Microfluidic volume definitions

Most of the time, it is useful to know the total volume of one’s fluidic circuit. Volumes in microfluidics can be different from other areas. The chip has its own volume, tubing has an internal volume. Fittings like unions, adapters or tees can have an enclosed volume that will contribute to the total volume of a system.

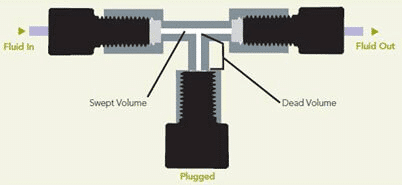

This is referred to in specification sheets as “internal volume”. The internal volume is the sum of two different volumes: the “swept volume” and the “dead volume”.

Introduction to microfluidics

The main goal of microfluidics is to miniaturize all the components of the fluidic platform as much as possible, which means working with very small amounts of liquid, ranging from 1 picoliter to 100 microliters. A certain amount of liquid is lost as it flows through the entire fluidic path towards the chip, and this quantity depends on the internal volume of the system. The challenge with microvolumes is to design chips and components with the smallest internal volume possible in order to minimize liquid losses.

Microfluidic swept volume

The swept volume is the portion of the internal volume that is directly in the flow pathway: fluids are bound to flow through this volume when flowing through the fitting. It is generally best to keep this swept volume as small as possible to help minimize the amount of sample or reagent required for your experiments, which can ultimately save you time and costs. Furthermore, the swept volume also affects the fluid dynamics of the system, for example by increasing the flow resistance, influencing how the fluid flows through the fitting and how the fluids mix.

To ensure optimal performance, it is important to consider the swept volume when choosing fittings and designing your microfluidic system. Fluigent offers a variety of fittings to meet the needs of different applications.

Microfluidic dead volume

Another type of volume in a microfluidic setup is the dead volume. This is the portion of the internal volume that is out of the flow path. This means that any liquid that flows into this area or any molecules that diffuse there may not be recovered, or may only be recovered later on. As such, the dead volume can be thought of as a kind of “buffer tank”. Of course, all manufacturers of microfluidic parts try to minimize the dead volumes in their fluidic products. Dead volume can become an issue when several samples need to flow through the same path but mustn’t contaminate one another.

Microfluidic internal volume

The dead volume and the internal volume have to be differentiated, as it is sometimes the case. The internal volume is the sum of the swept and the dead volumes.is critical for many microfluidic applications.

Indeed, when an experiment needs to simulate biological or mathematical flow profiles, a highly responsive pump is necessary to generate sine waves, ramps, If the connection with the tubing is not optimized, an additional internal volume can be created. To help the liquid to flow directly and completely into the chip from the tubing, ensure that all tubing is fully seated and tightened at all times. A good practice is also to try to match the tubing ID as closely as possible to the diameters of the inlet/outlet ports of one’s chips.

Reducing internal volumes in microfluidic experiments

At Fluigent, we understand the importance of minimizing the volumes used in microfluidic platforms. One way to achieve this is through the use of microfluidic chips and elements with a low “dead volume,” which is the portion of the internal volume that is not directly in the flow pathway and can cause liquid loss. Another approach is to optimize the flow pathways within the chip to minimize the “swept volume,” which is the portion of the internal volume that is directly in the flow pathway. This can be achieved using advanced microfluidic technologies such as the FASTAB™ system, which allows for precise control of fluid flow and mixing. Implementing efficient liquid handling solutions can also help to reduce volumes in microfluidics. At Fluigent, we are constantly researching and developing new ways to minimize problematic microvolume experiments and improve the overall performance of our microfluidic platform.