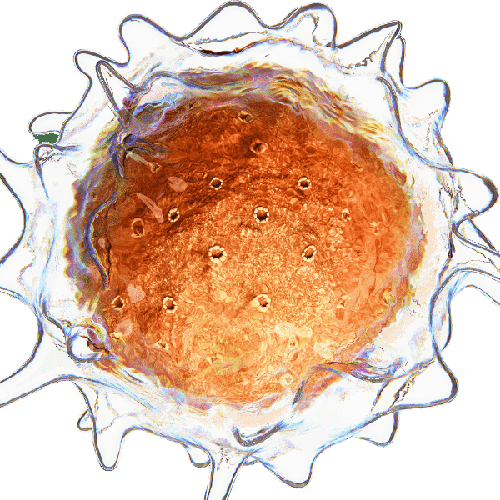

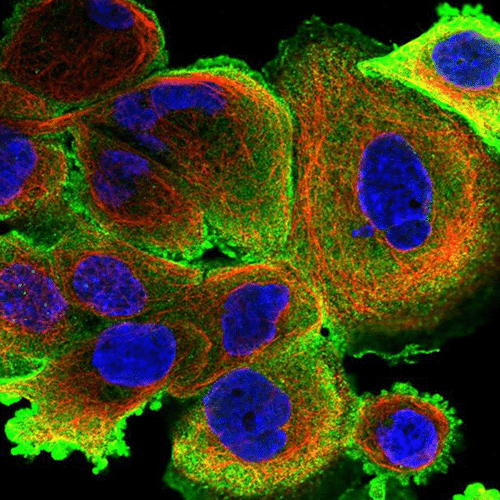

In this session, Dr. Alexandre Grassart will present his groundbreaking research on mechanobiology using a gut-on-chip model, and will highlight how mastering flow control allowed to improve his organ-on-a-chip research.

“We connect the chips to the Fluigent pump system because that allows us to deliver more complex flow environments […] and visualize live on the microscope.”

Martin Knight | Professor of mechanobiology at Queen Mary university of London

Focus on the microscope. No PC required

Instead of looking at the PC, users can keep their eyes on the microscope, adjusting the control dial with one hand. In this stand-alone configuration, the device allows for pressure or flow rate control and volume dispense, making it ideal for benchtop use.

“The Fluigent microfluidics flow system has allowed us to expand our static cell models into a model of cells under flow that represents in vivo conditions more closely. Through this addition, we have been able to increase our publication output, with microfluidics at the heart of this research.

The FlowEZ allows us to manipulate flow rates quickly that allows us to introduce various activators and inhibitors to our cells, and create a system of recirculation that minimizes volume requirements, sample loss, and removes the need for users to be present for the experiment to run for hours at a time.”

Dr Cass Whelan | Research Associate, Cardiff Metropolitan University – UK

Specifications

PERFORMANCE

| Resolution | 0,03% full scale |

| Stability | 0,1% on the measured value (effective beyond 10% of the maximum pressure) |

| Accuracy | 0,25% full scale |

| Repeatability | <0.01% full scale |

| Response time | Down to 30 ms |

PRESSURE/VACUUM RANGE

| Part number | Pressure/Vacuum range | Required supply | Maximum pressure supply |

| LU-FEZ-0025 | 0 to 25 mbar (0 to 0,36 psi) | 150 mbar (0,22 psi) | 300 mbar (4.35 psi) |

| LU-FEZ-0069 | 0 to 69 mbar (0 to 1,0 psi) | 150 mbar (0,22 psi) | 300 mbar (4.35 psi) |

| LU-FEZ-0345 | 0 to 345 mbar (0 to 5,00 psi) | 1100 mbar (15,95 psi) | 1300 mbar (18.85 psi) |

| LU-FEZ-1000 | 0 to 1000 mbar (0 to 14,50 psi) | 1100 mbar (15,95 psi) | 1400 mbar (20.3 psi) |

| LU-FEZ-2000 | 0 to 2000 mbar (0 to 29,01 psi) | 2100 mbar (30,46 psi) | 2600 mbar (37.7 psi) |

| LU-FEZ-7000 | 0 to 7000 mbar (0 to 101,5 psi) | 7100 mbar (103,0 psi) | 7400 mbar (107.32 psi) |

| LU-FEZ-N025 | 0 to -25 mbar (0 to -0,36 psi) | -800 mbar (-11,6 psi) | N/A |

| LU-FEZ-N069 | 0 to -69 mbar (0 to -1,0 psi) | -800 mbar (-11,6 psi) | N/A |

| LU-FEZ-N345 | 0 to -345 mbar (0 to -5,00 psi) | -800 mbar (-11,6 psi) | N/A |

| LU-FEZ-N800 | 0 to -800 mbar (0 to -11,6 psi) | -800 mbar (-11,6 psi) | N/A |

STANDARD OPERATING CONDITIONS

| Operating temperature | 20°C (68°F) |

| Operating humidity | 40% HR |

HARDWARE SPECIFICATIONS

| Dimensions | 91,9 x 71,8 x 131 mm (3.6 x 2.8 x 5.15 in) |

| Weight | 634 g (1.4 lbs) |

ELECTRONICAL SPECIFICATIONS

| Power consumption | 6 W |

CHEMICAL COMPATIBILITY

| Gas compatibility | Dry, oil-free gas, air, any non corrosive or non explosive gas |

| Liquid compatibility | Aqueous solvent, oil, organic solent, biological sample |

OxyGEN

| Control in real-time, protocol automation, data record and export |

| ver. 2.2.0.0 or more recent |

Software Development Kit

| Custom software application |

| ver. 22.2.0.0 or more recent |

Firmware updater

FAQ

How to determine the pressure range to choose?

Fluigent has developed a flow rate calculator to assist users in selecting the appropriate pressure range and microfluidic flow controller for their microfluidic system. They just have to provide details about their setup, including chip geometry, control type, channel and tubing dimensions. generate recommendations for flow rates and pressure ranges based on the provided data.

How can I directly control the flow rate?

Fluigent’s Flow Ez technology operates by controlling fluid flow through pressure monitoring, but the company also offers a solution for flow rate monitoring. The Flow Unit is a one-of-a-kind microfluidic flow sensor that accurately and easily monitors flow rates in any microfluidic system. An advanced thermal sensor technology provides complete media isolation and an extremely low internal volume, with no moving parts. Flow rate is then calculated based on thermal desorption, which is directly correlated with flow rate. This bidirectional microfluidic flow sensor can be used in conjunction with a microfluidic flow controller, such as the Flow Ez. To put in a nutshell, the Flow Unit is capable of measuring ultra-low liquid flow rates quickly and with exceptional precision.

Is a pressure/vacuum source needed in my setup?

The Line Up flow controllers are not equipped with an internal pressure or vacuum source, but are instead compatible with laboratory-built sources or portable pressure/vacuum generators. Fluigent provides a variety of compact pressure sources, including the Fluigent RX and FLPG Plus models, as well as a compact vacuum source. These user-friendly solutions are suitable for any flow rate and application.

How to program my experiment?

While this microfluidic flow regulator can be used independently, users also have the option of utilizing the OxyGEN software to control various parameters by simply plugging it into any computer. This software allows for real-time monitoring and automation of experiments, enabling users to create or modify time-based protocols with a variety of dedicated functions. These functions range from simple flow rate control to more complex features like conditional paths or looping. By utilizing the OxyGEN software with microfluidic flow controller and automating their experiments, users can improve the reliability and reproducibility of their results.

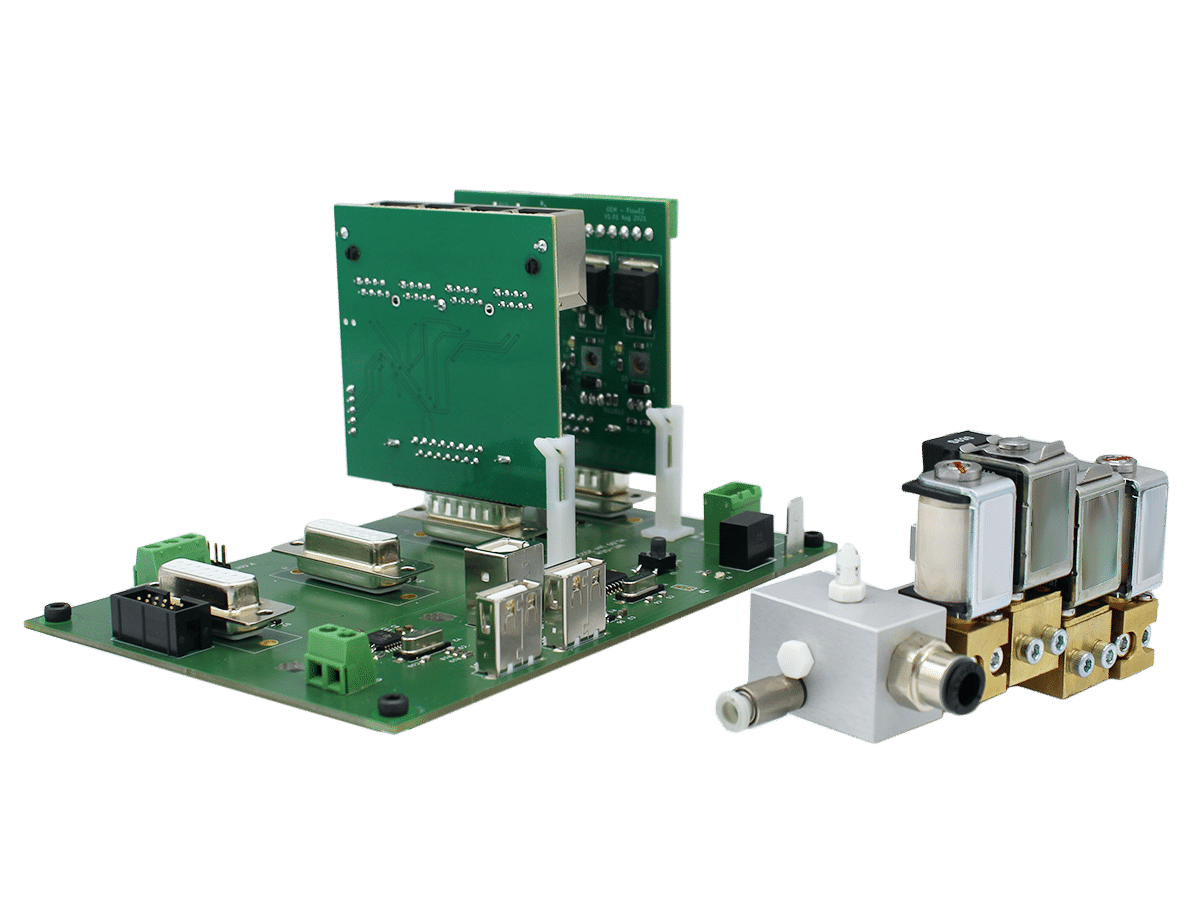

OEM device available

Whether you prefer to use the Flow EZ on a laboratory bench or integrate it into your own product, Fluigent has the perfect solution for your industrial development needs. Let us introduce you our F-OEM modular microfluidics flow Controller !

Expertise & resources

-

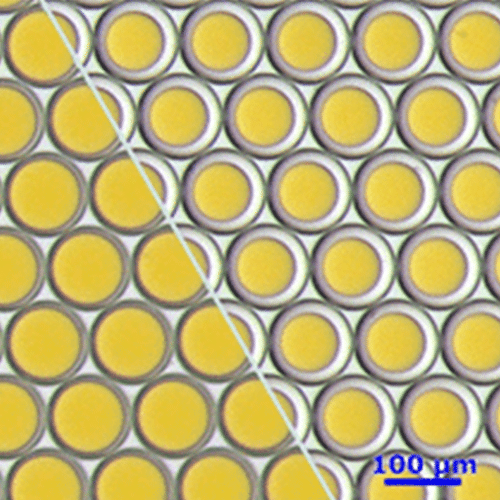

Microfluidics White Papers Double emulsion for the generation of microcapsules – a Review Read more

-

Tutorial videos Flow EZ Tutorials Episode 8: Switch it off – Fluigent Read more

-

Tutorial videos Flow EZ Tutorials Episode 7: Use the P=0 button – Fluigent Read more

-

Tutorial videos Flow EZ Tutorials Episode 6: Add my FLOW UNIT – Fluigent Read more

-

Tutorial videos Flow EZ Tutorials Episode 5: Disconnect a Flow EZ – Fluigent Read more

-

Tutorial videos Flow EZ Tutorials Episode 4 : Apply a pressure order – Fluigent Read more

-

Tutorial videos Flow EZ Tutorials Episode 3 : Add a Flow EZ – Fluigent Read more

-

Tutorial videos Flow EZ Tutorial Episode 2 : Insert in my setup – Fluigent Read more

-

Tutorial videos Flow EZ Tutorial Episode 1 : Getting started – Fluigent Read more

-

Microfluidic Application Notes Encapsulation of multiple emulsions in a single droplet Read more

-

Microfluidics Article Reviews Human Blood Brain Barrier (BBB) permeability -on-chip assessment Read more

-

Expert Reviews: Basics of Microfluidics Choosing the Right Microfluidic Pressure Range Read more

-

Fluigent Media Kit product icons & images Fluigent product icons & images Read more

-

Microfluidics White Papers An exploration of Microfluidic technology and fluid handling Read more

-

Microfluidics case studies The Hebrew University: Encapsulation and culture in 3D hydrogels for Single cell sequencing Read more

-

Microfluidics case studies University of Cambridge: Microfluidic GUV production and testing Read more

-

Microfluidics case studies CEA/CNRS: A flow cell for nanoscopic imaging in liquid Read more

-

Microfluidics case studies The Micro/Nano Bioelectronics and Biosensors (MBIOS) from Tianjin University Read more

-

Microfluidic Application Notes Peristaltic Pump vs Pressure-Based Microfluidic Flow Control for Organ on Chip applications Read more

-

Microfluidic Application Notes Double Emulsion Generation Read more

-

Microfluidic Application Notes Microfluidic Chitosan Microcapsules Production Read more

-

Microfluidic Application Notes Liposome Nanoparticle Synthesis Read more

-

Microfluidic Application Notes E. Coli Culture in Droplets Using dSURF Fluorosurfactant Read more

-

Microfluidic Application Notes Microfluidics for Transmission Electron Microscopy: Characterization of Copper Electrodeposition Read more

-

Microfluidic Application Notes Generating a water emulsion in an oil solution using a droplet generator chip Read more

-

Expert Reviews: Basics of Microfluidics Prostate Organoid Culture in Microbeads Read more

-

Microfluidic Application Notes Oil in Water Emulsions Read more

-

Microfluidic Application Notes Impedance Measurement of Microbeads Read more

-

Expert Reviews: Basics of Microfluidics Flow control for droplet generation using syringe pumps and pressure-based flow controllers Read more

-

Expert Reviews: Basics of Microfluidics Microfluidic Flow Control: Comparison between peristaltic, syringe and pressure pumps for microfluidic applications Read more

-

Fluigent products manual LineUp™ series User Manual Download

-

Fluigent Products Datasheets Flow EZ™ Datasheet Download

-

Microfluidics case studies University of Maryland: Microfluidic System for Robotic that can Play Nintendo Read more

Related products

Microfluidic Push Pull controller

Regulate negative and positive pressure

See the offer

Bidirectional Microfluidic Flow Sensor

FLOW UNIT | FLOW UNIT +

See the offer

Microfluidic Software Control

Microfluidic Software control

See the offer

Pneumatic Valve Controller

P-SWITCH

See the offer

Compact Vacuum Pump

VACUUM SOURCE

See the offer