Combining Microfluidics and Spectroscopy

What Applications Can Microfluidics Be Combined With Spectroscopy?

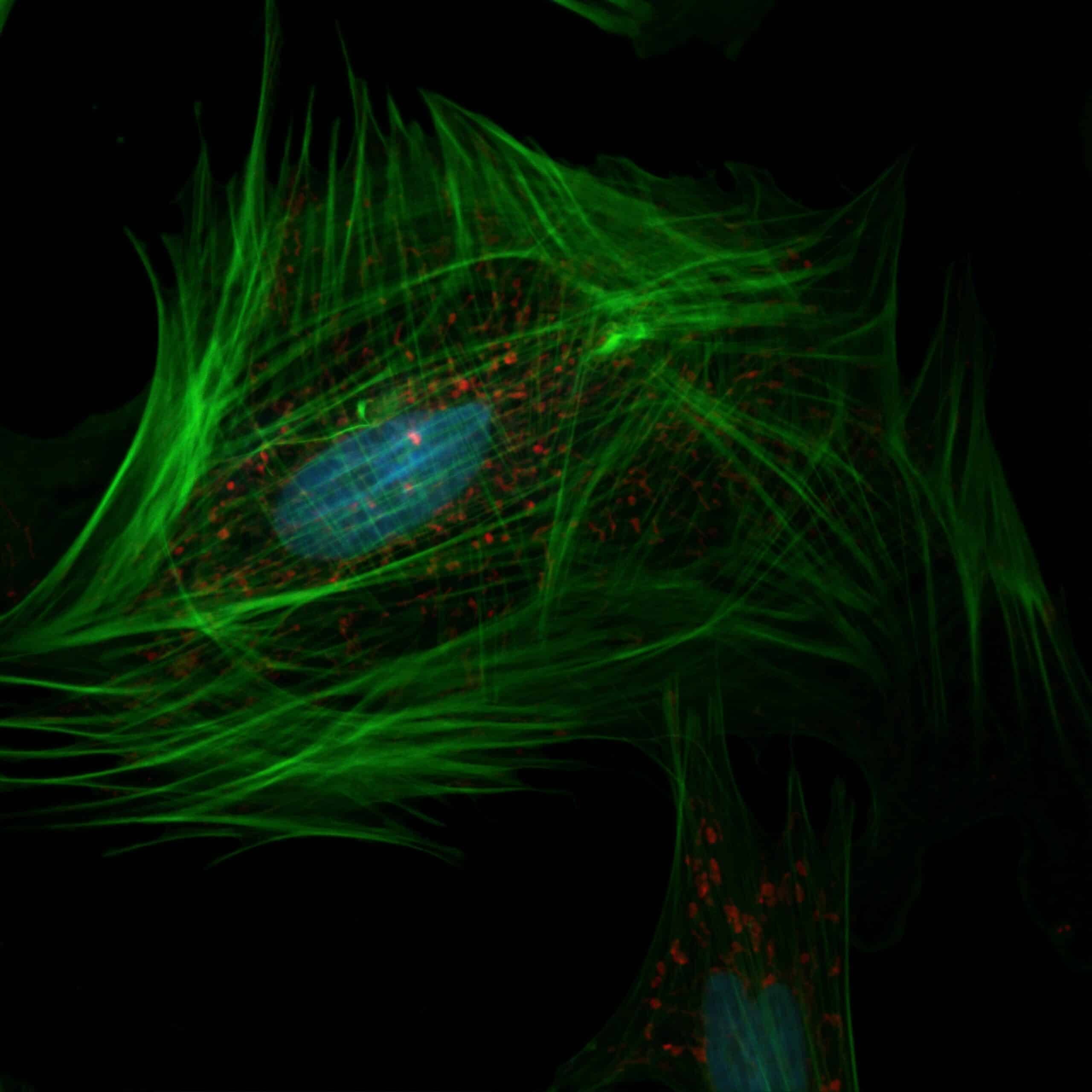

In-situ analysis of biological samples or live visualization of kinetics is a common application of microfluidics combined with IR or Raman spectroscopy.

Analyzing In-situ with flow instead of static conditions brings many advantages. Controlling the flow allows easy knowledge of the time and space of the biochemical reaction. It can obtain several points of measure on a reaction in one experience for faster, more precise and easier results.

A modular fluidic system to follow reaction on chip under spectrometer is the future of in-situ analysis.

Chemical reaction monitoring with inline spectroscopy brings precise and quick information. Microfluidic flow minimizes the quantity necessary to be taken.

How to Use Microfluidics in Spectroscopy

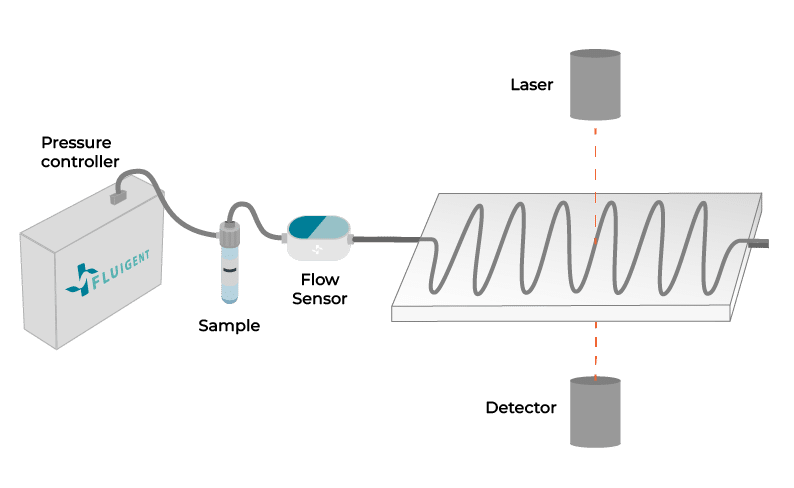

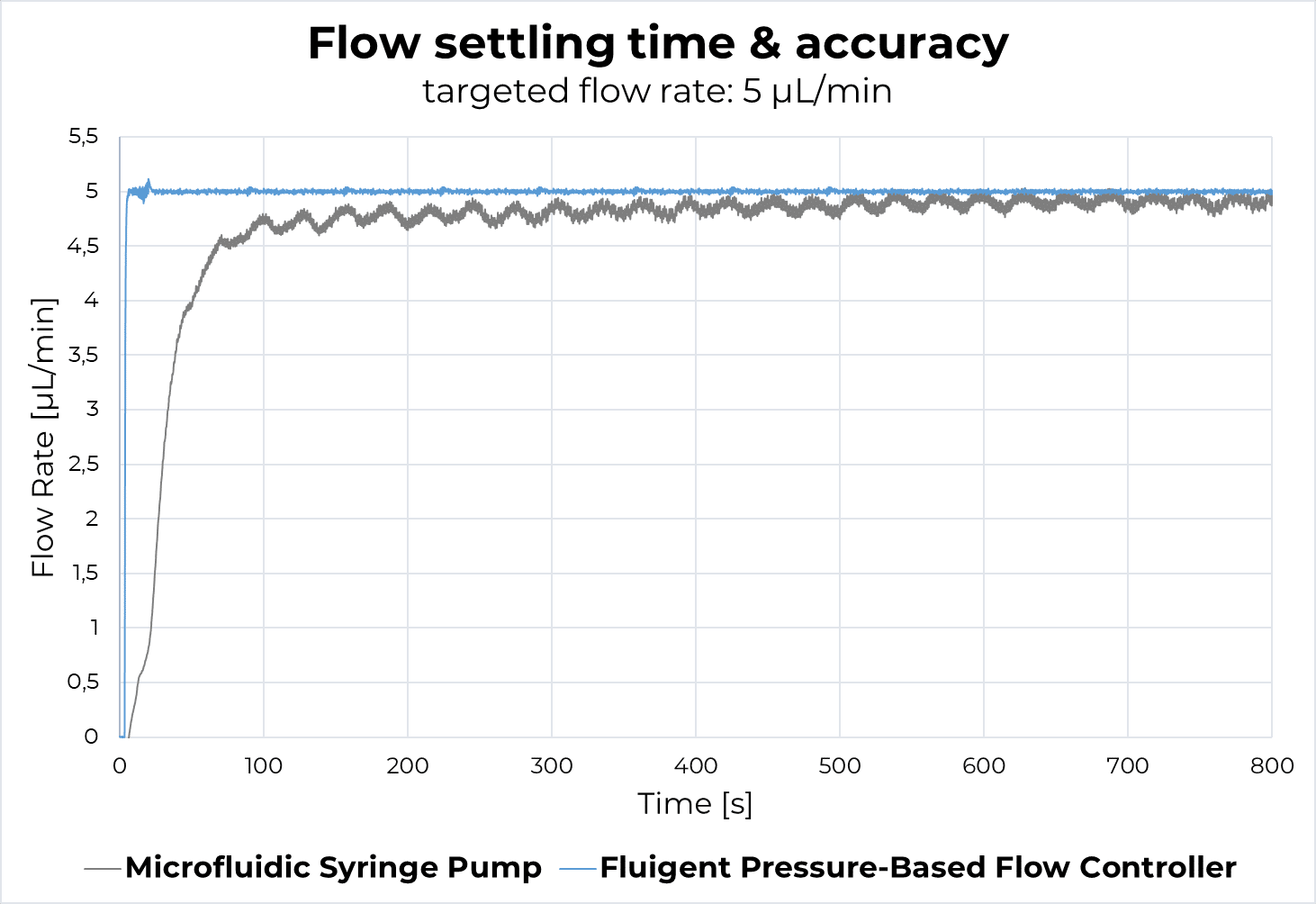

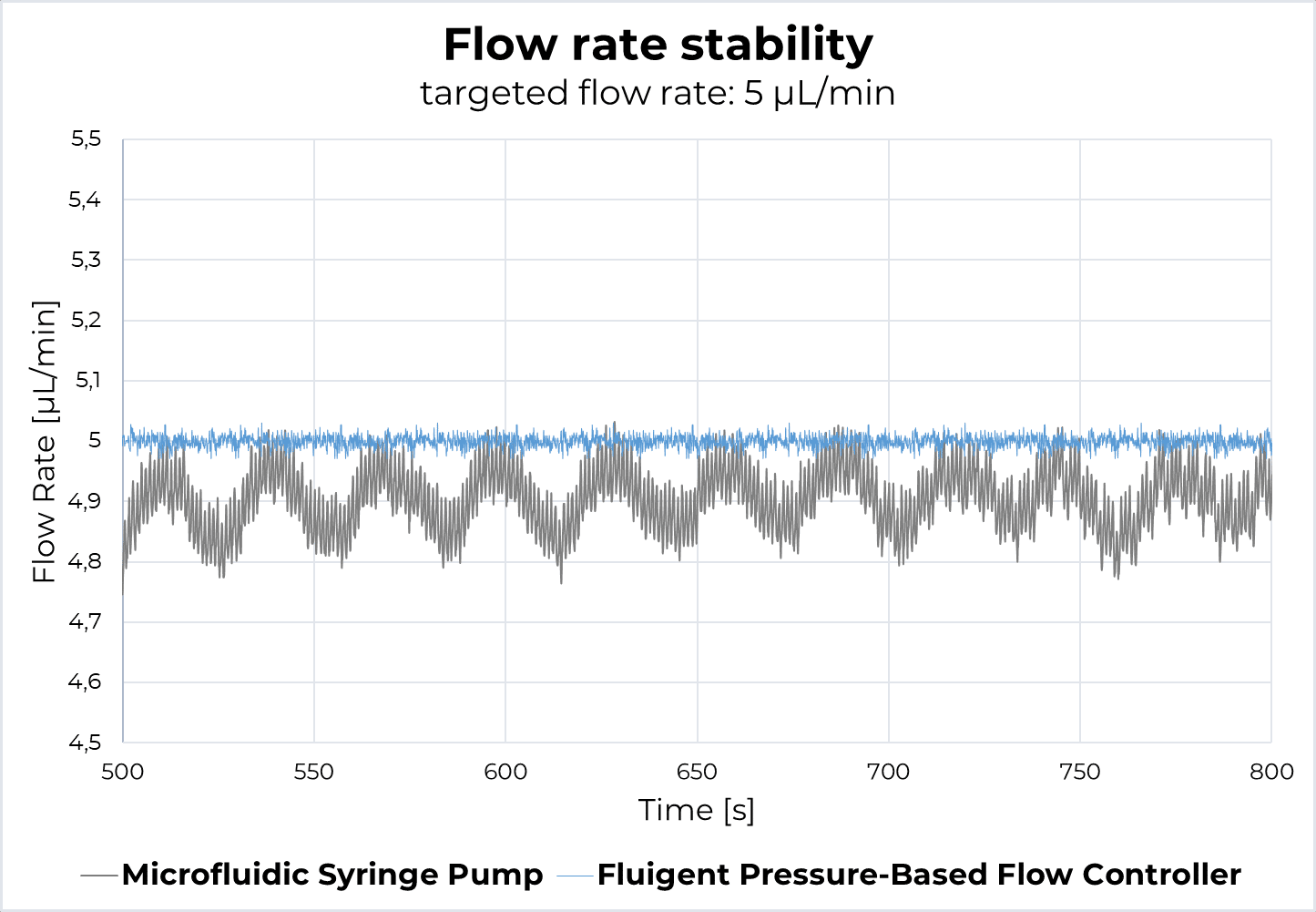

Spectroscopy can be combined with on-chip microfluidics for matter characterization, either in continuous flow or droplets. As the applications require an extremely precise flow rate, pressure controllers are a valuable alternative to syringe pumps. Pressure controllers also allow a bigger input volume, which can be a requirement for some applications.

Fluigent products have been used in spectroscopic applications such as electrospray ionization in mass spectrometry (1). The flow stability provided by pressure controllers compared to other microfluidics devices insures better results.

Figure 2: comparison between an OEM syringe pump (grey) & an OEM pressure-based flow controller (blue)

Sample Preparation

An automated microfluidic sample preparation instrument can bring a spectroscopy experiment to the next level. Automated sampling from a microbioreactor allows for the continuous control of kinetics.

Automated Inline Dilution and Filtration for Small Molecule Analysis

Inline dilution brings precision to analysis of biological samples such as enzymes. Diluting as close as possible to the measurement limits errors and preserves the biological integrity of the samples. With automation, the dilution can be continuous and increases the reproducibility of the results.

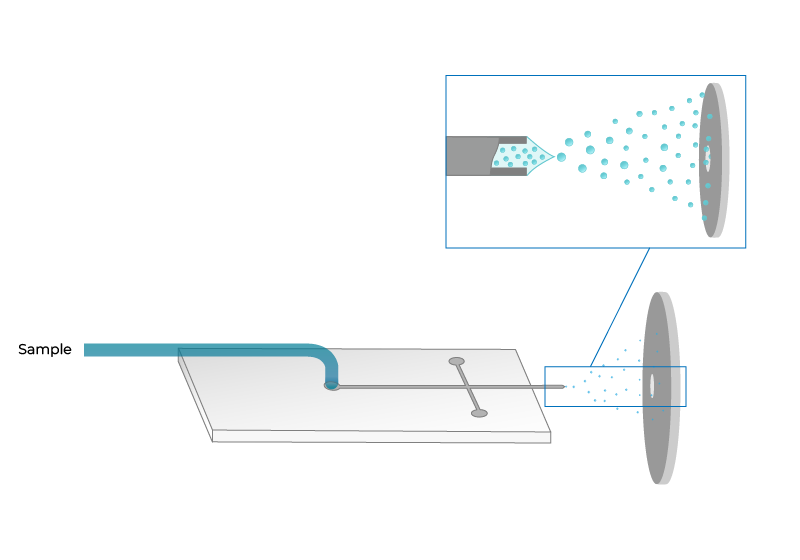

Electrospray

Electrospray is a mass spectrometry technique that requires an extremely low and stable flow rate to enter the electrospray to ionize particles.

Using microfluidic pressure controller to control the flow rate is a cost-effective solution with many advantages. The pulseless flow rate and the volume of the sample bottles are advantagous compared to syringe pumps.

Apply Our Microfluidic Expertise to Your Spectroscopy Applications

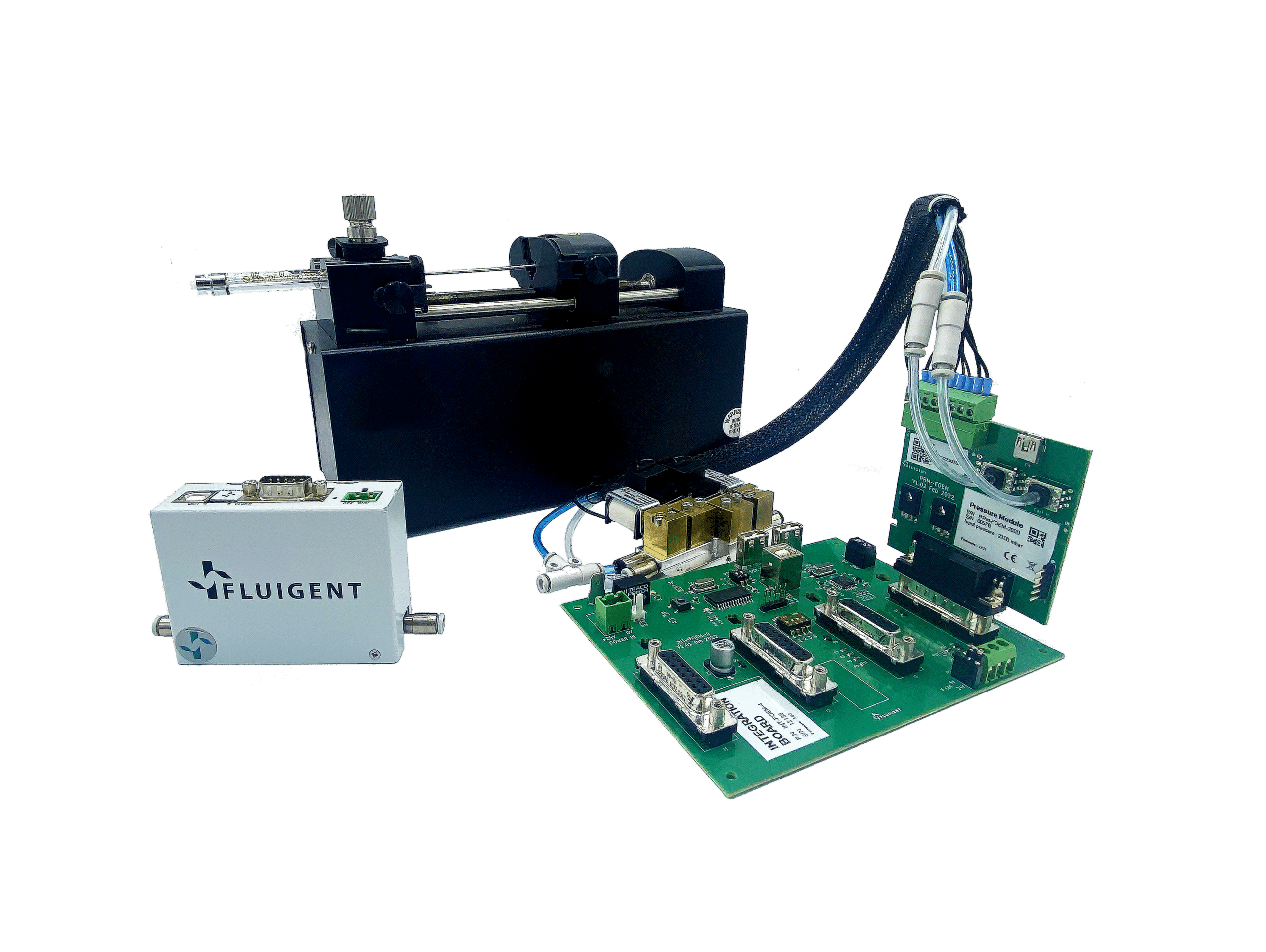

Pressures Controllers and OEM Parts

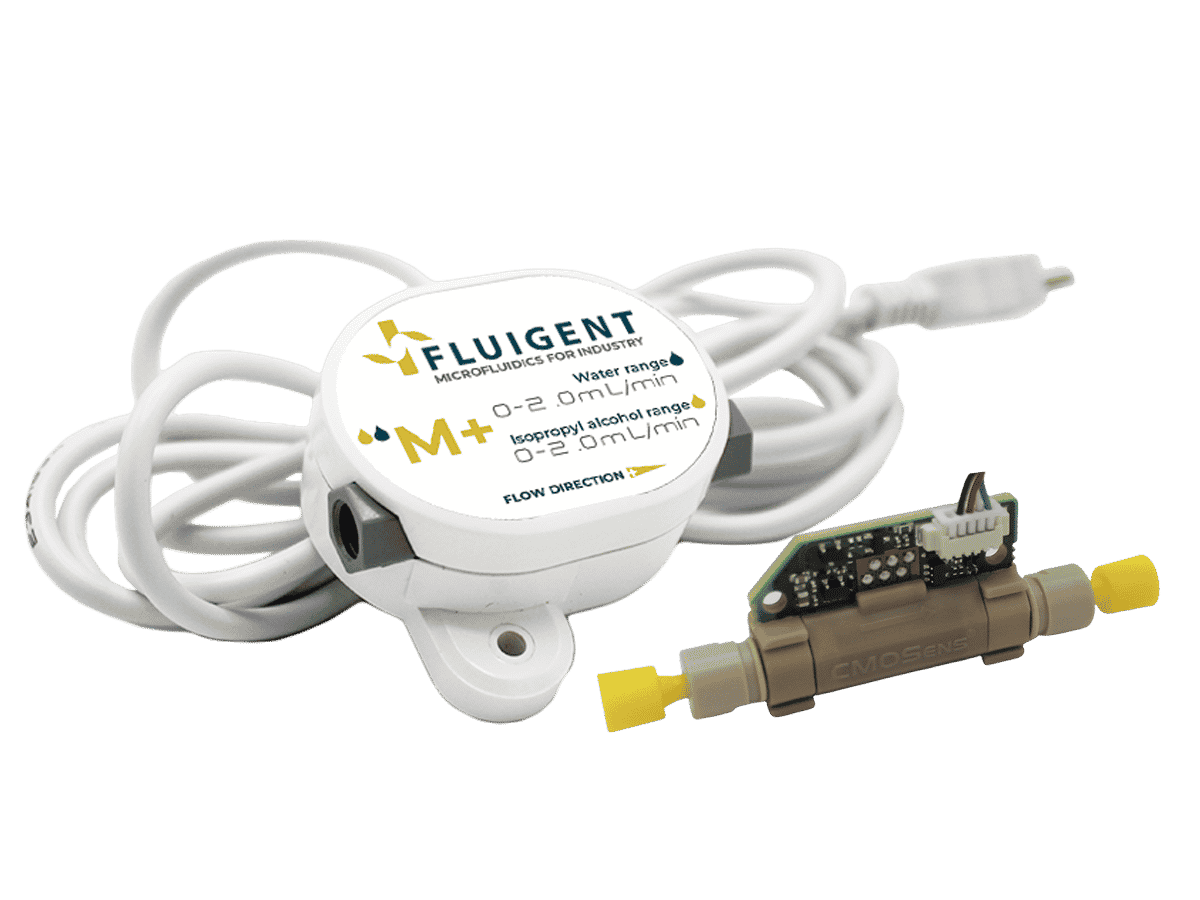

Our OEM pressure controllers are ready to use with a compact design for easy integration with your products. Benefits include:

- High-quality pressure control

- Pulseless and highly stable flow rate

- Contamination-free: not in contact with liquid

- Cost-effective: reduced reagent consumption

Fully Customizable System

We offer custom microfluidic device development to provide the system you envision.

By partnering with us, customers benefit from Fluigent’s portfolio of products, technologies, patents, and more than 15 years of experience with microfluidic technology. We combine our expertise and knowledge to design and manufacture the highest quality custom microfluidic devices. Partner with Fluigent to accelerate your product time to market.

Reference

Yu, C., Tang, F., Qian, X. et al. Multi-channel microfluidic chip coupling with mass spectrometry for simultaneous electro-sprays and extraction. Sci Rep 7, 17389 (2017). https://doi.org/10.1038/s41598-017-17764-6