Non-Intrusive Flow Sensing Technology

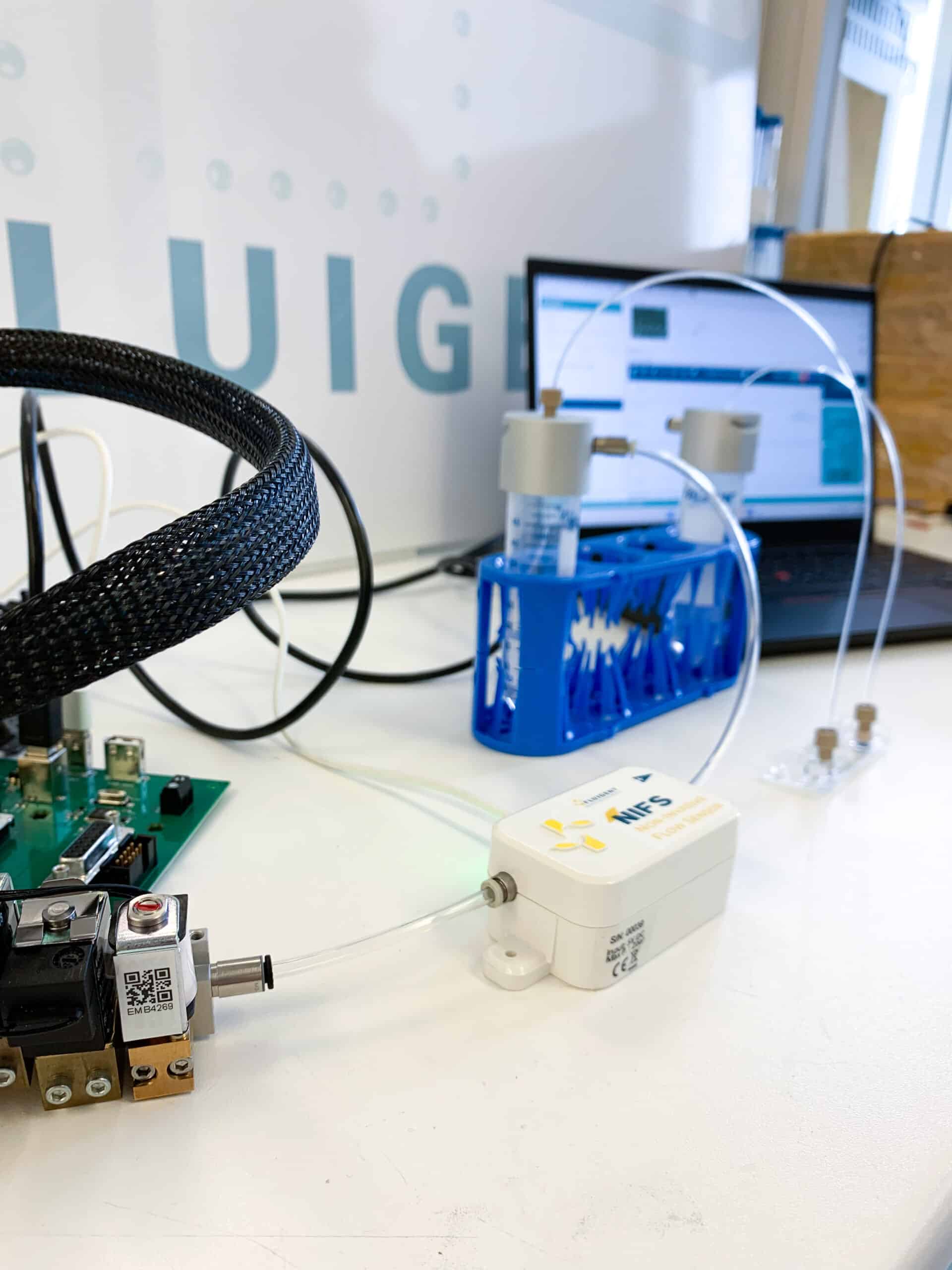

Fluigent has developed the first calibration-free and non-intrusive flow sensing technology dedicated to micro- and milli-fluidic applications (patent pending). It is well suited for biological applications that requires a sterile environment, or droplet microfluidics applications where different fluids are used.

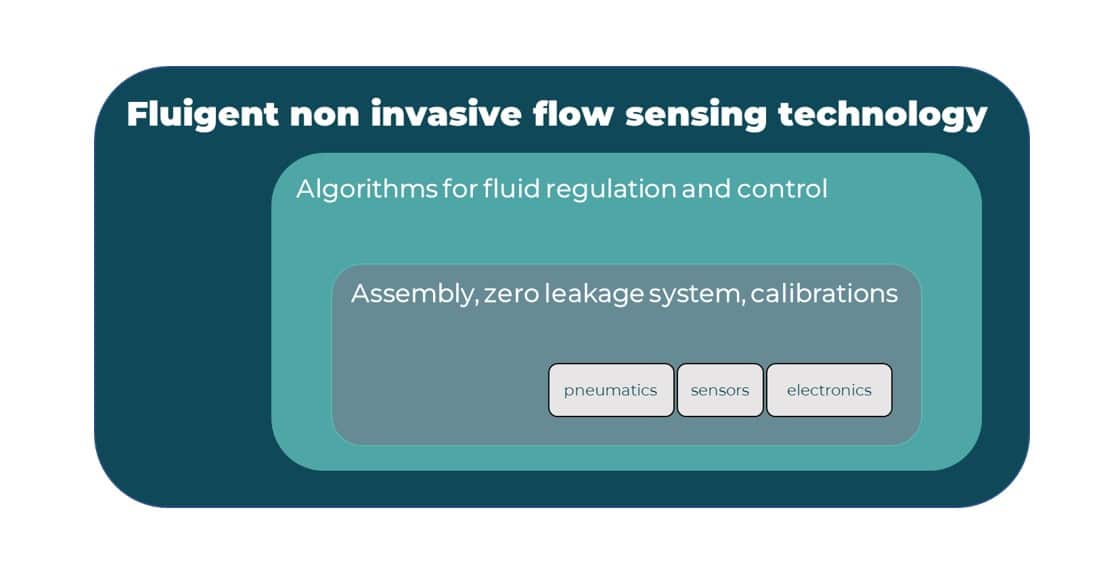

This technology is designed to be integrated into pressure-based fluidic systems, and works with Fluigent solutions. It combines sensing and pneumatic elements with well known Fluigent regulation algorithms.

This technology can be integrated in any custom project. Users will receive the following benefits:

- Contact-free: suitable for use when sterility is required

- No calibration needed: liquid-independent

- Suitable for Industrial use: can be integrated into many devices and systems

- High precision and accuracy: Fluigent regulation control

How does our non-intrusive liquid handling system work?

Fluigent expertise for fluid flow rate adapted to gas flow rate

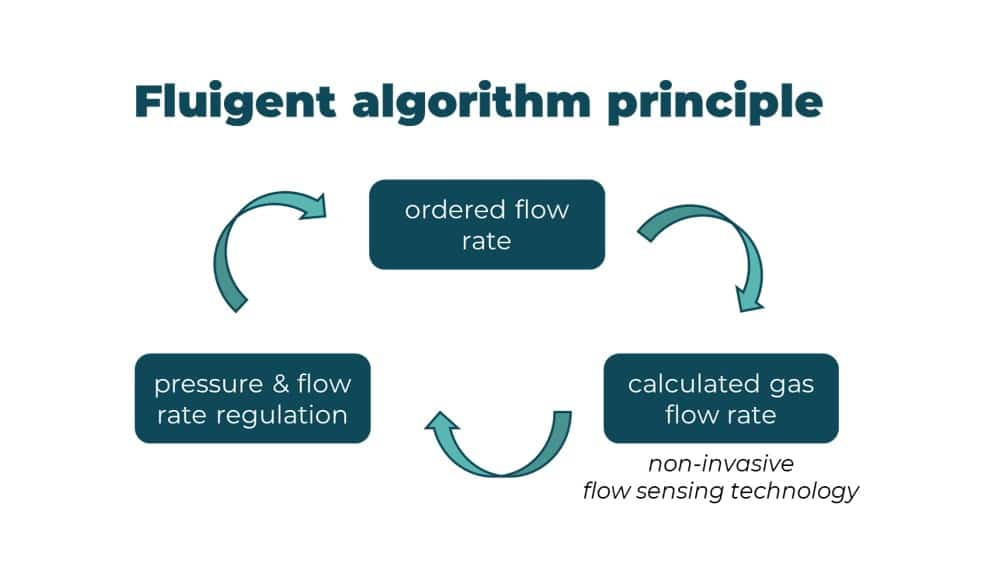

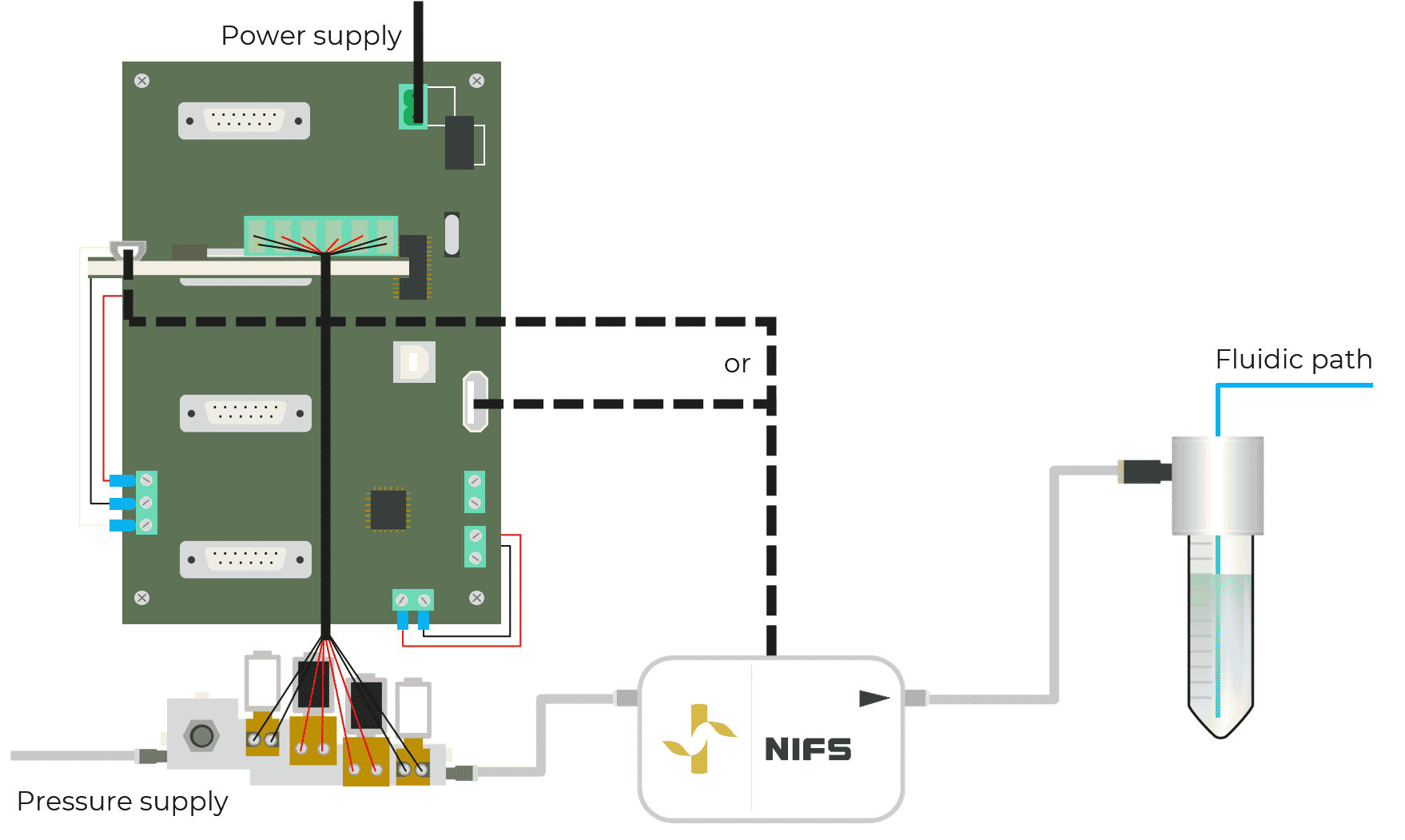

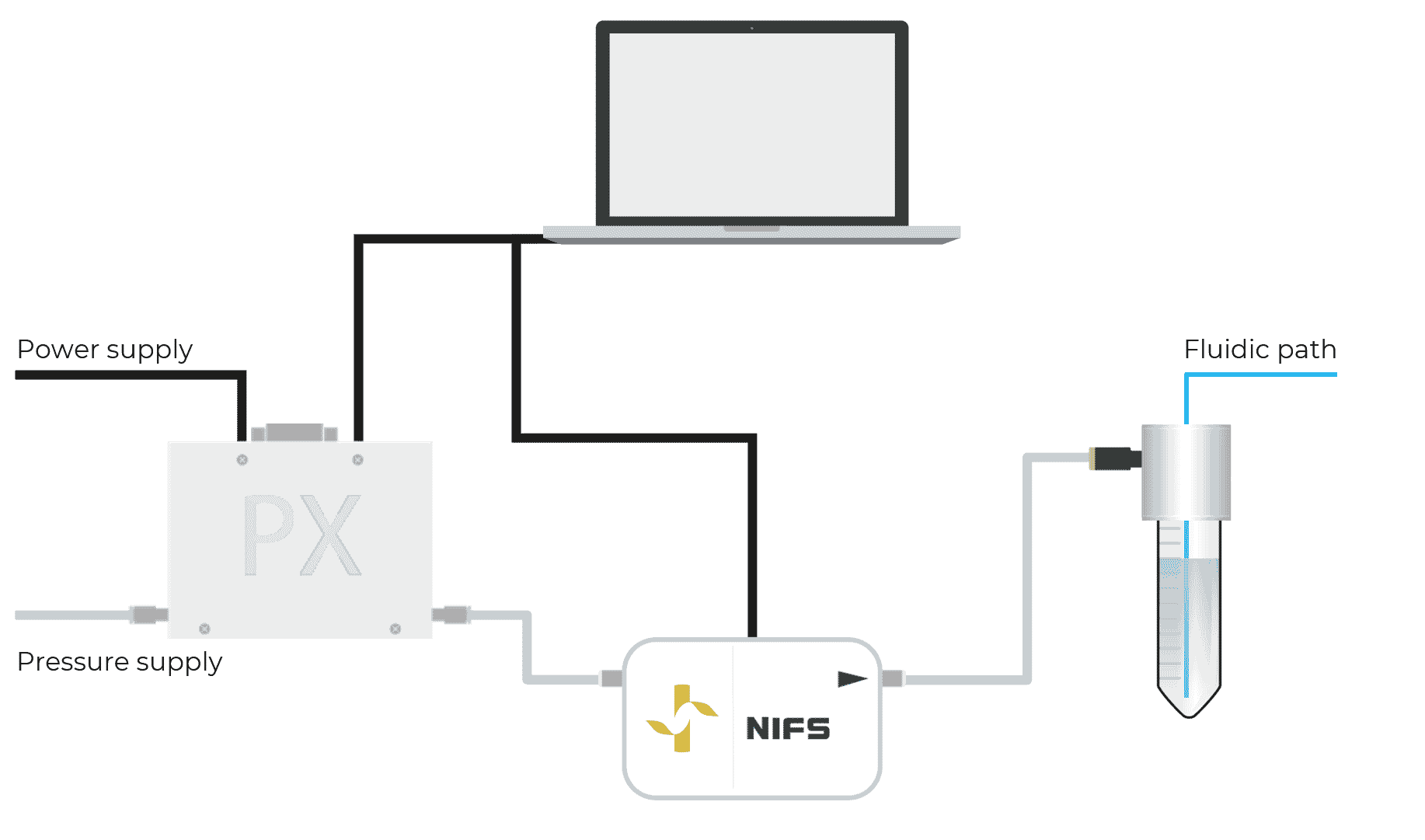

Thanks to Fluigent’s expertise, including “self-learning” algorithms and calibrations, our non-intrusive flow sensing technology determines the fluid flow rate from gas flow rate measurements. Using internally developed software, the input pressure is automatically adjusted by our pressure controller to monitor or control the liquid fluid flow rate in real-time.

The technology consists of a uniquely engineered assembly of sensing, pneumatic and electronic elements that allow for precise volumetric flow rate measurement. Thanks to the conception of a zero leakage (completely sealed) system, the gas flow rate is proportional to the fluid flow rate.

No contact with the fluidic path

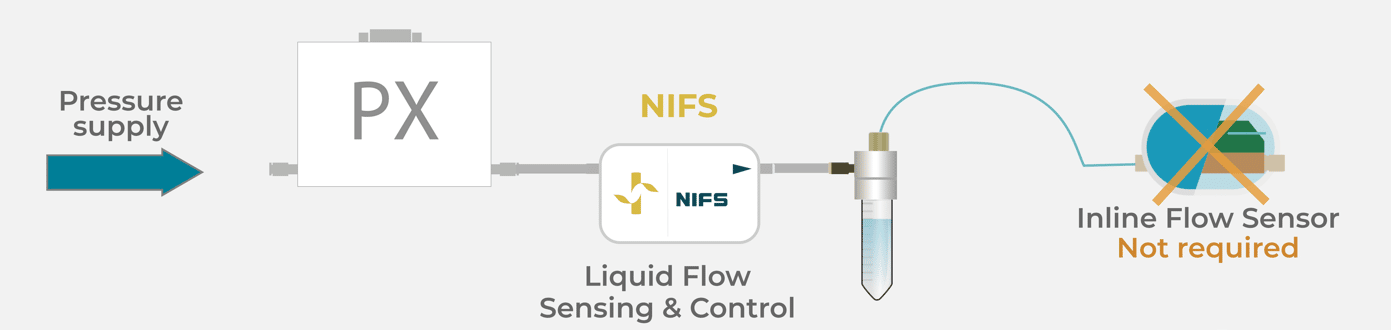

As described in figure 3, the technology is located at the pneumatic part of the system, between the regulated pressure controller and the fluidic reservoir (for more information about pressure-based flow control, see our expertise page). The flow sensing technology is never in contact with fluids.

No fluid-calibration needed

Traditional microfluidic flow sensing technologies are based on a calorimetric measurement principle and depend on fluid properties. They are generally calibrated for aqueous fluids, and additional calibrations need to be performed by the user. As explained above, with the new device, the fluid flow rate is determined by measuring the gas flow rate and is independent of the fluid properties (density, viscosity, surface tension, etc.). It makes this non-intrusive flow sensing technology universal and fluid calibration-free.

This is a technology of choice if one:

- Is working in a sterile/contamination-free environment

- Is working with several types of fluid: aqueous fluids (e.g. as water, media, PBS), blood, plasma, oils, surfactants, alcohols …

- Performs continuous operations with slow flow response time needs

A contamination-free flow sensing technology unlocking new features

PERFORMANCE

| Calibrated media | Air |

| Range | 100 μL/min to 10 mL/min |

| Accuracy | 5% reading |

| Lowest detectable flow increment | 5 μL/min |

| Response time | 10 s for reading 10 to 30 seconds for regulation (depends on the volume to control and the setup) |

HARDWARE SPECIFICATIONS

| Dimensions (L*W*H) | 99.85 x 45.00 x 33.50 mm |

| Weight | 117 g |

| Maximum pressure | 2 bar |

| Penumatic connector ports | 4 mm OD |

| Length of the electrical cable | 1 m |

COMPATIBILITY

| Products | FOEM: via micro-USB or via USB-A connected to computer POEM/PX: via USB-A connected to computer NOT COMPATIBLE WITH Flowboard OEM |

| Accessories | 2 mL reservoir + P-CAP screw 15 mL reservoir + P-CAP screw 50 mL reservoir + P-CAP screw |

| Product | NIFS | FS series |

| Invasiveness | Noninvasive: connected to the pneumatic path | Invasive: connected to the fluidic path |

| Calibration | Not required | Required for fluids with different viscosity than water |

| Flow rate range | 100 µL/min to 10 mL/min | 75 nL/min to 10 mL/min |

| Maximum pressure | 2 bar | 15 bar |

| Response time | 10 to 30 sec* | < 1 sec* |

| Flow stability | Excellent | Excellent |

| Recommended use | – Control of different liquid (no calibration/cleaning steps) – Long-term processes that risk contamination or clogging (non-intrusive) | – Manipulation of aqueous fluids only (no calibration step) – Processes with many flow rate changes (excellent response time and stability at low flow rates) |

*Depends on the volume to control and the setup

Applications of the non-invasive liquid handling system

Emerging applications make use of more complex fluidic operations and require compact systems. Our technology is fit for such applications as it is fully connected, compact, and provides excellent fluidic performance.

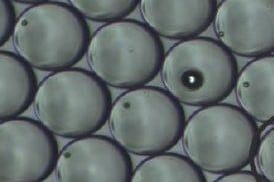

- Cell biology: biological applications such as cell culture under perfusion, immunostaining, organoid culture, organ-on-a-chip, drug discovery, single-cell analysis, cell cytometry and other applications that require a sterile environment. When using fluids such as culture media, PBS, buffers, blood, or plasma, every component in the fluidic path should be disposable, or able to be sterilized. Fluigent’s new non-intrusive flow sensing technology is ideal for such applications as it is not in contact with the fluids in play.

- Microfluidic droplet generation: When generating droplets, several types of fluids with different properties are used (aqueous solutions, oil, surfactants, alcohols). Using traditional flow sensing technology requires fluid calibration to be performed for every fluid. This step should be repeated periodically as fluid properties can differ from one batch to another. Inaccurate calibration affects the flow rate and the size of the droplets. The new sensing technology is ideal as no fluid calibration step is required, allowing one to precisely control flow rate for all types of liquids.

- (bio)chemical and molecular analysis: Chemical and molecular components can be screened using droplet microfluidic technology for drug, enzyme, or food analysis. The advantages of using this non-intrusive flow sensing technology are listed above.

- Quality monitoring and system failure prevention: flow sensors monitor fluidic protocol in real-time and warn the user of unexpected flow rate fluctuations.