Uses minimum bench space

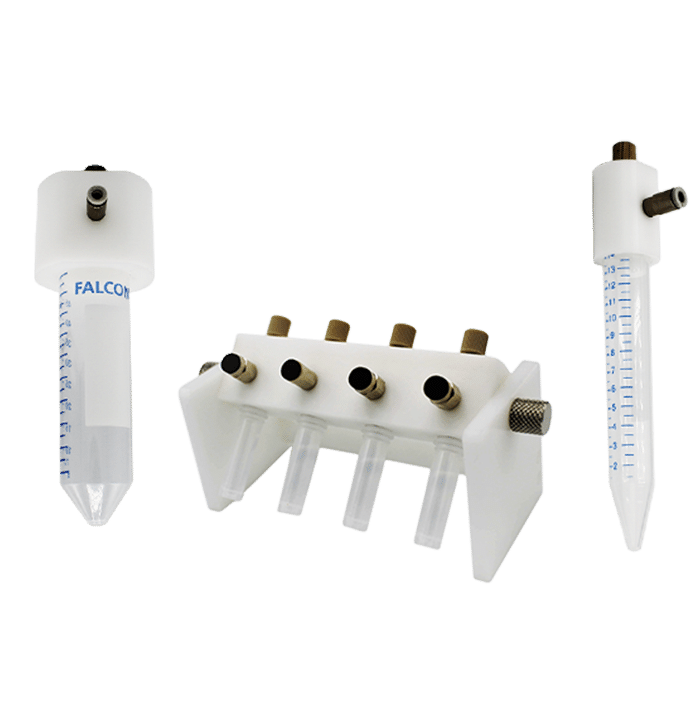

Bubble Trap

[CTQ-006BT]Air Bubbles Remover

Remove air bubbles from your system

The microfluidic Bubble Trap from Fluigent is a device suitable for aqueous flows, perfectly designed to prevent air bubbles from entering a microfluidic system. By employing a nano-porous membrane within the trap and operating in a bubble-free microfluidic environment, it effectively prevents high flowrate instabilities, significant shear stress variations, and potential damage to the microfluidic system.

- Compact

- Intuitive

Standard and easy connection

Why and how to use a microfluidic bubble trap

A microfluidic bubble trap is a device that is used to separate air bubbles from a liquid flow in microfluidic systems. Bubbles are generally undesirable in microfluidics, as even the smallest of them can completely ruin a biological or chemical experiment. They can damage cell membranes, disrupt droplet generation, block channels, prevent current conduction in a capillary, or sweep biological and chemical agents away. Bubbles can come from an inhomogeneous solution or from the presence of fluidic components with dead volumes, randomly getting in the fluidic path. Therefore, it is essential to remove these bubbles before they cause any damage, and adding a bubble remover to your microfluidic setup may be necessary to avoid endlessly repeating an experiment due to bubble-related damage.

There are various ways to use a bubble remover, but the most common method involves using a hydrophobic micro-porous membrane (PTFE) that the liquid and air bubbles flow through. The hydrophobic surface repels the liquid, causing it to flow around the bubble and allowing the bubble to move freely towards the trap. The trap consists of a narrow channel where the bubble gets trapped and diverted to an area where it can be removed from the system. The narrow channel’s design ensures that the bubble is trapped, and the liquid can flow freely without any interference from the air bubble.

To use a debubbler, you need to ensure that it is properly integrated into your microfluidic system. This involves connecting the trap’s inlet and outlet channels to the main microfluidic channels, allowing the liquid to flow through the trap. It is important to note that the device’s efficiency depends on various factors such as the flow rate, the viscosity of the liquid, and the size of the air bubbles. Therefore, it is crucial to optimize these parameters for best results.

Using a microfluidic debubbler in your Fluigent setup

To prevent the formation of bubbles in your microfluidic setup, certain steps are essential. Firstly, it’s important to ensure that your fluid is free of any bubbles from the outset. This initial bubble-free state will minimize the potential entry of air into the system. The second step involves using a bubble remover, which consists of two fluid ports and one gas exhaust. The first port serves as an inlet for the fluid, while the second port functions as an outlet. By passing the liquid through this device, any remaining bubbles should be effectively removed.

To include the bubble trap in a microfluidic setup, the user simply needs to connect the inlet port of the trap to the part of the fluid system where bubbles are likely to be present. The outlet port should be connected to the desired setup destination, such as a microfluidic chip. Either 1/16 or 1/32 OD tubing and standard 1/4″-28 fittings can be used for this purpose, and the flow rate through the bubble remover can reach up to 5mL/min. After using the equipment, it is advisable to flush the unit with de-ionized or distilled water to prevent the formation of salt crystals. This practice helps to prolong the lifespan of the trap.

However, there are some important considerations to keep in mind. The debubbler cannot be autoclaved, and is suitable only for aqueous flows. Using organic liquids may result in leakage. Additionally, the bubble trap should not be used in withdrawal mode as it may generate bubbles. It is crucial to always push the liquid towards the trap to ensure proper functionality.

Specifications

| Material | PVC/PTFE |

| Maximum pressure | Up to 2 bar |

| Maximum flow rate | Up to 5 mL/min |

| Connection | 1/4-28 flangeless fittings |

| Weight | 450 g |

- This item is not autoclavable

- This item should not be used with organic solvent

- The membrane lifetime depends on the kind of fluids being used

Expertise & resources

-

Microfluidics case studies University of Rochester: A tissue chip platform for real-time sensing of secreted inflammatory markers using ARIA Read more

-

Microfluidics White Papers Droplet-based Microfluidics Read more

-

Microfluidics White Papers An exploration of Microfluidic technology and fluid handling Read more

Related products

Microfluidic Push Pull controller

Regulate negative and positive pressure

See the offer

Microfluidic flow controller

Flow EZ™

See the offer

Bidirectional Microfluidic Flow Sensor

FLOW UNIT | FLOW UNIT +

See the offer

Microfluidic Single Emulsion Device

RayDrop Single Emulsion

See the offer

Microfluidic Double Emulsion Device

RayDrop Double Emulsion

See the offer