Microfluidics for Droplet Generation

The science of flow control for emulsion and particle production

- High monodispersity

- High control

- High encapsulation efficiency

- Avoid loss of expensive reagents

What can droplet microfluidics be used for?

Drug delivery

In recent years, biodegradable microcapsules/microparticles have gained widespread importance in the delivery of bioactive agents. Polymer-based microcapsules/microparticles are one of the most successful new drug delivery systems.

They can be used in various areas such as long-term release systems, vaccine adjuvant, and tissue engineering.

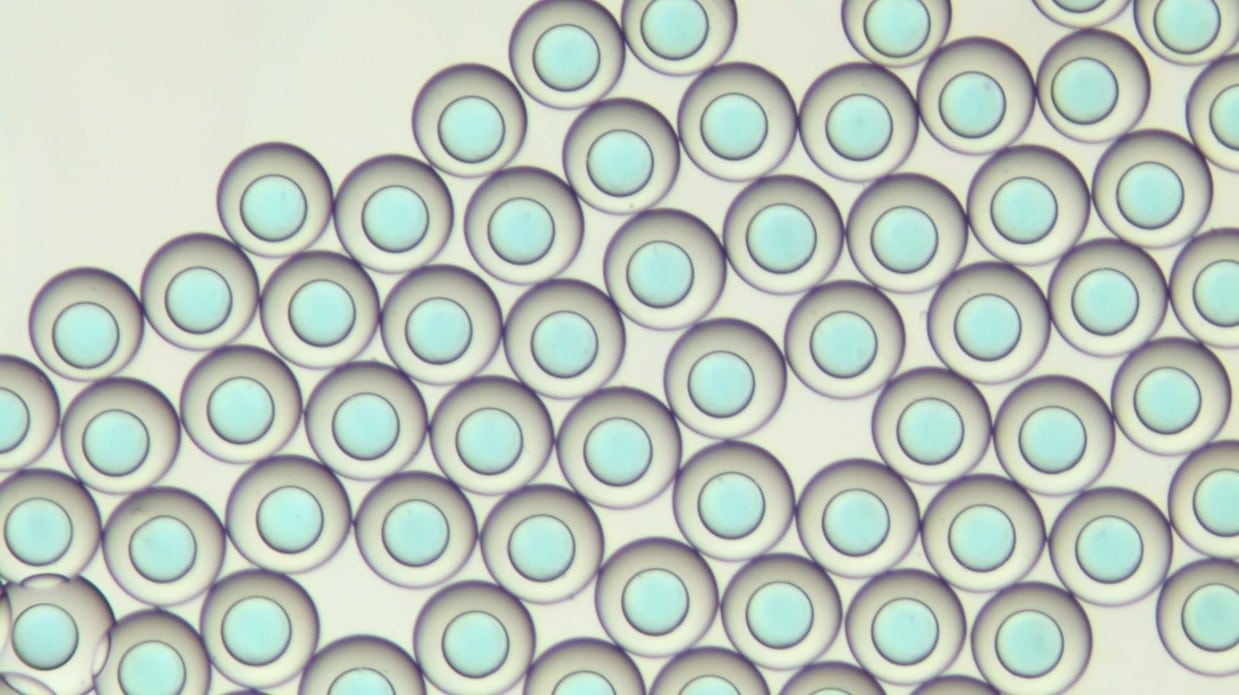

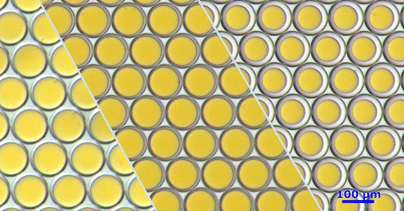

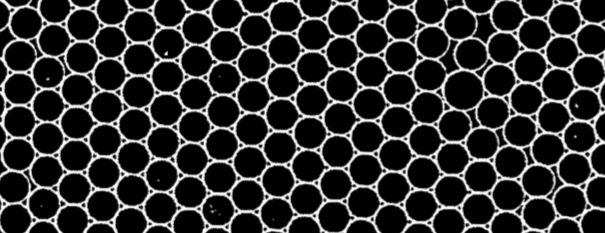

Droplet-based microfluidics produce highly monodispersed droplet and microcapsule/microparticle production opposed to batch emulsion methods and provide an “In-line” continuous droplet production process.

Formulation

The encapsulation of active ingredients to create flavors or fragrances for cosmetics and food products is a key part of their formulation. A challenge of droplet generation applied to encapsulation is to prevent the leakage of the encapsulated species.

The possibility to encapsulate these compounds allows users to control the release of the compound and improve pharmacokinetics. Modern drug encapsulation methods allow efficient loading of drug molecules inside nanoparticles, thereby reducing systemic toxicity associated with drugs.

Targeting nanoparticles can enhance the accumulation of nanoencapsulated drugs at the diseased site.

Next generation sequencing (NGS)

Encapsulation of a single cell inside a droplet increases NGS efficiency. The ability to study cells at single cell level using droplet based systems combined with NGS techniques allow for the sequencing of mRNA from a large number of cells.

The power of this technology, combined with droplet generation, resides in the fact that during sequencing, one can distinguish where the original information came on a cell-to-cell basis. This allows one to make a gene expression map of the cell, or even to distinguish cell populations within a tissue.

Drug discovery

In-vitro cell culture is a fundamental component of biological production systems and biotechnological research. The ability to grow cells outside of their natural environment offers many industry solutions from the high quantity production of enzymes to cell toxicity studies and drug discovery.

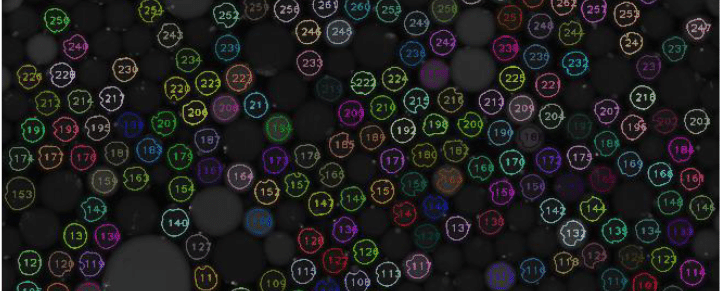

Droplet generationallows one to encapsulate single or multiple cells into tiny droplets of pL volume which are generated at a rate of approximately one thousand per second.

Diagnostics

A key measurement challenge in diagnostic research involves identifying small changes in nucleic acid sequences that are commonly associated with genetic diseases such as Down’s syndrome and many cancers.

Digital PCR (dPCR) carries out a single reaction within a sample as standard PCR, however the sample is separated into a large number of partitions where reactions take place in each partition individually. This is an excellent solution to partition a sample, and dPCR technology that makes use of droplet microfluidics is often called droplet digital PCR (ddPCR).

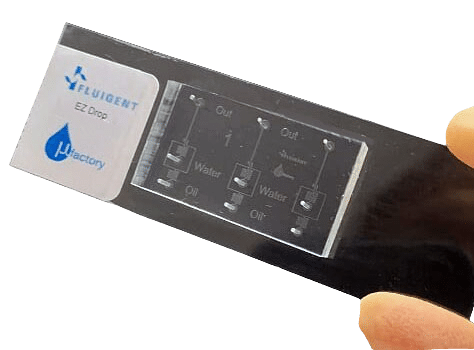

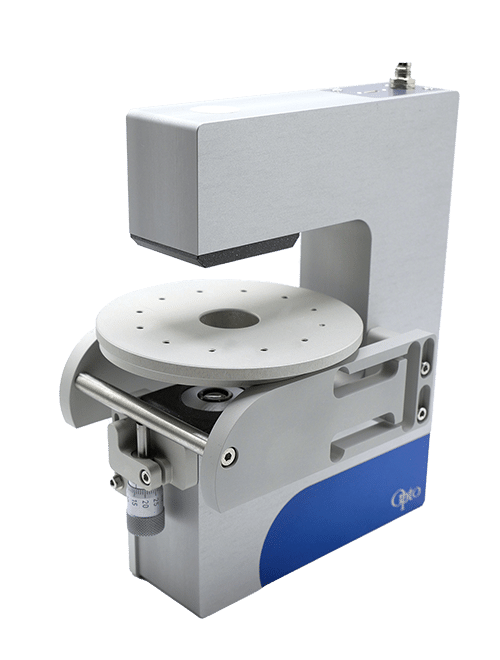

How to control droplet size and volume using fluid handling technology ?

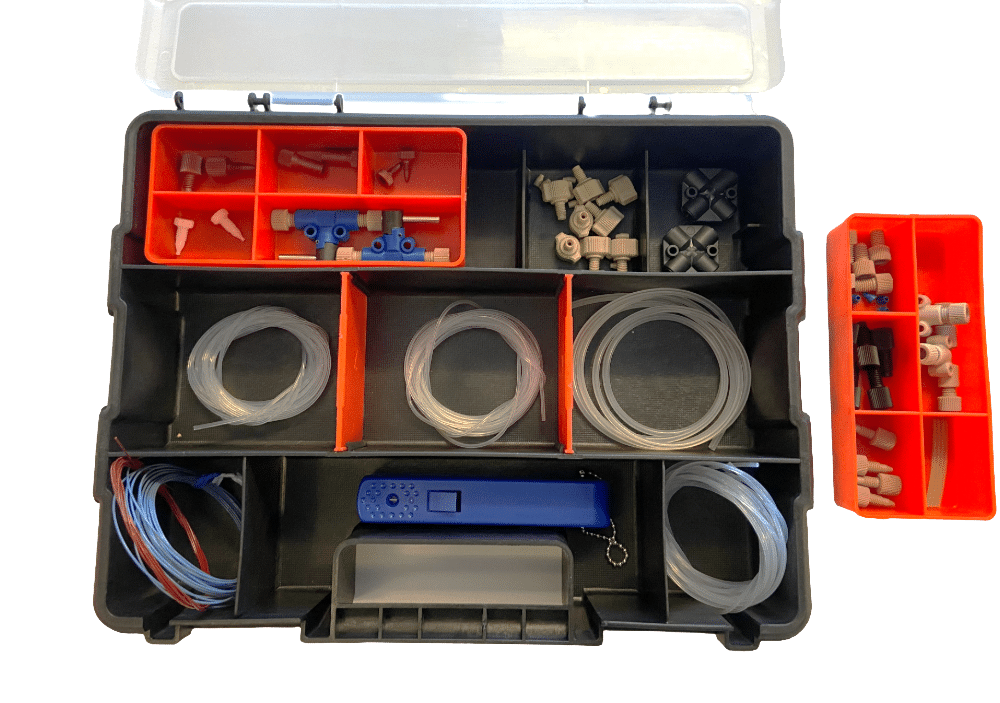

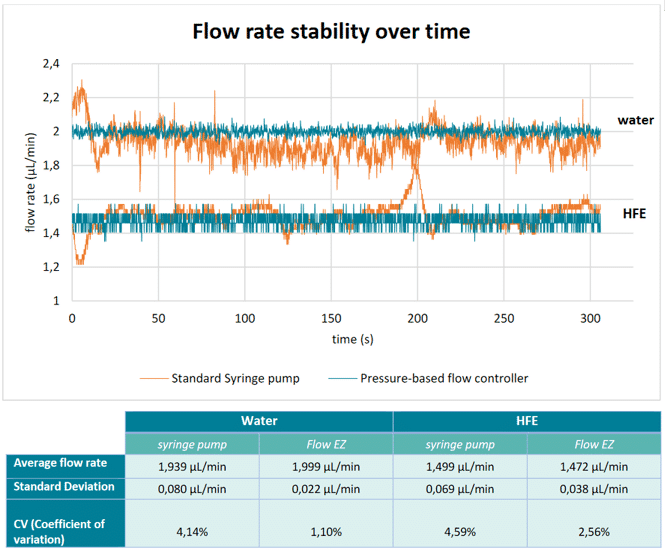

When it comes to particle or droplet generation, having control of the fluid delivery system is important. During particle or droplet production, the flow rate of each phase must remain constant and stable to allow the production of monodisperse droplets.

The ability to control the flow rate of each phase allows for more control over the process, precisely and easily regulating the size of the droplet or particle generated.

Which flow control system to generate monodisperced droplet ?

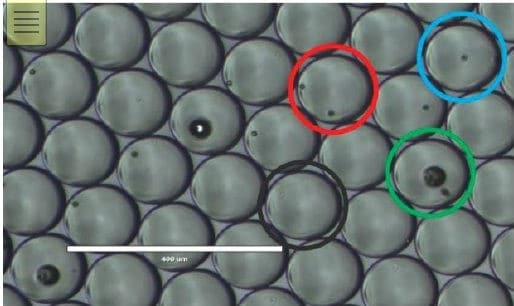

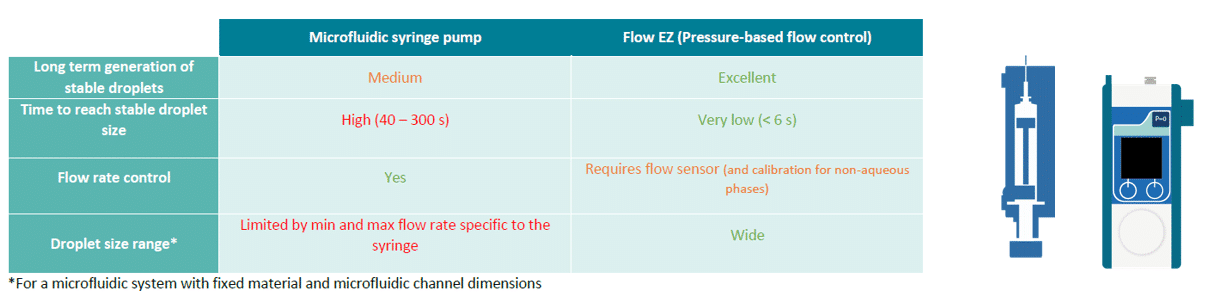

Flow rate stability is critical for having repeatable reactor volumes and reproducible results. Syringe pumps are commonly used for generating droplets in microfluidic experiments. Depending on the model in use, syringe pumps show limited flow control.

As a consequence, the droplet size (proportional to the flow rate), is affected. The actual flow rate cannot be controlled with syringes or peristaltic devices. The flow rate value is displayed on the device, but no information on the time required for reaching a set flow rate is given.

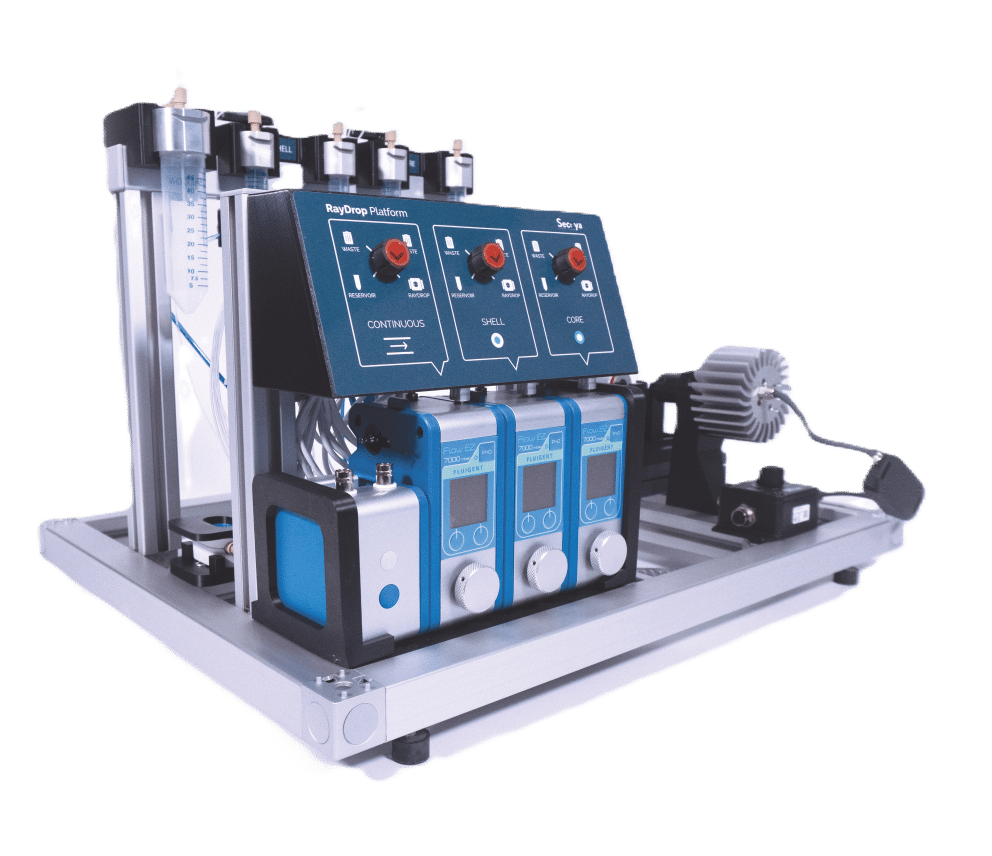

The time for flow equilibrium may vary depending on the microfluidic setup, and flow rate can oscillate depending on the instrument. An alternative to syringe pumps for the generation of droplets are pressure-based flow controllers. These show high-precision flow control and fast response times. Read more on the expertise page.

How are liquid droplets created with microfluidics pressure controllers?

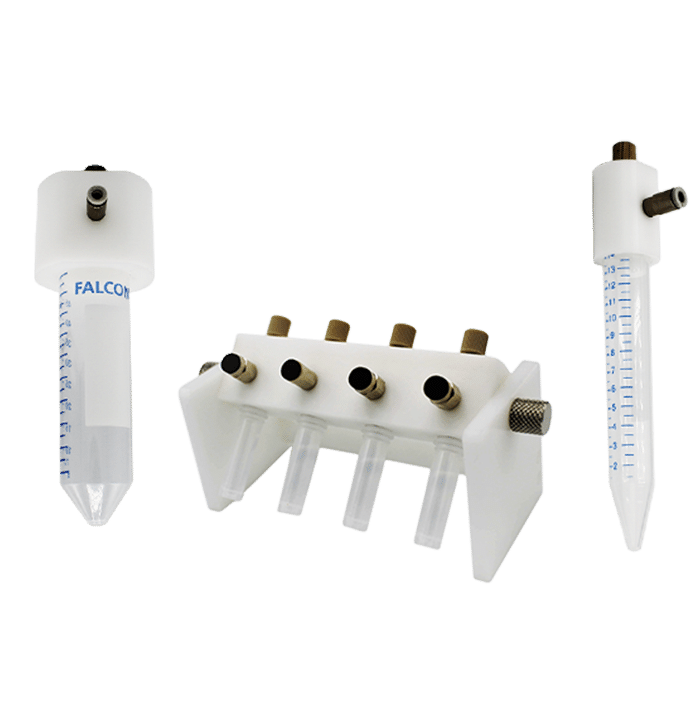

To underline the importance of pressure control, our application note compares the production of water-in-oil emulsions using microfluidic syringe pumps to pressure-based flow controllers. Droplet size, stability, and the time required to reach several droplet diameters are dependent on each instrument.

Resources

-

Microfluidic Application Notes Encapsulation of Cells In Small Double Emulsions Read more

-

Microfluidic Application Notes Encapsulation of multiple emulsions in a single droplet Read more

-

Microfluidics Case Studies The Hebrew University: Encapsulation and culture in 3D hydrogels for Single cell sequencing Read more

-

Microfluidics Case Studies University of Cambridge: Microfluidic GUV production and testing Read more

-

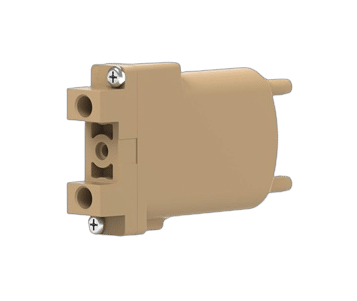

Expert Reviews: Basics of Microfluidics The Raydrop | A new droplet generation device based on non-embedded co-flow-focusing Read more

-

Microfluidic Application Notes Double Emulsion Generation Read more

-

Microfluidic Application Notes Microfluidic Chitosan Microcapsules Production Read more

-

Microfluidic Application Notes Alginate Microbeads Production Read more

-

Microfluidic Application Notes PLGA Microparticles Synthesis Read more

-

Microfluidic Application Notes UV-Crosslinking of Microcapsules Read more

-

Microfluidic Application Notes UV-Crosslinking of Microparticles Read more

-

Expert Reviews: Basics of Microfluidics Microfluidic Droplet Production Method Read more

-

Expert Reviews: Basics of Microfluidics Flow control for droplet generation using syringe pumps and pressure-based flow controllers Read more