Microfluidic knowledge

From idea to production

Fully Custom Microfluidic Device

- Fluigent expertise

- Flexible

We adapt to your specifications needs

- Cost-efficient

Cost-effective devices

Bring the vision of your device to life.

Whether you’re a start-up or a larger organization, Fluigent can drive your microfluidic project from conception to design and manufacturing. By partnering with us, customers benefit from Fluigent’s portfolio of products, technologies, patents, and more than 15 years of experience with microfluidic technology. We combine our expertise and knowledge to design and manufacture the highest quality custom microfluidic devices. Partner with Fluigent to accelerate your product time to market.

Fluigent has OEM partnerships with several brands in various fields.

What our customers say

“Fluigent’s expertise enabled us to completely change the scale of our microfluidic protocols, from the Ph.D. student experiment to the fully automated and parallelized workflow available for anyone. In addition to accompanying us in this process with their ideas and multi-disciplinary skills, Fluigent’s support and responsiveness are first class!”

Anonymous customer

From development to commercialization: a long-term partnership

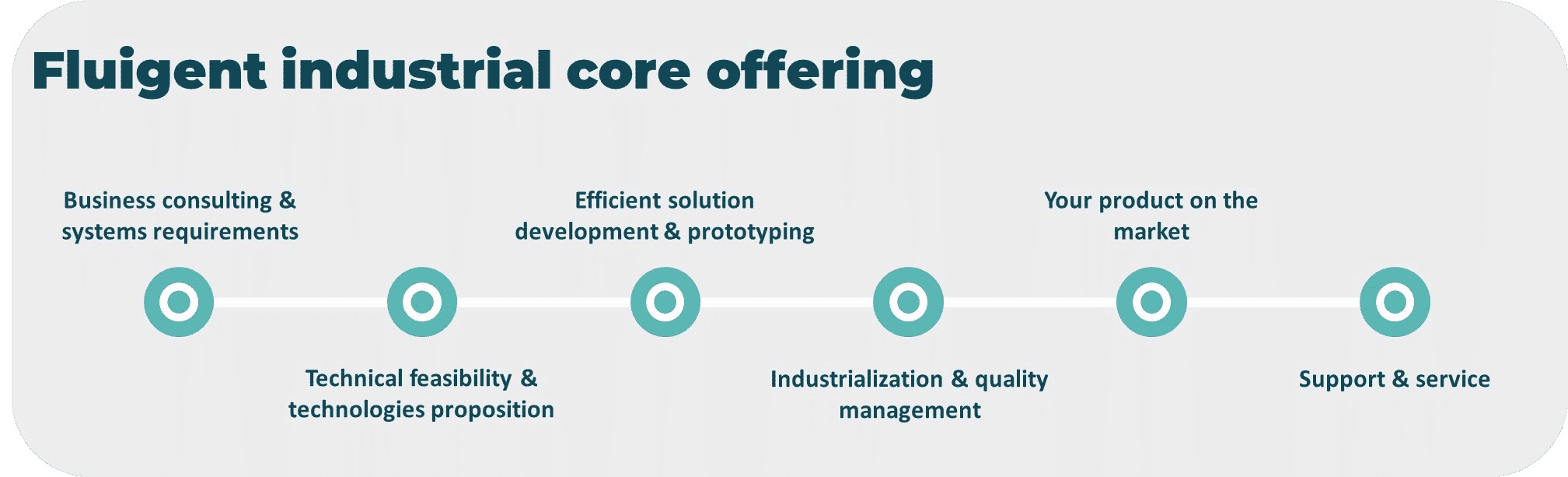

Each system has unique specifications. Fluigent offers flexible, custom microfluidic device development to provide the system you envision. Our core offering includes complete OEM microfluidic services to bring your solution to market while ensuring high-quality standards and satisfaction.

1. Understanding customer needs

Fluigent discusses all users, business models, and technical specifications for your microfluidic product development. To understand your specific challenges and be sure to achieve your objectives, concept development is discussed.

2. Technical feasibility

After identifying your needs and technical specifications, our R&D team will evaluate the technical feasibility of the project. We will then propose the most cost-efficient solution based on our state-of-the-art modules and unique portfolio of innovative technologies to empower your application. The system requirements are set to take your project from concept to reality.

3. Solution development & Prototyping

Once the specifications and requirements are fixed, an R&D project team will be dedicated to the development of your custom microfluidic solution. Throughout the development, we will continuously update you on the project’s overall progress. Transparency is an essential value for us. The OEM microfluidic custom system prototype will be sent to you for testing and validation.

4. Industrialization & Quality Management

After validation, our R&D will transfer your prototype to our production department. Through training, production files, bench tests, and other quality assessments driven by our ISO 9001 certificate, we deliver a standard system with highly reproducible performance. We developed effective systems to meet industry standards. Our processes are constantly tested for continual improvement and trackability. We are confident in the quality of the device that will be delivered.

5. Support and Service

Our partnership for does not end once your product is commercialized. After we build and ship your custom microfluidic device, Fluigent will provide first-class support including team training and spare part orders. Support training is customized to your specific needs.

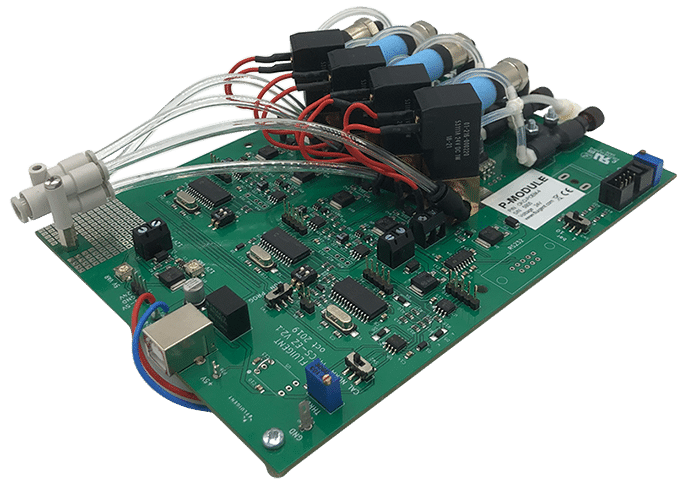

Fluigent’s unique portfolio of technologies

With more than 15 years of experience, Fluigent was the first company to use pressure to move fluids for microfluidics to face fluid stability and sterility challenges. Thanks to a continuous innovation process, we tackle current limitations with developing cutting-edge technologies and currently own more than 20 patents. Our knowledge in electronics, mechanics, pneumatics, software, and fluidics engineering provides efficient solutions in response to current market needs. By integrating our technologies into your custom microfluidic device, Fluigent will empower your application and offer you a true advantage over your competitors.

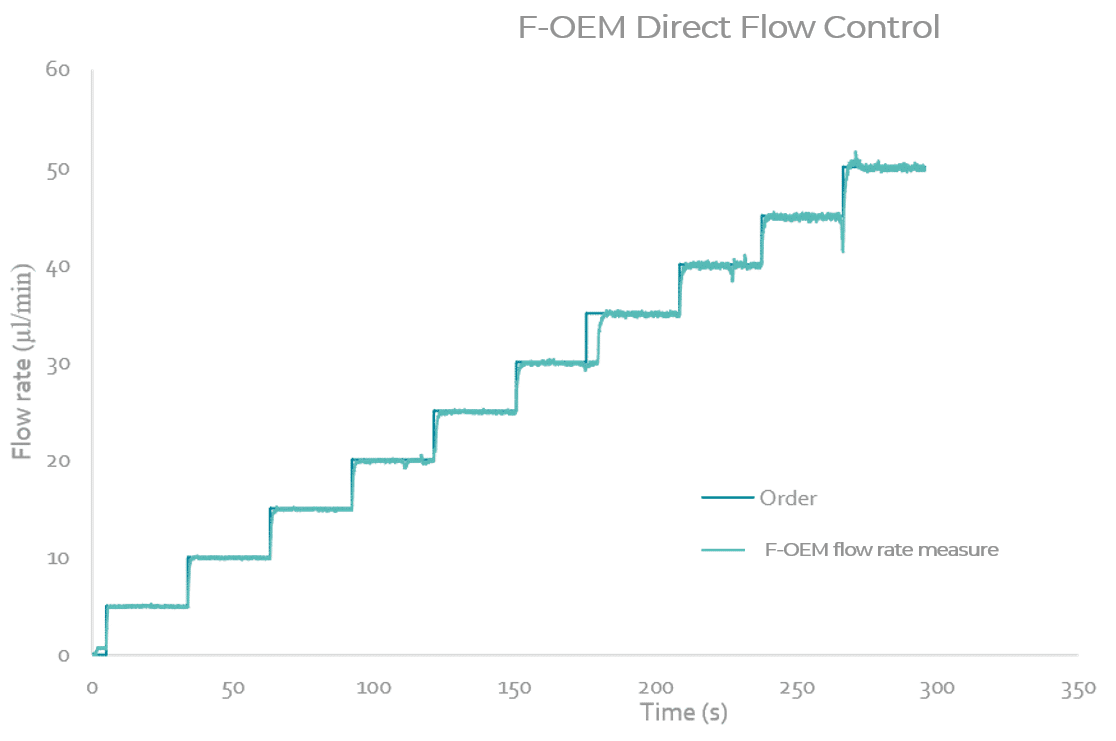

DFC Flow Rate Control Algorithm

Self-learning algorithm allowing live pressure and/or flow-rate monitoring and control

Compact All-in-One Micropumps

Fluigent algorithm in micropumps for compact pressure supply and control

Fluid Stirring

Dispersion modules: orbital shaker, vortex mixer and magnetic stirrer

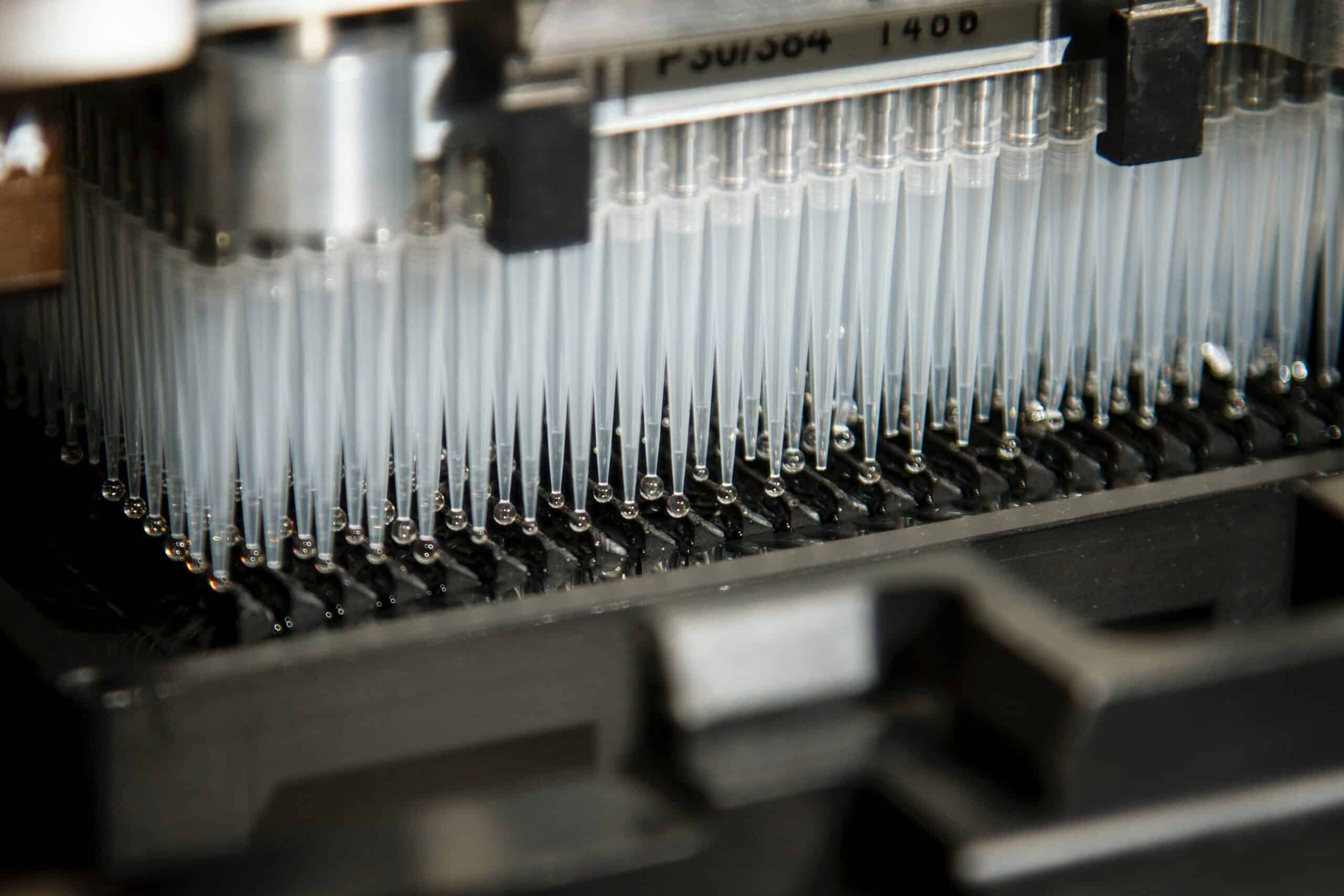

Robotic pipetting

3 dimensions robotic stage for fluid sampling into microwells

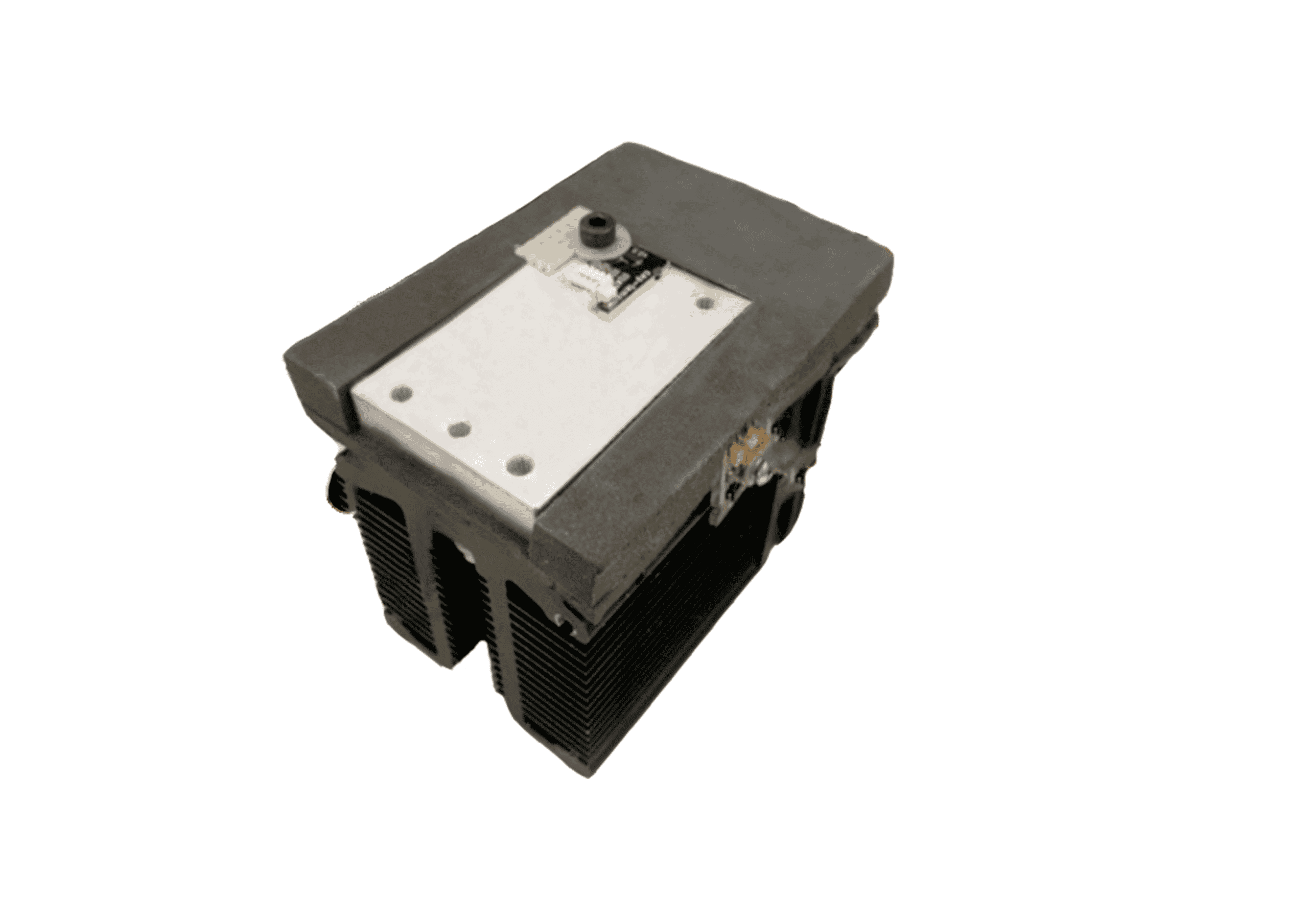

Temperature management

Temperature modules for heating and cooling

And many more…

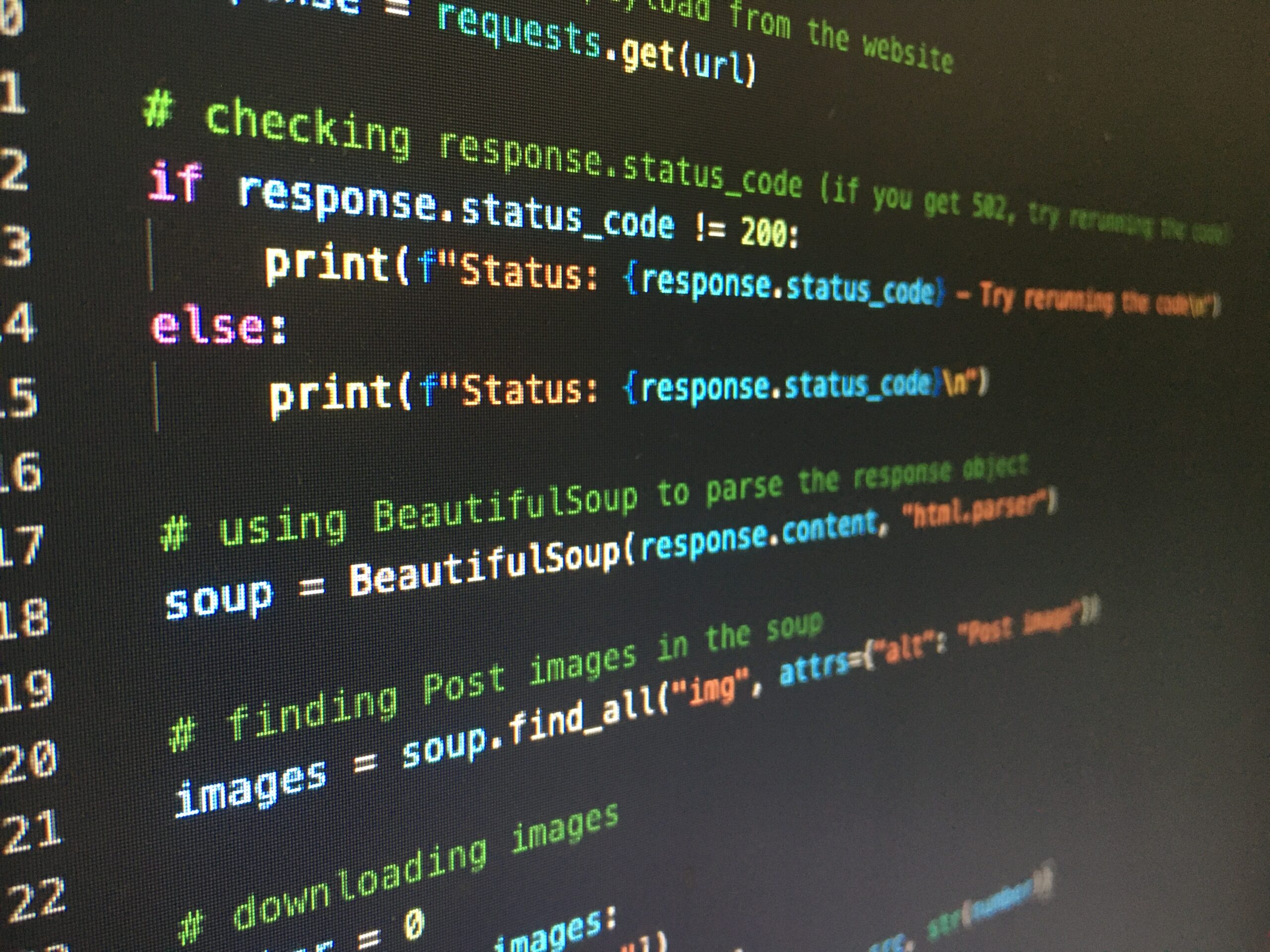

Custom software development

We provide custom software based on our well-known end-user software OxyGEN as well as on our SDK library for your custom microfluidic device. We develop and design your user interface and create dedicated protocols to best suit your application. In addition, we can interface with software from third-party devices during your microfluidic product development to allow cross-communication and guarantee the best efficiency and user-friendliness.

Our portfolio of techniques

Fluigent’s range of technologies can bring our microfluidic expertise to various fields.

Optical microscopy

OEM solutions for customed perfusion system or any flow management system dedicated to an end-to-end workflow.

Laboratory automation

Liquid handling solutions for sample preparation and dilution for our OEM partners.

Drug discovery

Fully automated workflows allowing for sequential injection, fluid recirculation, or microfluidic droplet generation.

Diagnostic

Multiple sampling and automated workflow for diagnostic devices.

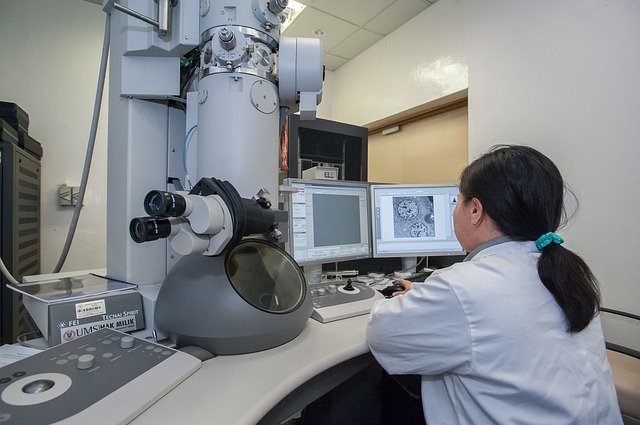

Electron microscopy

Flow control for biological observations in controlled flow conditions.

Spectroscopy

Automated flow control for in-situ monitoring or sample preparation.

Mass spectrometry

Online sampling for real-time analysis or sample preparation including filtration and dilution.

Cell and gene therapy

Automated workflow applied to medical needs.

Cosmetic

Flow control for testing and screening active ingredients.

Quality control

Customed calibration devices for the quality control of your machines.

A trusted partner for your microfluidic OEM system

Over the past 10 years, we’ve provided more than 1, 500 microfluidic OEM modules and systems to businesses worldwide. Our R&D team represents more than 30% of the company, leading us to earning more than 20 patents.

65

OEM/Industrial customers around the world

20

Patents put us at the forefront of innovation

15

Different fully integrated OEM systems developped

1500+

OEM systems and components delivered

10

Years of experience in OEM lab automation

OEM customer case studies

Each customer is different and has specific challenges, and we take particular care to address them. Discover the story of our customers and the relationship we build with them in our customer case studies.

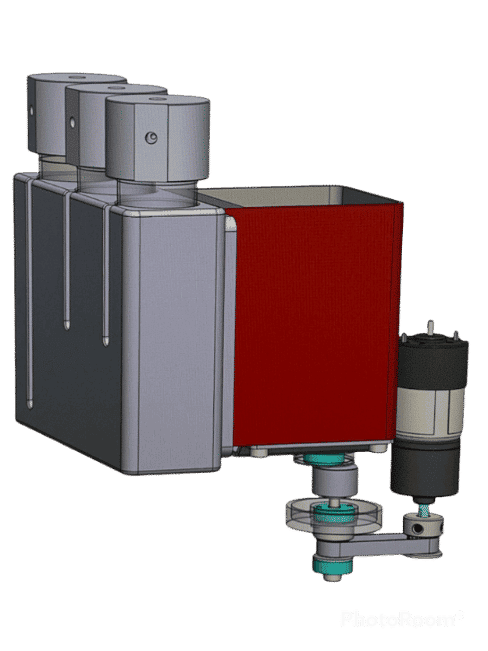

Context

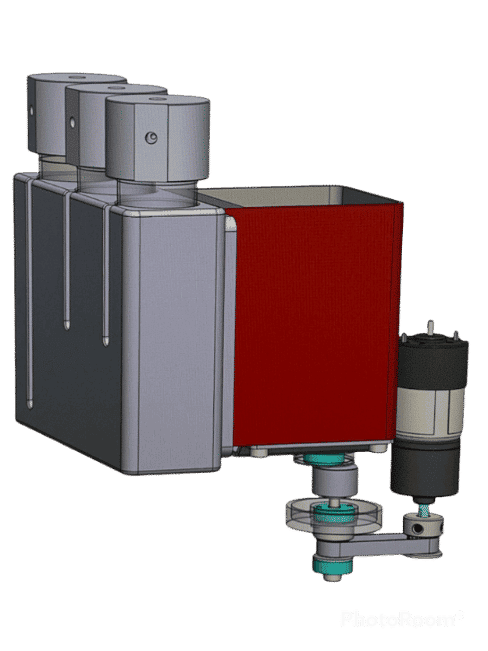

A leading electron microscopy group wanted to add an automatic sampling system to their standard imaging platforms as a value-added feature for their customers. Fluigent was approached to develop this complementary module due to our vast experience in engineering and manufacturing OEM microfluidic custom system.

Solution

Fluigent’s expertise in custom microfluidics and fluid handling hardware &software provides technical support for all user experiments.

Result

The sampling system automates sample volume delivery over lengthy imaging experiments while keeping the samples refrigerated. Shortly, additional functionality will also be integrated into the client’s software so the user can fully benefit from the whole platform in one place.

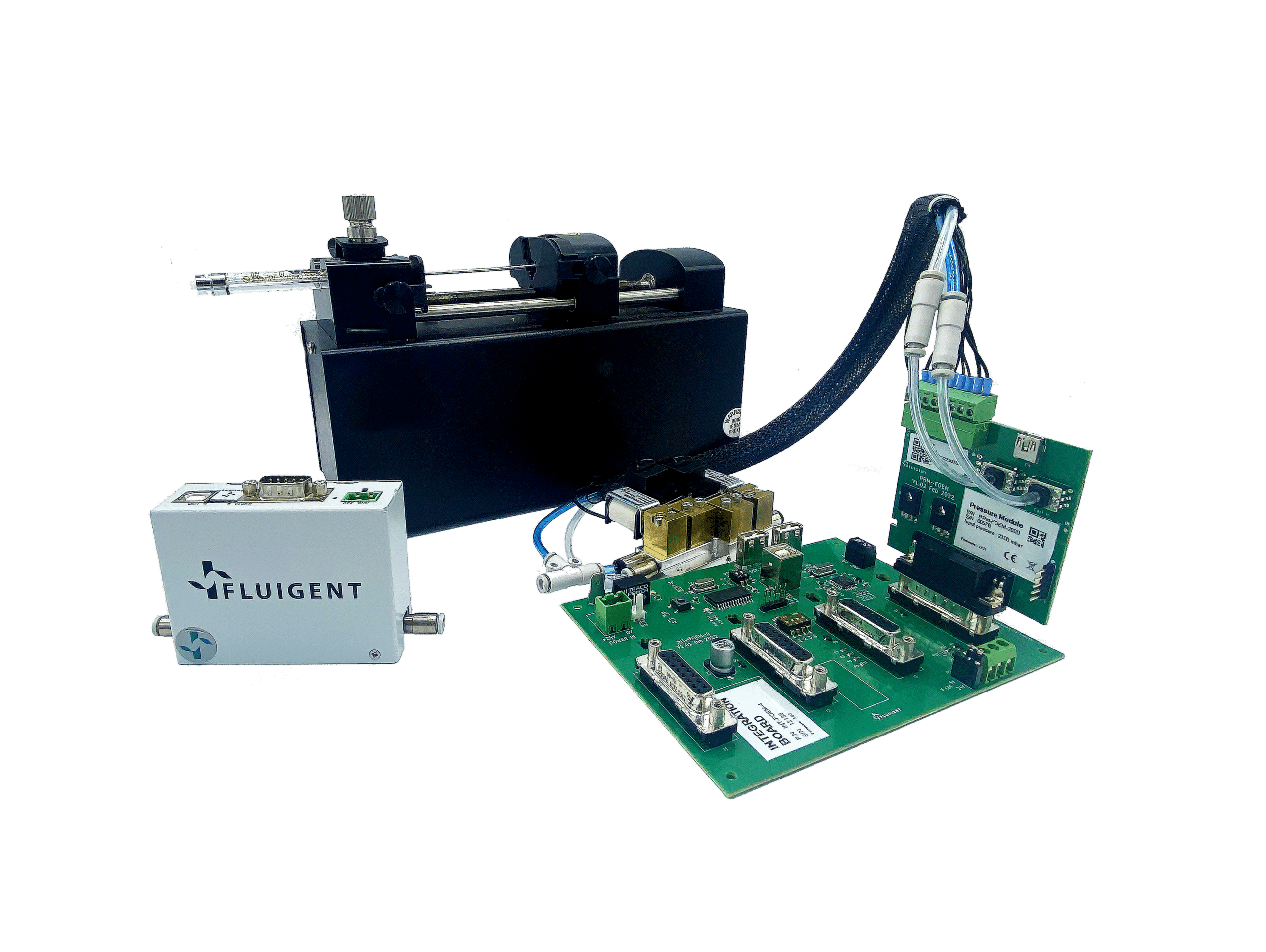

Context

This company approached Fluigent for a fluid handling solution after researching microfluidic technology.

Solution

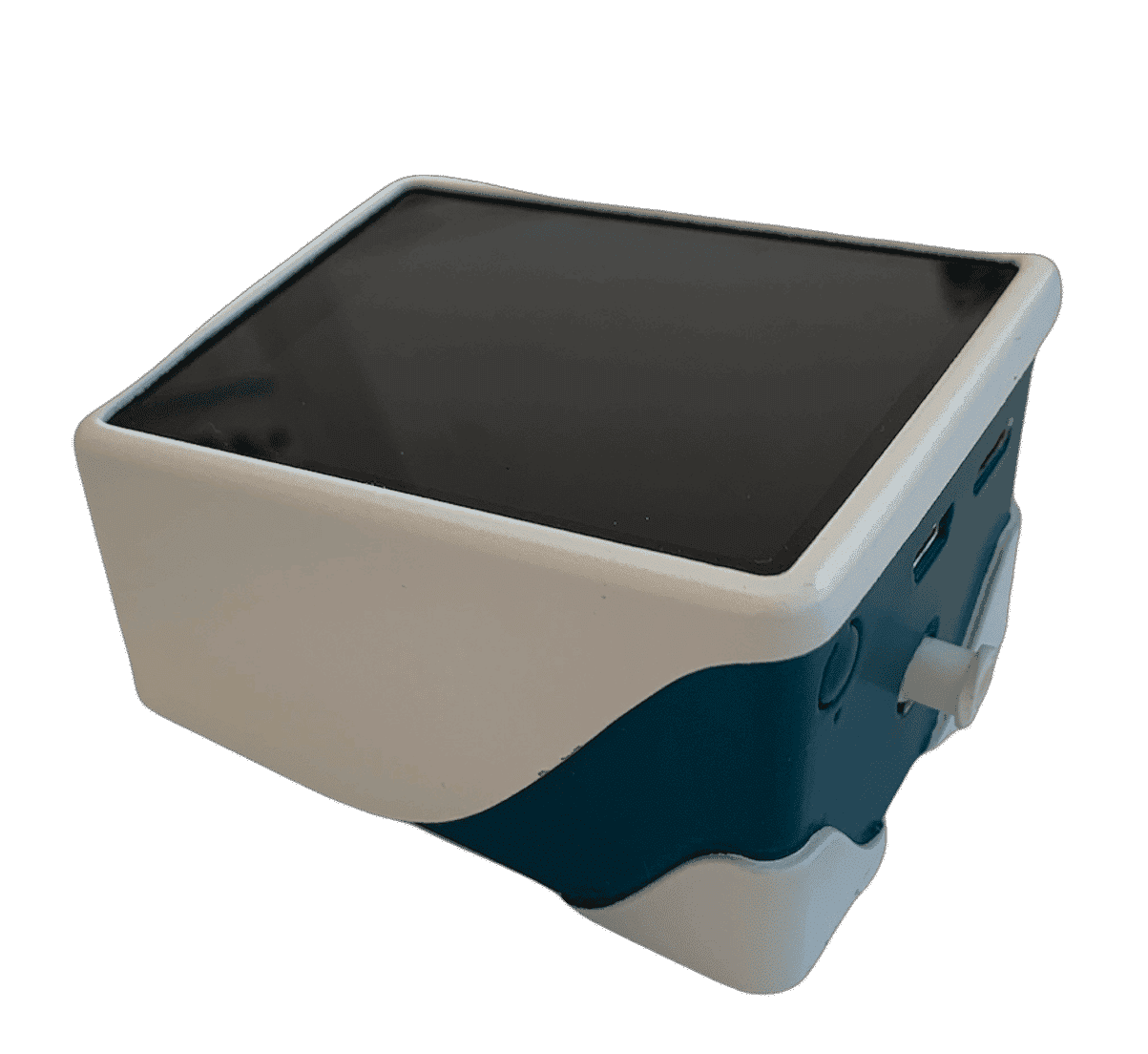

While the client was focusing on developing their proprietary technology in biology, Fluigent’s team managed to create the components needed surrounding the chips, from the fluidic system to the instrument’s design.

Result

This result enables users to use multiple microfluidic devices at the same time with minimum prior training, providing an in vitro diagnostic test of precision medicine.

Expertise & resources

-

Microfluidics case studies OEM Case Study: Microfluidic Drug Screening Read more

-

Expert Reviews: Basics of Microfluidics Key reliability indicators for OEM components to ensure long-term performance of your flow control system Read more

-

Microfluidic Application Notes Peristaltic Pump vs Pressure-Based Microfluidic Flow Control for Organ on Chip applications Read more

-

Expert Reviews: Basics of Microfluidics Flow control for droplet generation using syringe pumps and pressure-based flow controllers Read more

-

Expert Reviews: Basics of Microfluidics Extended Capabilities of Pressure Driven Flow for Microfluidic Applications Read more

OEM microfluidic technologies

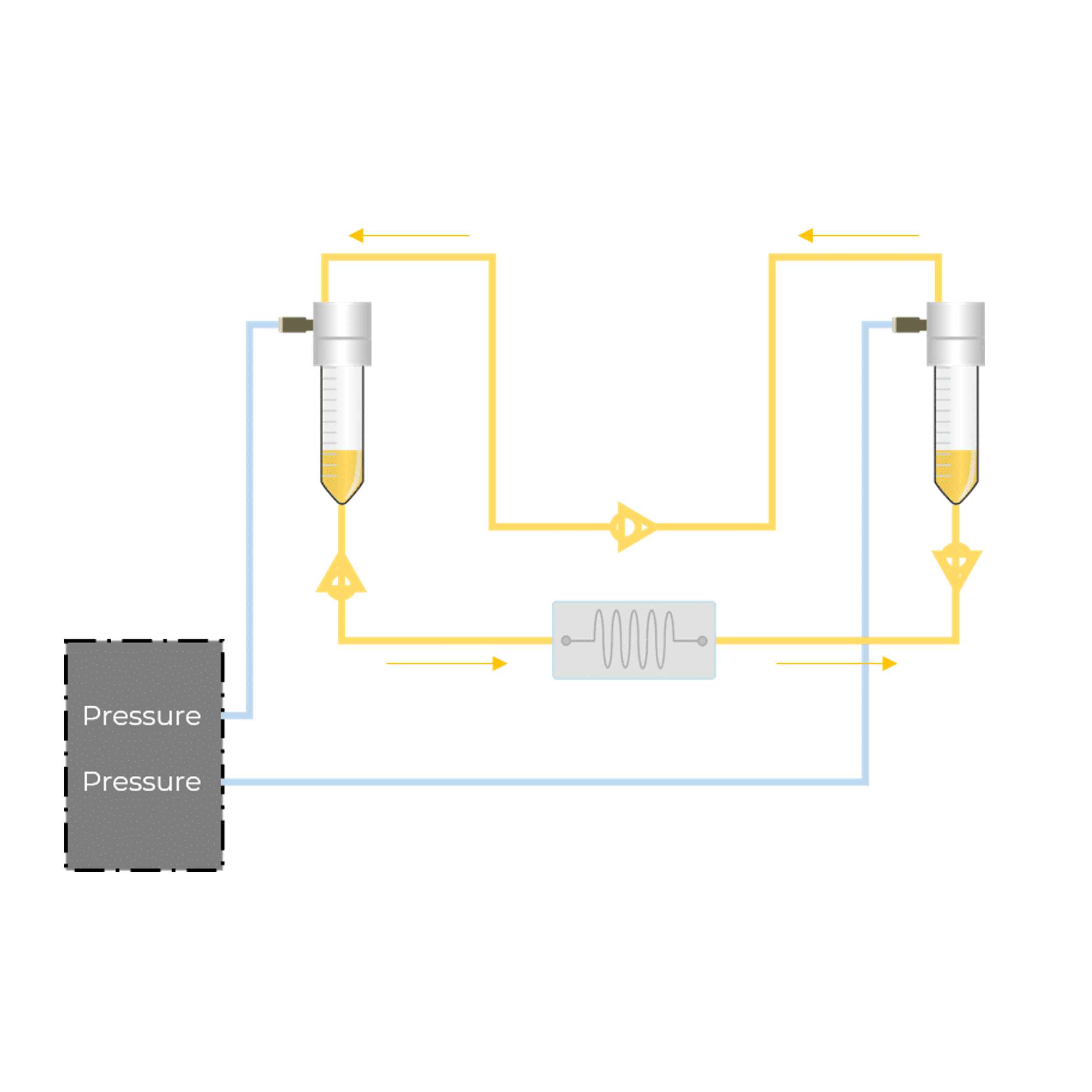

Microfluidic recirculation system

Read more

Liquid Stirring Solutions

Read more

5 reasons to choose OEM pressure controllers over OEM syringe pumps for microfluidic applications

Read more

Microfluidic Temperature Control module

Read more

Compact All-In-One Microfluidic Micropump

Read more

DFC, “Self-Learning” Microfluidic Flow Control Algorithm

Read more

Related products

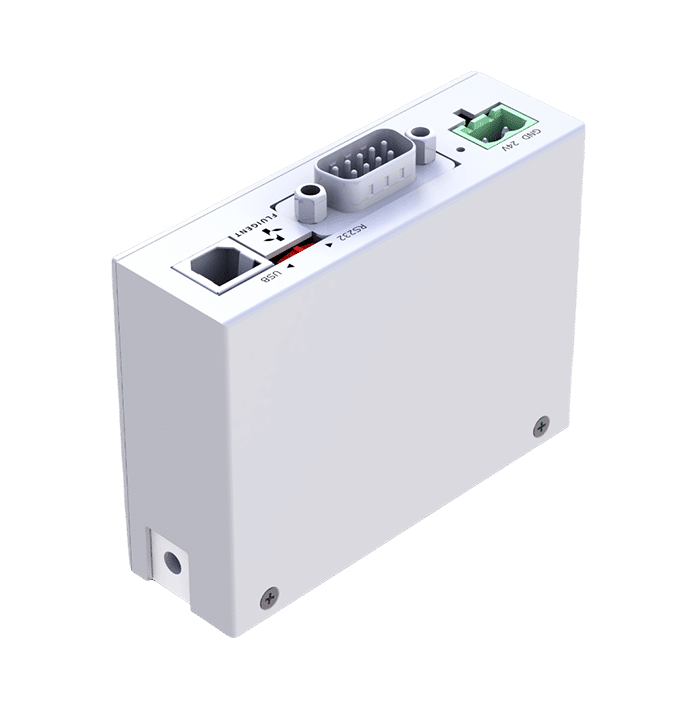

Microfluidic Flow Management Unit

P-OEM

See the offer

Microfluidic OEM Pressure Controller

OEM Fluigent PX

See the offer

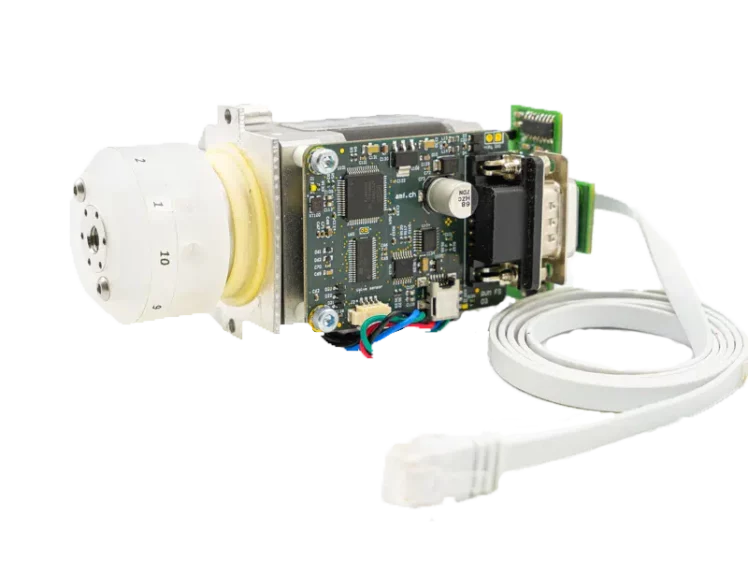

Rotary multi-port microfluidic valve for industry

OEM microfluidic electric rotary valve with multi-port (Fluigent M-X)

See the offer

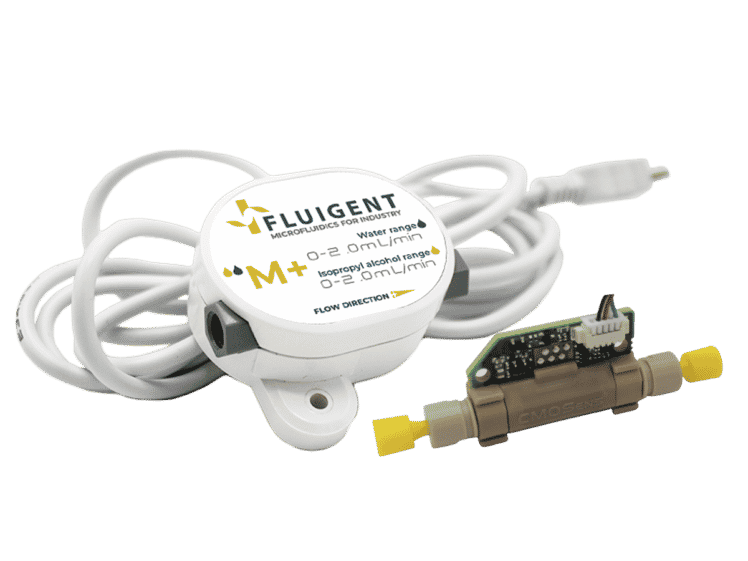

Microfluidic OEM Flow Sensor

FS Series

See the offer