Microfluidics overview: History and Definition

Discover the fascinating history and evolution of microfluidic technology and how it has revolutionized various fields, from biology and medicine to industry, and applications ranging from droplet generation to life science.

Microfluidics is the science of manipulating and controlling fluids, usually in the range of microliters (10-6) to picolitres (10-12), in networks of channels with dimensions from tens to hundreds of micrometers. Learn how these microminiaturized systems have paved the way for groundbreaking advancements in drug delivery, diagnostics, and lab-on-a-chip devices.

In this microfluidics overview, we will offer a glimpse into this revolutionary domain to enhance your understanding of precise fluid handling and the limitless possibilities it unlocks in the world of scientific exploration.

What is microfluidics?

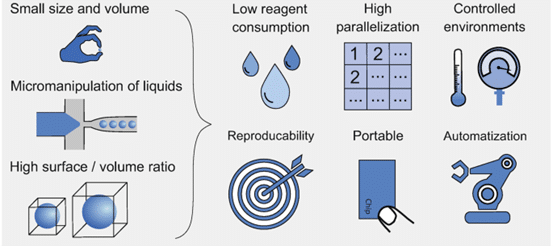

Microfluidics is a field at the intersection of physics, engineering, and biology that has evolved over several decades. Microfluidics is both the science that studies the behavior of fluids flowing through micro-channels, and the technology of systems that process or manipulate small (10-6 to 10-12 L) amounts of fluids using microminiaturized devices containing chambers and channels through which fluids flow or are confined.

This discipline has been growing exponentially since the 1990s, and is viewed as an essential tool for life science research or biotechnologies more generally. It is a very attractive technology for both academic researchers and industrial groups because it considerably decreases sample and reagent consumption, shortens experiment times, and reduces the overall costs of applications.

Working principle of microfluidics

Microfluidics deals with very precise fluid control usings small volumes and spaces, with the “micro” prefix referring to one or more of the following features:

- Small volumes (µL, nL, pL, fL)

- Small size (mm, µm)

Microfluidic chips are the devices used in microfluidic studies in which microchannels have been molded or patterned. The microchannels are connected to allow fluids to pass through different channels, moving from one location to another.

Active microfluidics refers to fluid handling performed by active components such as microfluidic pumps or microfluidic valves. Microfluidic pumps, such as pressure-driven controllers, peristaltic or syringe pumps, supply fluids in a continuous way or are used for dosing, whereas microfluidic valves can inject precise volumes of sample or buffer.

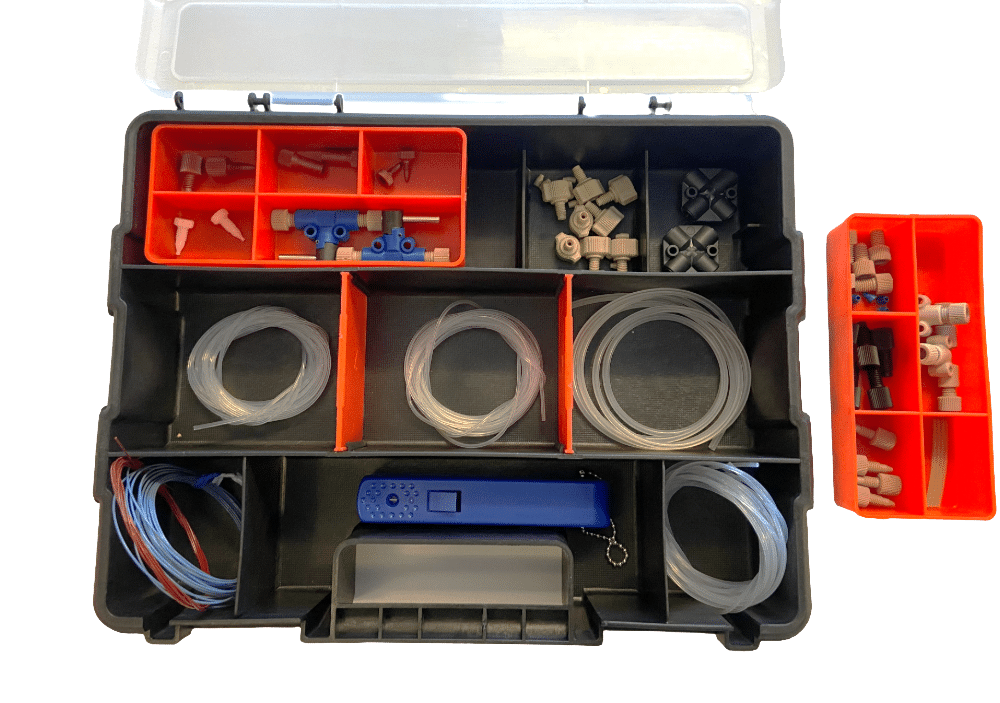

Components of a microfluidic setup

A microfluidic system typically consists of various components designed to manipulate and control the flow of fluids on a microscale. Here are some common components found in microfluidic systems:

- Microchannels: Small, intricate pathways on a chip through which fluids flow. These channels are often fabricated using microfabrication techniques like photolithography.

- Reservoirs: The points where fluids are loaded into or collected from the microfluidic system. They act as source and sink locations for the liquids being manipulated.

- Microfluidic valves: They regulate the flow of fluids within microfluidic channels. They can be passive (relying on the geometry of the channels) or active (electronically controlled). Valves are crucial for directing and stopping fluid flow as needed.

- Microfluidic pumps: They generate pressure or flow to drive the movement of fluids through the microchannels. Various types of pumps, including syringe pumps or peristaltic pumps, may be integrated into microfluidic systems.

- Sensors: Optical or electrochemical sensors are integrated to detect and analyze the properties of the fluids, allowing for real-time monitoring and feedback.

- Detectors: They identify specific signals or changes in the fluids. Common detectors include photodetectors for optical analyses or electrodes for electrochemical sensing.

- Microfluidic chip: The microfluidic chip itself is a key component, acting as the physical platform on which all the channels, valves, and other elements are integrated. It is often made from materials like glass or polymers.

- Software and control system: Used to program and monitor the operation of the microfluidic system. It controls the various components, such as pumps and valves, to execute specific fluidic processes.

Some systems have additional components such as mixers, microvalves, detectors, temperature controllers, etc. These components work in harmony to create a microfluidic system capable of performing a wide range of tasks, from chemical analyses and synthesis to biological studies and diagnostics.

WEBINAR REPLAY – Overview of Microfluidics

This webinar aims to provide a broad introduction to microfluidics and related physical principles. The webinar will also feature some typical applications in microfluidics.

What you will learn:

- Introduction to microfluidics: Definitions and terminology, history and areas of application.

- Overview of common microfluidic systems:

- Microfluidic chips

- Microfluidic flow controllers

- Physical principles related to microfluidics:

- Laminar flow

- Diffusion in microfluidics and how to control mixing

- Droplet microfluidics:

- Definitions and related physics

- Droplet chip designs and droplet generation regimes

- Surfactants in droplet microfluidics

Webinar Replay – LineUp Series, the new generation of microfluidic controllers

Discover the LineUp™ Series, Fluigent’s leading fluidic delivery platform.

A complete solution, including software for automation, to easily adapt to any microfluidic setup and provide unmatched accuracy, simplicity, and versatility.

What will be covered?

Introduction to microfluidic systems and pressure-based flow controller.

Discover Fluigent’s revolutionary pressure-based systems

A complete overview of the LineUp™ series features and capabilities

Why you should attend:

Challenge your current microfluidic setup with Fluigent revolutionary solutions

Discover unsuspected features and modules of the LineUp series and its future developments

You are developing a new microfluidic experiment and wonder how Fluigent solutions can help you

Advantages and Key Principles of Microfluidics

Microfluidics is a very attractive technology offering an array of advantages for both academic researchers and industrial groups

At a micrometric scale, the behavior of fluids changes and presents several advantages: rapid heat transfer, an increased surface-to-volume ratio, laminar flow, and possible diffusive mixing. In addition, microfluidics considerably decreases sample and reagent consumption, shortens experiment times, and reduces the overall costs of applications.

The overall result is a significant increase in efficiency, driving a substantial reduction in both resource usage and overall application costs.

Microfluidics for Miniaturized Laboratories

A key concept related to microfluidics is the ability to integrate operations that would typically require a whole laboratory into a simple micro-sized system. Currently, a traditional scale-up is substituted in microfluidic systems by multiplexing, drawing on the compact size of the device to dramatically shorten the time from formulation to production. This leads to the adoption of microfluidic technologies not only for analytical purposes but also for large-scale manufacturing in process industries, particularly nanomedicine, fine chemistry, and the food, environmental, and pharmaceutical industries. [1]

Through the dynamic field of microfluidics, a new era of possibilities unfolds.

- Experimental accuracy: Microfluidics empowers researchers to refine and elevate the precision of scientific challenges, pushing the boundaries of detection to new lows and unraveling insights at the molecular level that were once unimaginable.

- High efficiency: Microfluidics allows for parallelized analyses, unlocking the ability to run multiple experiments simultaneously to achieve remarkable results with unparalleled efficiency.

- Cost reduction: Microfluidics offers a gateway to cost reduction without compromising the quality of the work.

- Time reduction: Often the most precious commodity in research, time becomes a valuable ally with microfluidics and its potential to accelerate the pace of discovery by significantly shortening experimental timelines.

- Precision meets practicality: Microfluidics is reshaping the landscape of research and industry where efficiency becomes the hallmark of progress. It has limitless possibilities and applications in various fields.

Precise control and automation

Microfluidic systems also offer excellent data quality and improved parameter control, allowing for process automation while maintaining high performance. They have the ability to both process and analyze samples with only minor sample handling. The microfluidic chip is combined with a fluid handling system to achieve incorporated automation that allows users to generate multi-step reactions requiring a low level of expertise and a wide range of functionalities.

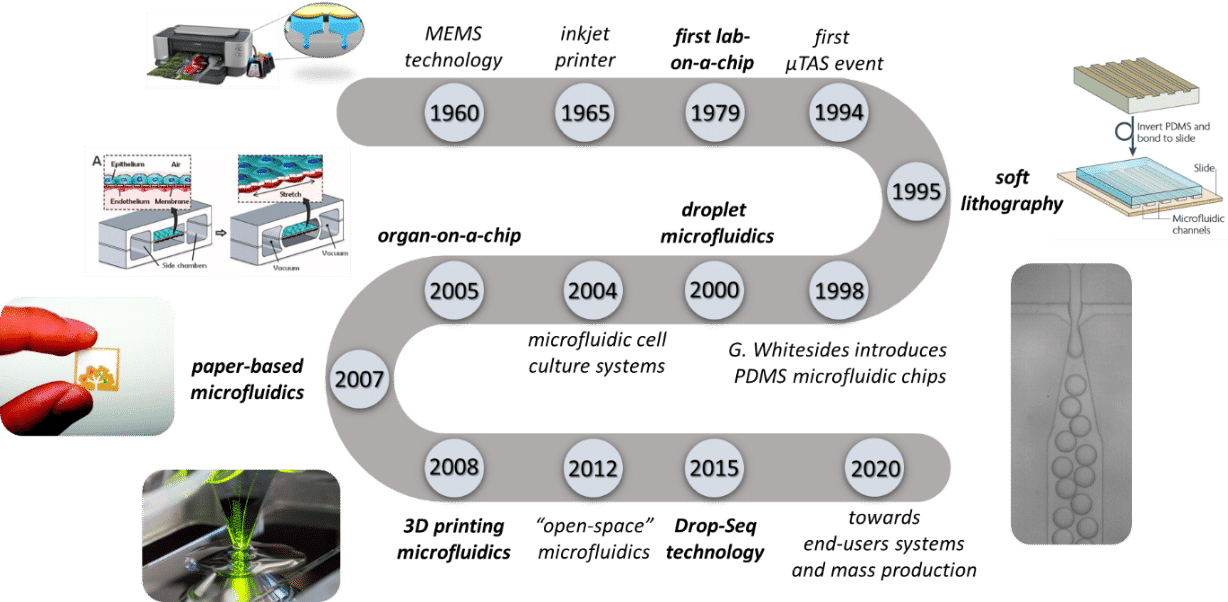

Origins of microfluidics, a fluid handling system for printers

The history of microfluidics dates to the 1950s, principally in inkjet printer manufacturing. The mechanism behind these printers is based on microfluidics, and involves the use of very small tubes carrying the ink for printing.

In the 1970s, a miniaturized gas chromatograph was constructed on a silicon wafer. By the end of the 1980s, the first microvalves and micropumps based on silicon micro-machining had also been presented. In the following years, several silicon-based analysis systems were presented.

All of these examples represent microfluidic systems, since they enable the precise control of decreasing fluid volumes on one hand, and involve miniaturization of fluid handling systems on the other.

A major contribution in this field has been the development of soft lithography in a fast prototyping polymer, polydimethylsiloxane (PDMS), as a method for fabricating prototype devices and testing new ideas.

The expansion of microfluidics and development of microfluidic components

In the 1990s, advancements in microfabrication technologies expanded the possibilities of microfluidic systems. Researchers began designing lab-on-a-chip devices for applications ranging from chemical analysis to medical diagnostics. This era saw the emergence of the first microfluidic devices with integrated sensors and valves.

As the 21st century unfolded, microfluidics experienced a surge in popularity. The technology found applications in genomics, proteomics, drug discovery, and point-of-care diagnostics. Researchers explored the potential of organ-on-chip models, replicating human physiological conditions for more accurate testing.

Today, microfluidics continues to push boundaries, with ongoing research focusing on enhancing precision, scalability, and integration with other scientific disciplines.

Over the years, researchers spent a lot of time developing new microfluidic components for fluid transport, fluid metering, fluid mixing, valving, or concentration and separation of molecules within miniaturized quantities of fluids.

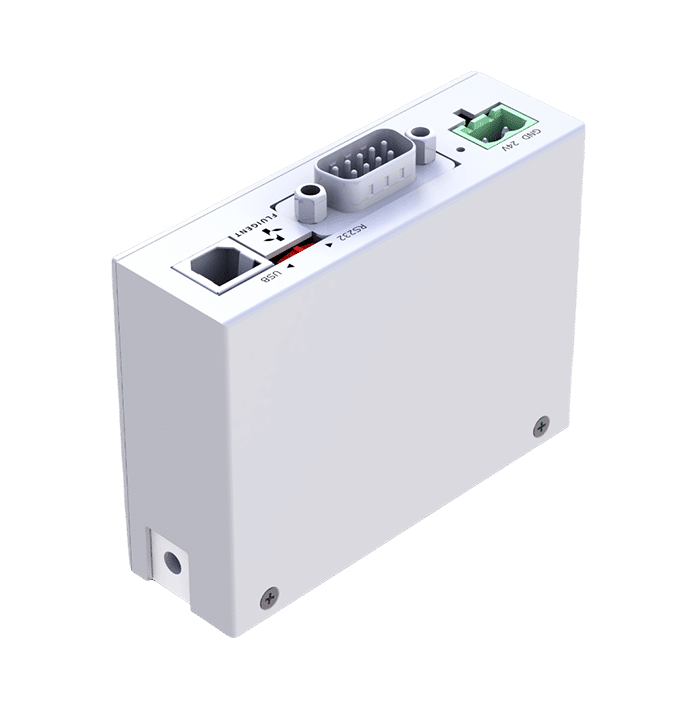

In 2006, for example, Fluigent was the first company to introduce a disruptive new way of handling fluids in microfluidics: microfluidic pressure pumps.

The use of a pressure-based pump instead of a syringe pump allows for very rapid response times and pulseless flow. At first, these pumps could only control the pressure of liquids in microfluidic chips, but later, by adding a flow sensor and a unique feedback control loop, Fluigent enabled control of both pressure and flow rate. The precise control of fluids in a microfluidic device allows for sophisticated new applications which were not possible before.

Recently, an increasing number of microfluidic-based devices, developed by both small start-ups and large pharmaceutical and biomedical companies, have been released and are entering the market.

Comparative example: Why choose a microfluidic device instead of a robot?

Due to the low volumes required, microfluidic technologies represent a promising alternative to conventional laboratory techniques. They allow for complete laboratory protocols on a single chip of a few square centimeters. Table 1 shows the main advantages of using microfluidics instead of conventional laboratory assays for a given experiment (ultra-high throughput screening of a typical enzyme).

| Robot | Microfluidic droplets | |

|---|---|---|

| Total reactions | 5 × 107 | 5 × 107 |

| Reaction volume | 100 µL | 6 pL |

| Total volume | 5,000 L | 150 µL |

| Reactions/day | 73,000 | 1 × 108 |

| Total time | 2 years | 7 hours |

| Number of plates/device | 260,000 | 2 |

| Cost of plates/device | $ 520,000 | $1.00 |

| Cost of tips | $10 millions | $0.30 |

| Amortized cost of instruments | $ 280,000 | $1.70 |

| Substrate | $4.75 million | $0.25 |

| Total cost | $15.81 million | $2.50 |

Table: Comparison using traditional methods and in microfluidic emulsions. Adapted with permission from Agresti J. J. et al, Ultrahigh-throughput screening in drop-based microfluidics for directed evolution, PNAS 2010, 107:4004-4009. Copyright 2010 National Academy of Sciences, U.S.A [3]

To better appreciate the impact of microfluidics, we can draw an analogy with the evolution of computers. In the 1960s, an entire room was needed to run a computer. Since then, every component has been reduced in size, and laptop products have appeared. Now a simple smartphone is more powerful than any computer built before, leading to reduced prices and a much more user-friendly experience. It’s the same with microfluidics!

Overview of microfluidics applications

Microfluidics is an attractive technology for multiple fields.

Microfluidics extends its capabilities in precise liquid injection to the fields of cell perfusion applications and droplet generation, breaking free from the confines of traditional “lab on a chip” and “organ on a chip” technologies.

Microfluidics, renowned for its intricate control over small fluid volumes, overcomes conventional boundaries and finds applications across a range of fields.

- In cosmetics, microfluidics takes center stage, enabling precise crafting of emulsions and formulations and revolutionizing product development through increased efficiency and accuracy.

- In pharmaceuticals, especially in drug discovery, microfluidics accelerates experimentation, providing a sophisticated and resource-efficient approach.

- The healthcare sector benefits significantly from microfluidics, where the technology contributes to personalized medicine and diagnosis. Its precision in manipulating small fluid quantities opens the door to novel diagnostic approaches and tailored medical interventions.

- In chemistry, microfluidics has emerged as a tool for flow synthesis and stoichiometry, optimizing chemical processes.

- Biologists leverage microfluidics for cell culture and 3D printing, creating environments that closely mimic physiological conditions.

- Droplet generation applications further extend its versatility, with microfluidics emerging as a pivotal tool for creating and manipulating droplets with high precision.

- In energy applications, microfluidics plays a crucial role in Enhanced Oil Recovery (EOR) models and plasma confinement studies, showcasing its adaptability across different scientific disciplines.

- In industrial applications, microfluidics provides a platform for enhanced efficiency, precision, and cost-effectiveness.

Draw on microfluidic technology for your industrial application

- High-Throughput Screening: Microfluidic devices excel in conducting rapid and parallelized experiments, making them ideal for high-throughput screening in industries like pharmaceuticals and biotechnology. This enables quick testing of multiple conditions, reducing time and resource requirements.

- Process Miniaturization: Microfluidic systems allow for miniaturization of processes, leading to reduced sample and reagent consumption. This not only cuts costs, but also facilitates handling of scarce or expensive materials.

- Point-of-Care Diagnostics: Microfluidics plays a crucial role in developing portable and rapid diagnostic tools for on-site testing. These devices can be utilized in industrial settings for real-time monitoring, ensuring quality control and minimizing downtime.

- Customized Manufacturing: Microfluidics allows for the creation of tailored microenvironments to facilitate customized manufacturing processes. This is particularly beneficial in applications where specific conditions are required for optimal product development.

Custom box: Engineering solutions

- Automation and Integration: Microfluidic components can be easily integrated into automated systems, streamlining processes and reducing the need for manual intervention. This enhances overall workflow efficiency in industrial applications.

By leveraging the capabilities of microfluidics in these ways, industries can enhance their processes, reduce costs, and improve overall productivity.

The development of microfluidics has just begun!

Conclusion

Microfluidics offers revolutionary new capabilities. It is still quite a new technology, and there is a lot of work to be done so that it can solve problems for users who are not experts in fluid physics, such as clinicians, cell biologists, and public health officials.

Microfluidic applications and products are already present in the marketplace, especially in nanomedicine, allowing for more precise analysis of molecules like DNA and proteins, bacteria, or analysis at the scale of a single cell. The continuing development of high-throughput screening and organ-on-chip technology will lead to faster and better drug development. With the development of lab-on-a-chip and microTAS and the possibility of combining microfluidics with automation, new diagnostic products will be cheaper and faster, bringing benefits to developing countries.

Expertises & Resources

-

Microfluidics Article Reviews Pressure-driven flow controllers vs. Syringe pumps: A flow precision evaluation for optical blood imaging. Read more

-

Microfluidics White Papers Double emulsion for the generation of microcapsules – a Review Read more

-

Microfluidics White Papers A review of Organ on Chip Technology – A White Paper Read more

-

Expert Reviews: Basics of Microfluidics How to choose a microfluidic chip Read more

-

Microfluidics White Papers An exploration of Microfluidic technology and fluid handling Read more

-

Expert Reviews: Basics of Microfluidics Mastering Microfluidic Chips: An In-Depth Definition Read more

References:

- Fluigent, White paper: An exploration of microfluidics and fluid handling, 2020, https://www.fluigent.com/resources-support/expertise/white-papers/

- Bahnemann, J.; Grünberge, A. Microfluidics in Biotechnology: Overview and Status Quo. Advances in Biochemical Engineering/Biotechnology book series, 2022, ABE,volume 179.

- Agresti, J. J.; Antipov, E.; Abate, A. R.; Ahn, K.; Rowat, A. C.; Baret, J.-C.; Marquez, M.; Klibanov, A. M.; Griffiths, A. D.; Weitz, D. A. Ultrahigh-Throughput Screening in Drop-Based Microfluidics for Directed Evolution. Proc. Natl. Acad. Sci. U.S.A. 2010, 107 (9), 4004–4009.