Localization microscopy and flow control for multiplexing

The perfect flow management solution dedicated to your localization microscopy application

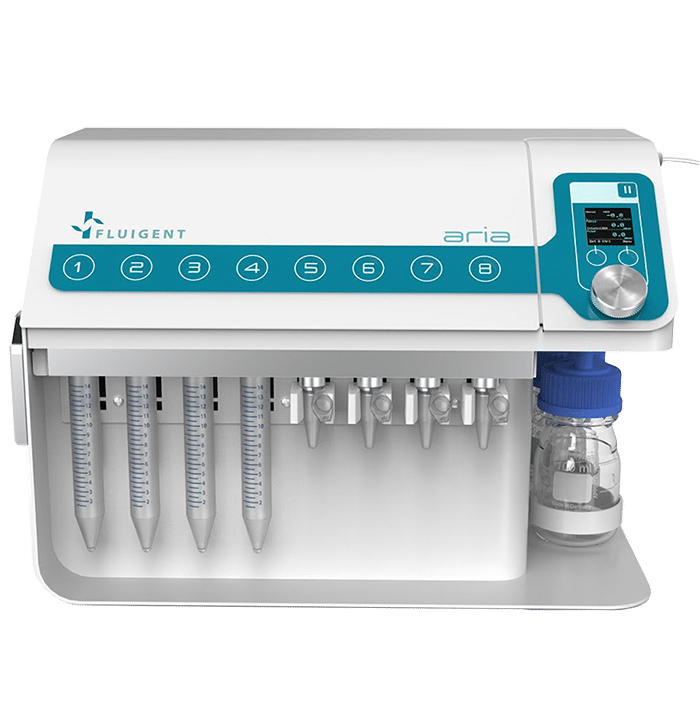

Fluigent’s software-controlled, automated, and fully integrated solution is the only commercial system that offers sequential injection for multiplexed localization microscopy capabilities. We also offer customization services based on our standard sequential injection device, Aria, to perfectly fit your requirements (hardware, software, branding, etc.).

Moreover, our sequential injection solutions provide the added benefits of:

- Automation and flexible configuration of fluidics sequences

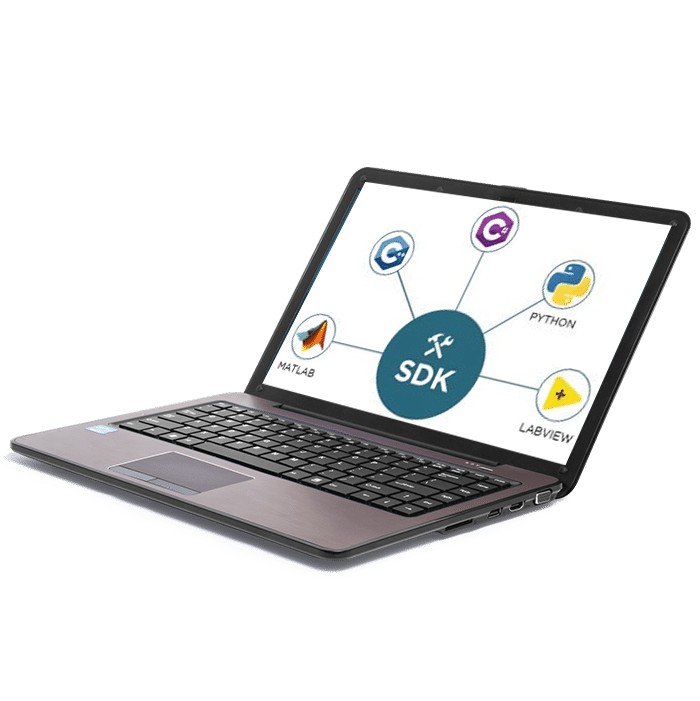

- Easy integration through our software and SDK

- Best performance through Fluigent’s pressure-driven technology

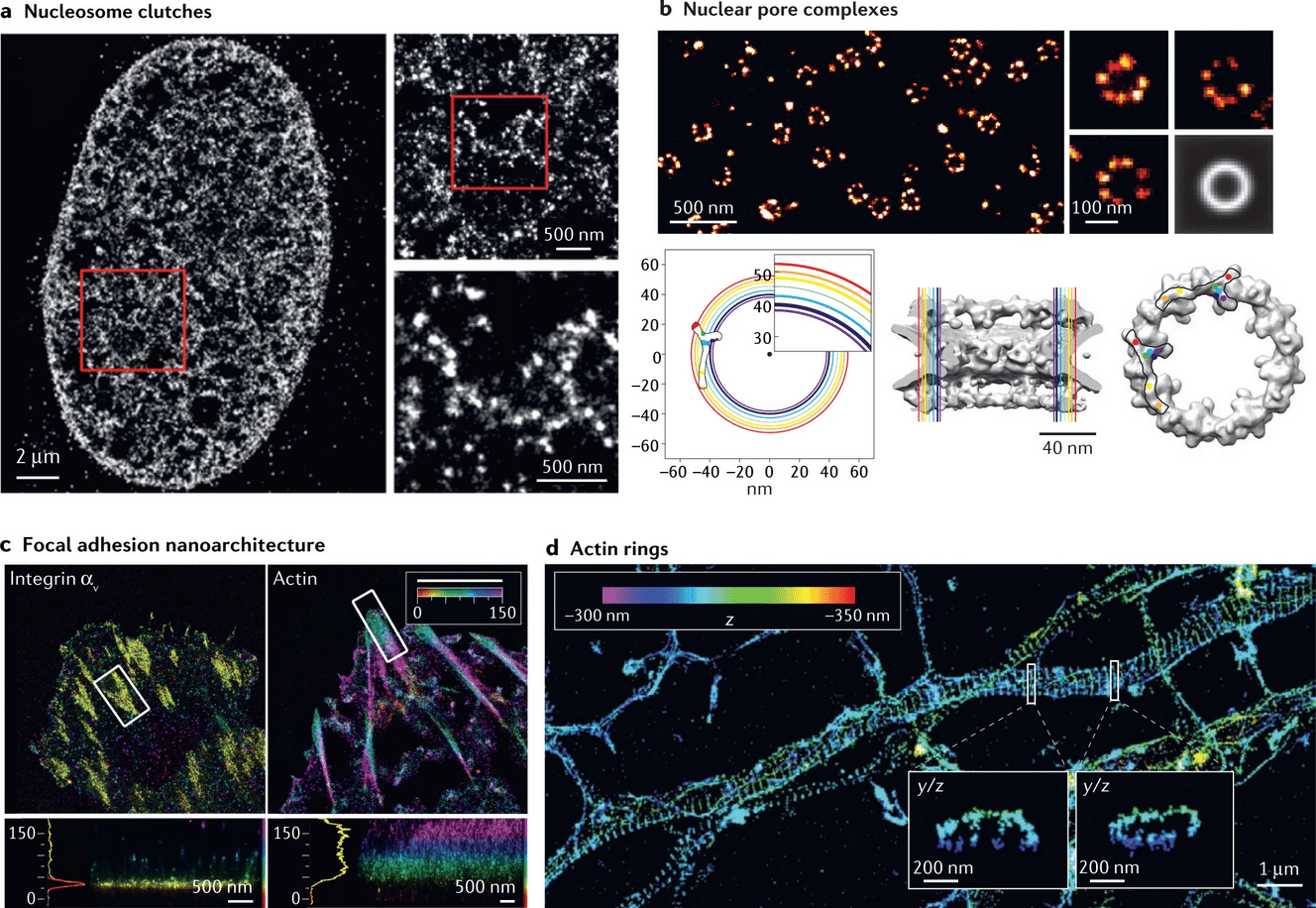

What is single-molecule localization microscopy?

Single-molecule localization microscopy (often called SMLM) describes a family of powerful imaging techniques that dramatically improve spatial resolution over standard microscopy techniques and can capture images of biological structures at the molecular scale1.

In single-molecule localization microscopy, individual fluorescent molecules are computationally localized, and the localizations are used to generate a super-resolution image. Sub-applications include oligo and refresh STORM, DNA PAINT, multiplexed antibody labeling, cell biology, neuroscience research, and others.

Why is microfluidics used for SMLM?

A typical single-molecule localization microscopy workflow includes fluorescent labeling, sample preparation, and image acquisition in fixed and live cells.

1- Increase labeling targets

Applications are developing in localization microscopy where the number of targets for imaging far outstrips the number of probes that can be chromatically separated. Sequential labeling with microfluidics allows for a much larger number of targets to be addressed.

2- Reduce protocol failure and secure reproducibility

In addition to being extremely time-consuming, manual injection or standard pipetting can harm biological samples for such applications:

- Disparate injections increase variability (5.7% intra-individual imprecision and 8.1% inter-individual imprecision for pipetting 10 µL)

- Turbulent flow can damage the sample

- Touching container sides can cause contamination

- Pipetting with an angle, failure to pre-wet tip, and tip wiping can increase chances of under-delivery and loss of sample.

Microfluidics allows users to overcome the above limitations as it permits the delivery of highly controlled microliter flow rates (down to a few nL/min, with an accuracy < 5% m.v) in a fully automated manner.

How Fluigent empowers localization microscopy

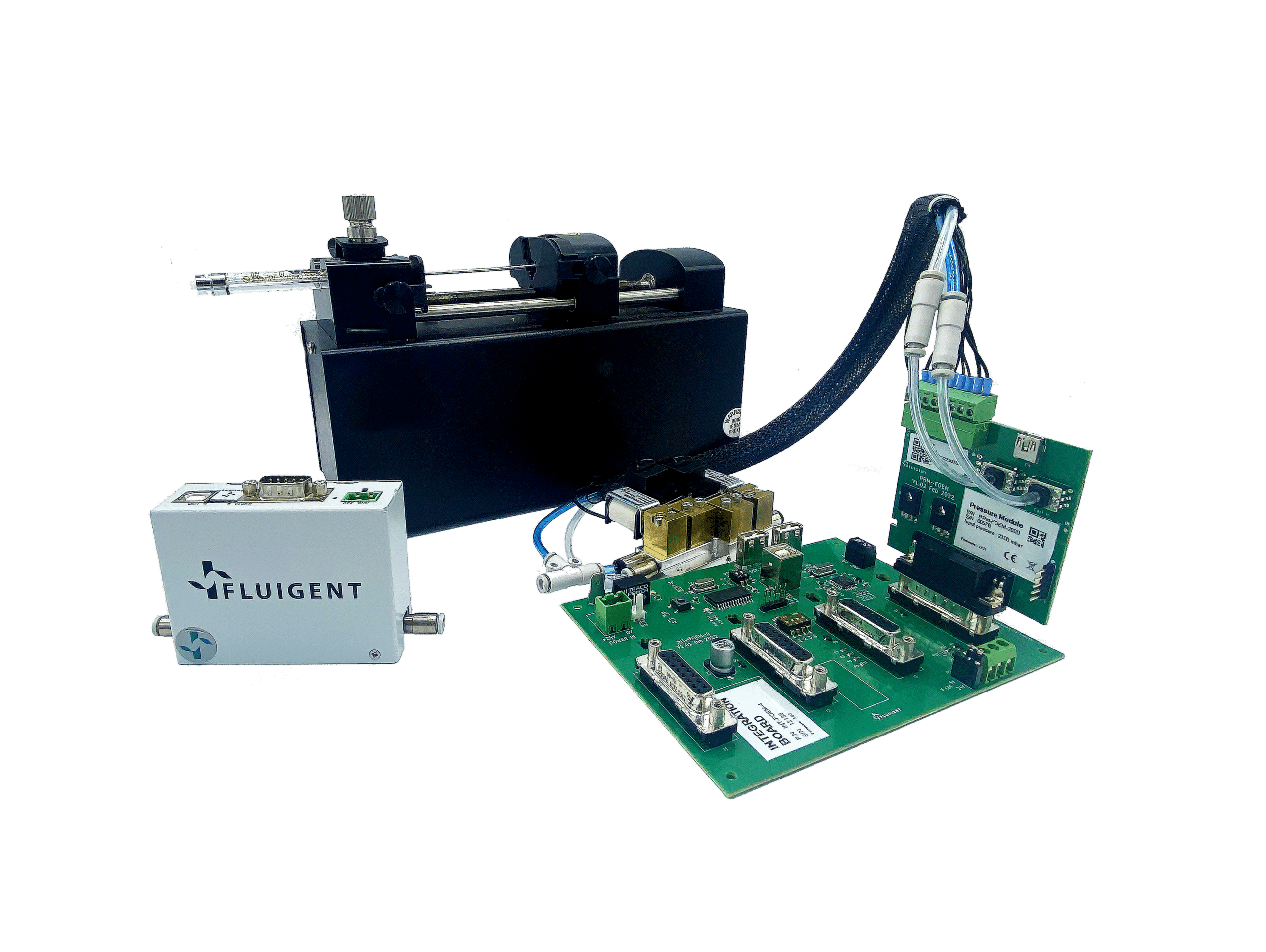

Building a microfluidic multiplexing system for sequential labeling requires expertise in microfluidic fluid management, electronics, and software, which demand dedicated engineering resources, time, and money. For instance, for sequential injection, after evaluating the physics of flow control, users must gather fluid delivery components, microfluidic valves,electronics, and other equipment. In addition, software is required to automate the flow control for microscopy.

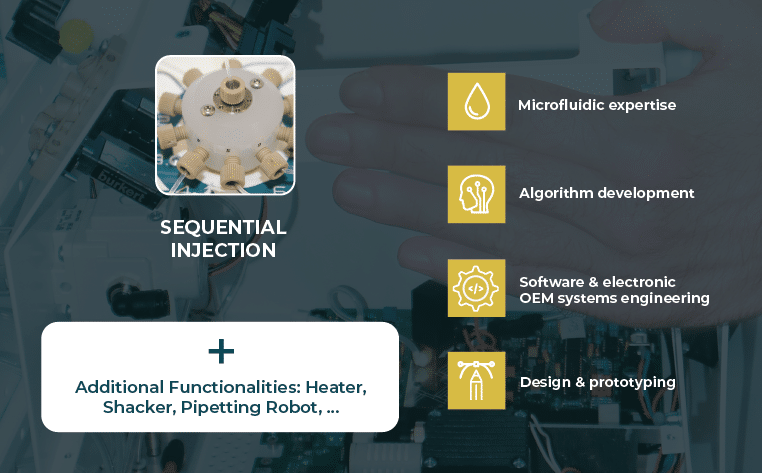

1- Fluigent has developed custom, on-demand multiplexing systems and OEM Automation Workflows dedicated to localization microscopy and live cell imaging.

The different functionalities developed that are related to our development are described below. They can be reused as bricks in a custom project and/or combined with our other modules. See why customers chose Fluigent for automating their sequential labelling workflow.

2- Improved flow performance via Fluigent’s patented pressure-driven flow management

Strong stability to ensure sample viability

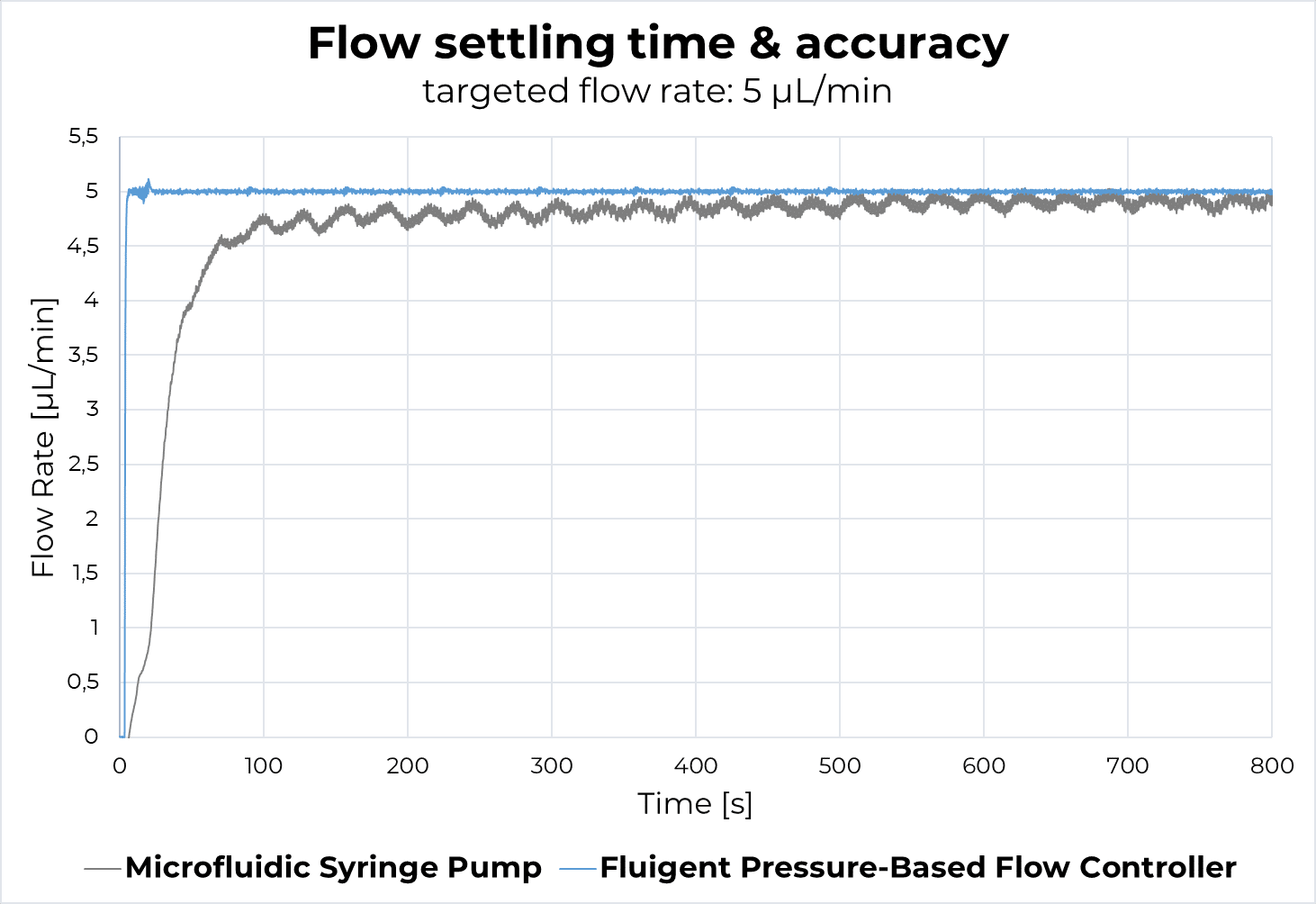

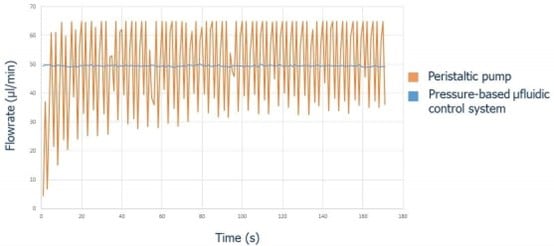

Our devices include Fluigent’s pressure-based flow control technology. Using pressure-driven flow control, the sample is smoothly injected into a microfluidic system. As there are no mechanical parts in contact with the fluids, pressure controllers can establish pulseless flows that cannot be obtained with peristaltic pumps, or even the most accurate syringe pump. Using Fluigent controllers, pressure stability with < 0.1% CV is obtained. This allows a new level of stability that is required for emerging applications. The graphs below show perfusion comparisons between Fluigent controllers and peristaltic and syringe pumps.

Flow rate features dedicated to microscopy applications

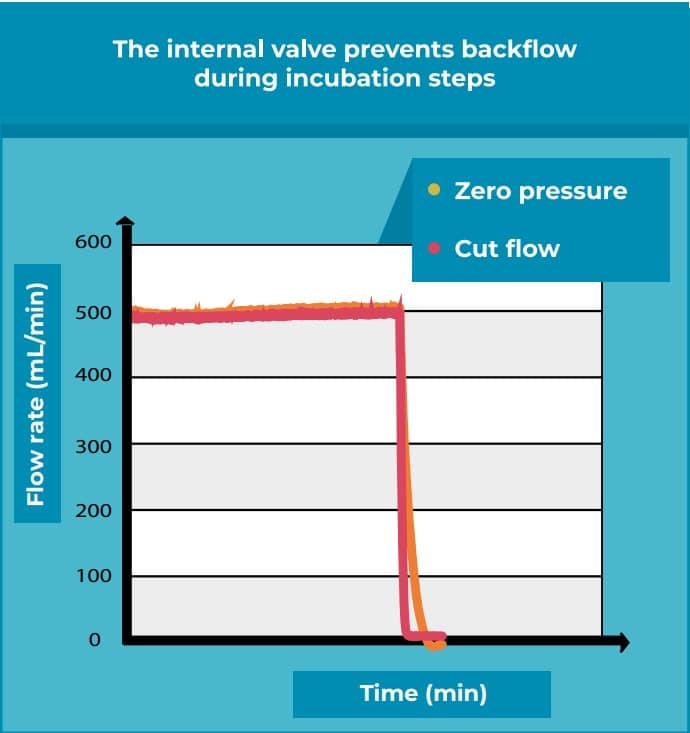

The addition of an on-off valve in the device guarantees that the flow is stopped when the user orders it to perform imaging. As illustrated by the adjacent graph, when using cut flow technology, the flow rate immediately stops when the desired volume is injected, preventing backflows.

Preventing backflow during incubation steps enables the microfluidic sequential injection system to switch quickly between injection and incubation steps, which is advantageous for microscopy studies. Another valve at the output just before the chip or the chamber allows the flow to run either towards it or towards the waste to flush the tubing between two successive injections. This valve is also useful for automated calibration and priming.

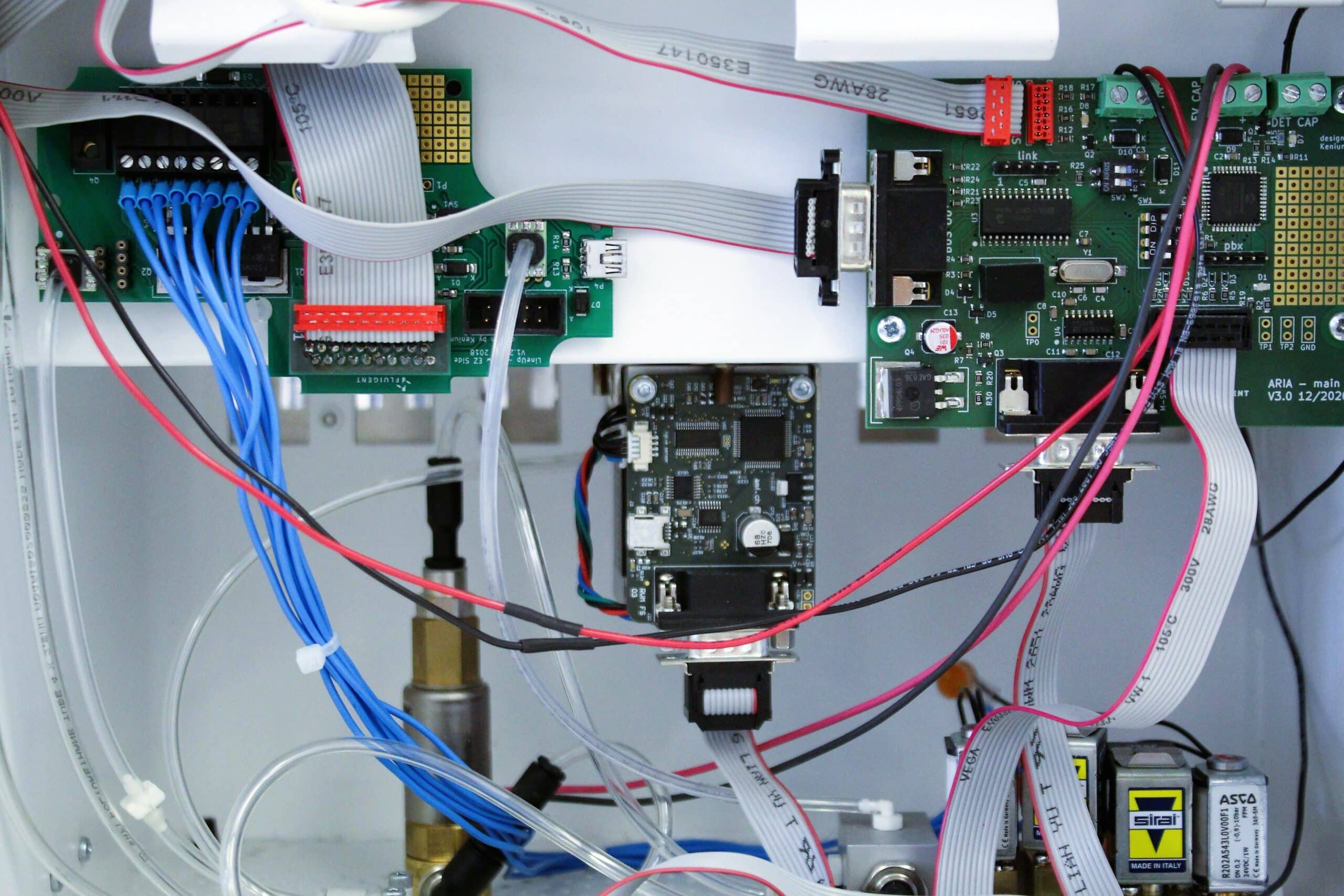

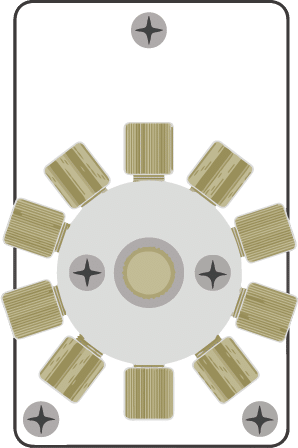

3- High-multiplexing capabilities through in-house microfluidic valve integration & automation

To offer multiplexing capabilities to our microscopy users, we developed automated sequential injection systems based on the integration and automation of several microfluidic valves (such as 11-port/10-way rotary valve, 3/2-way valves). They are accompanied by tailor-made electronics that ease connectivity and maintenance and mechanical integration that minimizes risks such as bubble formation and improves ergonomics. They are all controlled by our algorithm to work together with our flow control components in the most efficient and performant way and are integrated into a setup to obtain a fully automated system.

With such systems, several buffer reservoirs can be swapped out during an experimental workflow, enabling the multiplexing of many labels in one experiment. This makes it optimal for localization microscopy applications.

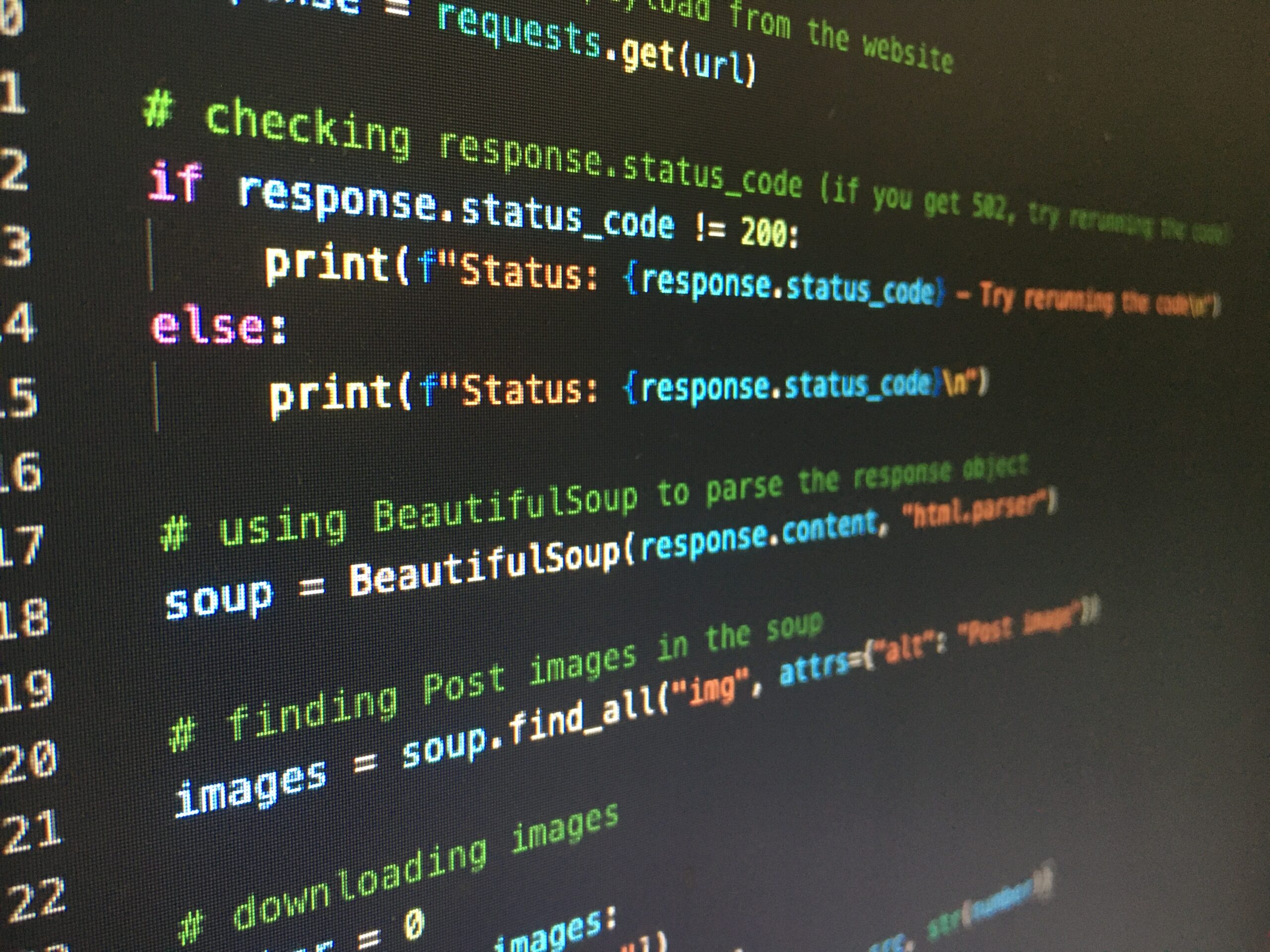

4- SDK and software for saving time, ease of use, and seamless OEM integration

Fluigent has developed software functions dedicated to multiplexing applications that allow users to fully automate liquid handling sequences for microscopy use. The perfusion device can automatically perform any perfusion protocol, offering the following benefits:

- Ability to fit any experimental design for accurate and reproducible preparation of samples for fluorescence microscopy

- Intuitive, time-saving, and easy to use: i

Individual methods can be created, saved, and recalled quickly for a run

- Enables long-term perfusion studies such as multicolor PAINT imaging

The features include:

- Flow management functions: volume injection, timed injection, reservoir selection, liquid flushing, etc.

- Sequencing functions: wait, wait for user, wait for TTL, Group, Loop

- Protocol loading & saving functions

- Data recording function

- TTL and TCP/IP functions

- Communication with external systems and wait for their signals as part of the protocols to perform other imaging processes while the perfusion protocol is paused

- Error functions (feedback on errors encountered during the protocol)

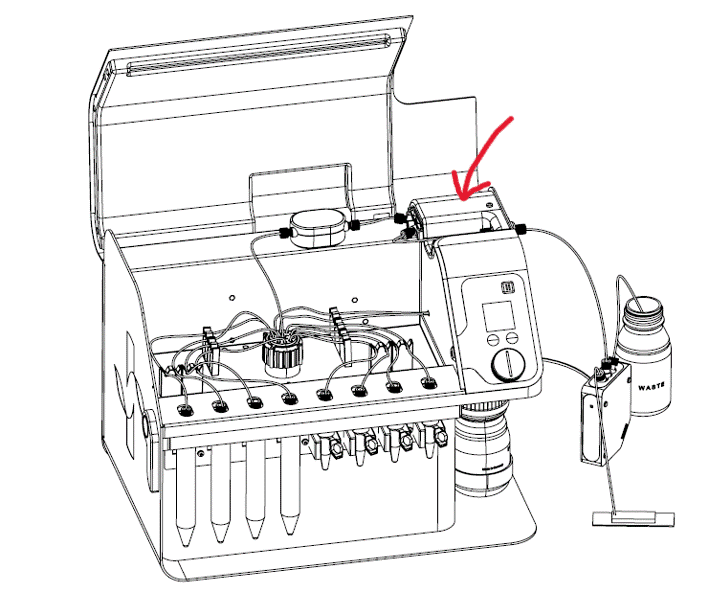

The standard software version is included in our end-user automated sequential injection system, Aria. Aria software gathers all the above functions, and provides an easy-to-use interface, allowing users to add flow management functions to create a complete fluidic protocol, seamlessly.

We provide a complete offer to address all your localization microscopy needs

1- Standard sequential injection system

We provide an on the shelf, ready-to order multiplexing dedicated to localization microscopy that allows the following benefits:

- Deliver up to 10 solutions

- Automate any protocols

- Dedicated Fluigent software and SDK

- Single output (1 sample) and serial output (9 samples) versions

Other available features:

- Local control thanks to a control panel

- Night mode to allow its use in a dark room for fluorescent microscopy

2 – Software

To provide a fully functional solution dedicated to your application, we can adapt our software to your needs. This includes custom interfaces and functional modifications. Software can be adapted to meet new requirements on pressure/flow rate couples, internal volumes, and additional functions for communication with your devices, which can include additional warnings, security functions, can be implemented. Software can also be customized to fit your company’s corporate identity charter.

3 – Fully custom system: from idea to production

If one requires a brand-new flow management system dedicated to his microcopy setup, we offer flexible, custom microfluidic device development to provide the system you envision. Custom functionalities can be added according to your needs and the modules included (integrated microscope module, temperature control, liquid mixing, flow sensors…).

By partnering with us, customers benefit from Fluigent’s portfolio of products, technologies, patents, and 15 years of experience with microfluidic technology. We combine our expertise and knowledge to design and manufacture the highest quality custom microfluidic devices. Partner with Fluigent to accelerate your product time to market.

- Most flexible solution

- Fluigent expertise

Reference

Lelek, M. et al. Single-molecule localization microscopy. Nature Reviews Methods Primers vol. 1 Preprint at https://doi.org/10.1038/s43586-021-00038-x (2021).

Related expertise

5 reasons to choose OEM pressure controllers over OEM syringe pumps for microfluidic applications

Read more

DFC, “Self-Learning” Microfluidic Flow Control Algorithm

Read more- Expert Reviews: Basics of Microfluidics

Key considerations for fluidic system integration

Read more - Expert Reviews: Basics of Microfluidics

Key reliability indicators for OEM components to ensure long-term performance of your flow control system

Read more