Microfluidics for Pharmaceutical Applications

Microfluidic technologies that provide control over fluid flows and mixing are emerging as an alternative to conventional bench methods. Microfluidic systems have revolutionized the traditional scale-up approach by replacing it with a more efficient method.

This innovative technique takes advantage of the compact size of microfluidic devices, significantly reducing the time required to go from formulation to production. Consequently, the adoption of microfluidic technologies has expanded beyond analytical applications to encompass large-scale manufacturing in various process industries, notably the pharmaceutical sector.

Recently, the market has witnessed a surge in the release and availability of microfluidic-based devices. These cutting-edge advancements have emerged from diverse sources, including small start-ups as well as established pharmaceutical and biomedical companies. As a result, these companies are increasingly developing microfluidics for pharmaceutical applications. This trend signifies the growing recognition and acceptance of microfluidics as a transformative technology with significant potential for enhancing efficiency and productivity in the pharmaceutical domain.

Microfluidics in Pharmaceutics

Drug delivery

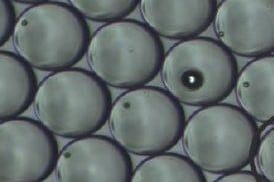

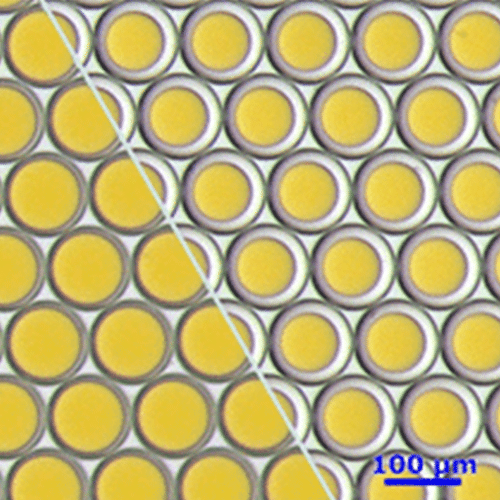

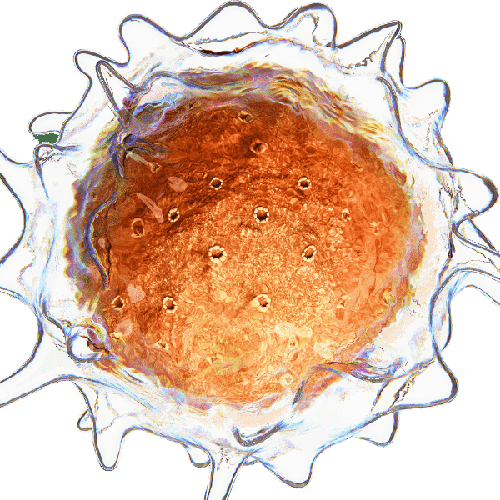

Microparticles and emulsions are used for a wide variety of pharmaceutical products including intravenous, intramuscular, ocular, or orally delivered compounds. Emulsions are also used as templates for polymer microparticles, lipid nanoparticles, or microcapsules. These are later used for drug delivery, with the emulsion being the active pharmaceutical ingredient (API) itself, or as an adjuvant for co-administration.

Droplet microfluidics technology produces multiunit drug delivery systems with precise dosage control, targeted release, and homogeneous distribution. Conventional methods struggle to achieve monodispersity (<5%) required for efficient drug delivery. Our technology revolutionizes drug delivery, offering improved treatment options and personalized therapies and advancing pharmaceutical development and patient care.

To learn more about droplet microfluidics for pharmaceutical applications, read our white paper about droplet microfluidics.

Disease modeling and characterization

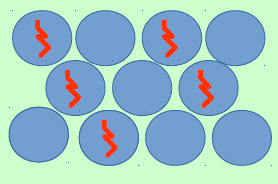

Animal studies are the current standard for evaluating potential treatments, but they often struggle to correlate with human outcomes due to physiological differences and genetic variations. These studies are costly, time-consuming, and raise ethical concerns. Human clinical studies face challenges due to individual diversity and research complexity. Microfluidic models in an organ-on-chip format offer a promising alternative, providing an efficient, cost-effective, and ethical approach for drug discovery and personalized medicine. This technology advances the field of pharmaceutics by enabling the development of predictive methods to evaluate new compounds and therapeutics. It then helps in disease modeling and characterization, enhancing the drug discovery and development process.

To delve deeper into the topic of microfluidics for pharmaceutical applications using organ-on-chip systems, read our OOC white paper.

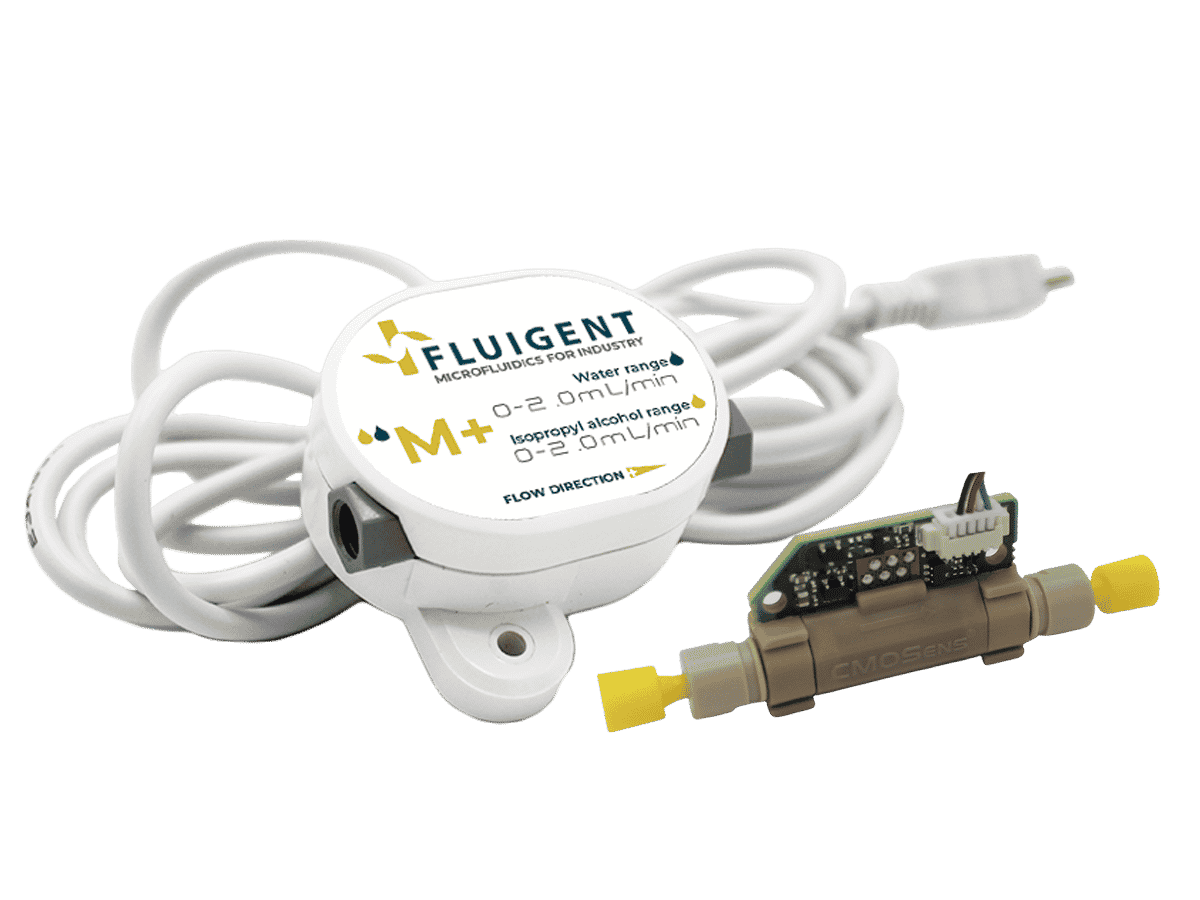

Related products

Research field

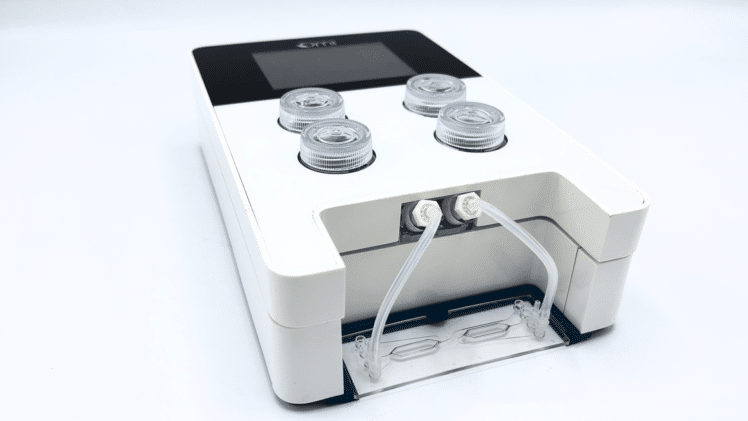

Encapsulation Platform for FACS

Platform for cell encapsulation in DE droplets

See the offer

Microfluidic flow controller

Flow EZ™

See the offer

Microfluidic Double Emulsion Device

RayDrop Double Emulsion

See the offer

Microfluidic Single Emulsion Device

RayDrop Single Emulsion

See the offer

Double Emulsion Generation Pack

Double Emulsion Generation Pack

See the offer

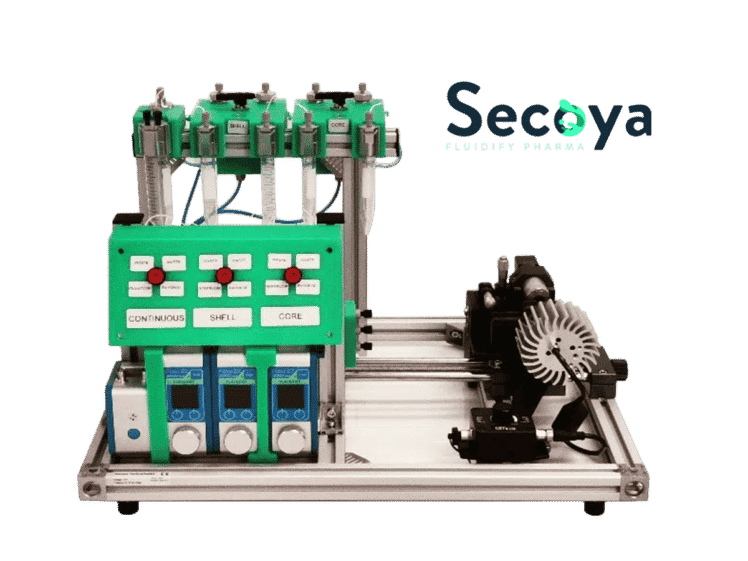

Microfluidic Complex Emulsion Production Platform

Platform for emulsions & droplets

See the offer

PLGA Microparticle Production Pack (Automation Pack)

PLGA Microparticle Production Pack (Automation Pack)

See the offer

Industrial field

Related Ressources

Looking for another market?

From the life sciences to the food industry, many applications require the use of fluids driven at flow rates from nanoliters to milliliters per minute. At such low flows, the success of these applications strongly depends on the level of control and automation of the fluidic operations.

These applications require flow control systems that are adapted for ensuring their success.