Valve actuation timing

M-SWITCH™ Microfluidic bidirectional valve

[ESSMSW003]11-port/10-position microfluidic valve

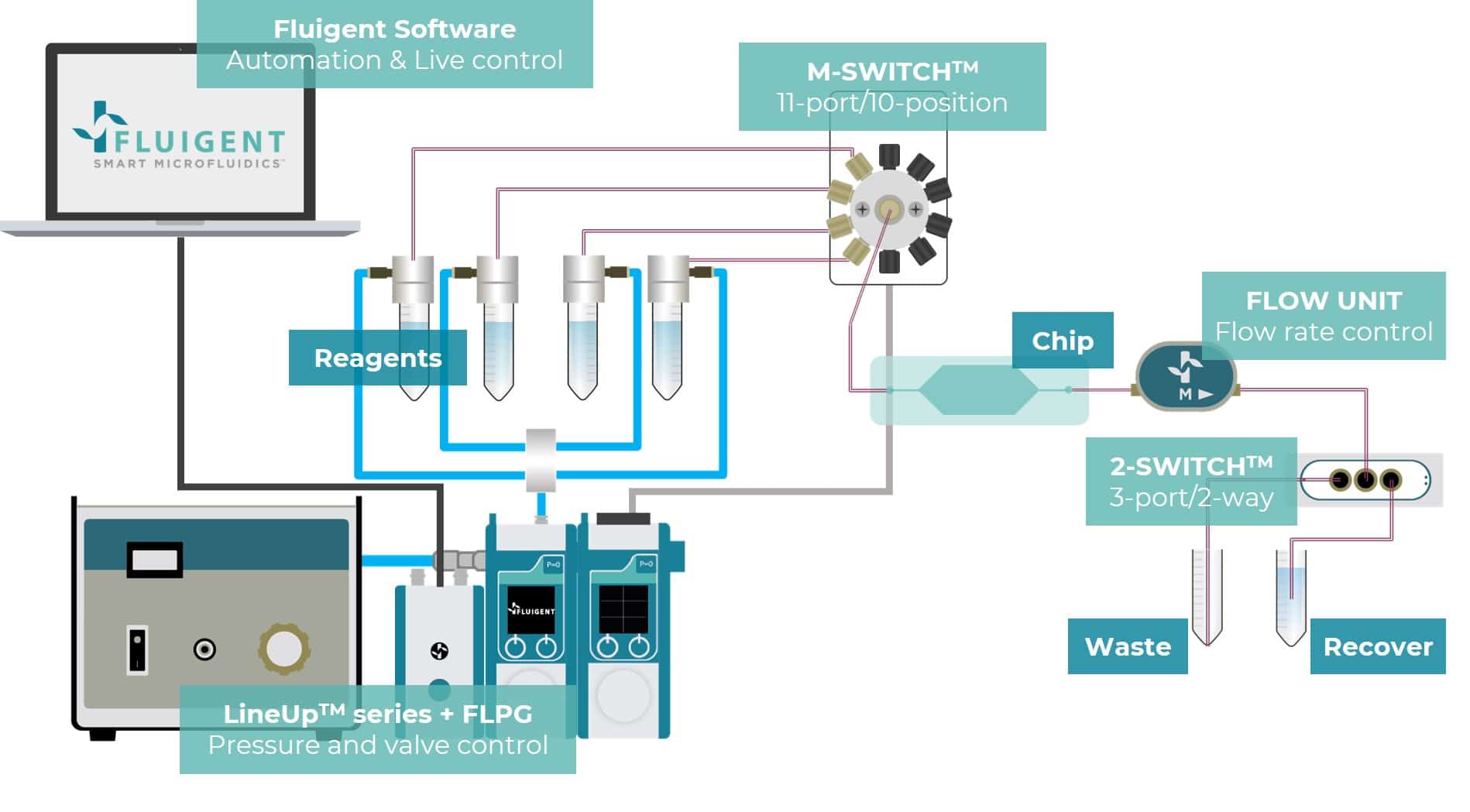

The M-SWITCH™ is an 11-port/10-position microfluidic bidirectional valve for injection or selection of up to 10 different fluids or chips. The flow is bidirectional in the valve. The device can be used as a distributor or as a selector for either multiplexing or demultiplexing purposes.

- Automation

- Compact

Uses minimum bench space

- Quick

Actuation & Response time

- Accurate

Low internal volume

Features of the M-Switch microfluidic dual flow control valve

Any of the peripheral ports (numbered from 1 to 10) can be connected to the central channel, and the fluidic path created is bidirectional. The M-SWITCH™ is actuated by a motor that drives a rotor. It can also be used with a manifold to use a single pressure pump to deliver multiple liquids and simplify setups.

Generating and collecting samples

Different concentrations of the molecule of interest can be injected into a chip generating water-in-oil droplets. The droplets can then be sorted at the outlet of the chip using the M-SWITCH™ microfluidic bidirectional valve according to their analyte concentrations. Each step can be automated using OxyGEN software.

How does the 11-port/10-position system work?

Any of the peripheral ports (numbered from 1 to 10) can be connected to the central channel, and the fluidic path created is bidirectional. The M-SWITCH™ is actuated by a motor that drives a rotor. It can also be used with a manifold to use a single pressure pump to deliver multiple liquids and simplify setups.

The M-Switch, an automated microfluidic valve

The microfluidic bidirectional valve can be controlled by OxyGEN software for long-term experiments. Create a time-based protocol to set actuation timing.

Smart control and automation of your fluidic path

Discover Fluigent microfluidic valves, a set of compact instruments that lets you complexify and easily handle the fluidic path of your system. Once integrated into the setup, the valves can be controlled in real time, even without a PC.

Related applications

Smart control and automation of your fluidic path

Discover Fluigent microfluidic valves-: a set of compact instruments allowing users to complexify and easily handle the fluidic path of their system. Once integrated in the set-up, the valves can be controlled in real-time and even without the requirement of a PC.

What are the benefits of this microfluidic switching valve?

- Fast switching time: 400ms, making it compatible with our ultra-fast flow controllers

- Ultra-low internal volume: 3.5µL

- Versatility and ease of use

- Multiplexing: up to 10 different fluids

Example uses of the M-Switch

Automatic switching between multiple solutions while maintaining a constant flow rate

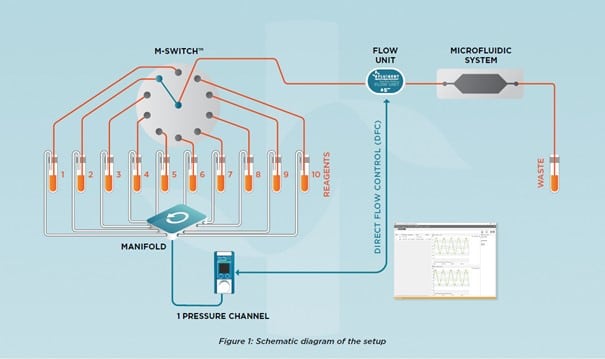

Many microfluidic applications require switching between multiple solutions (such as samples or buffers) while maintaining a constant flow rate during the associated experiment. In this application, one Flow EZ™ pressure channel is connected via a manifold to ten separate vials containing different aqueous solutions. Using the M-Switch™ and Oxygen software allows for selection of a specific solution to be directed to a microfluidic device. This represents an economical way to change between fluids, as it requires only a single pressure channel and one flow sensor.

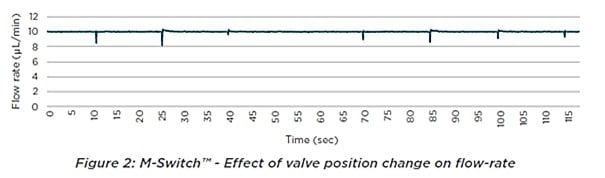

The microfluidic switching valve is first set to position 1, and a constant flow rate of 10µL/min is applied. A flow unit M coupled with a flowboard allows real-time monitoring of the flow rate for constant adjustment of the pressure. Then the M-switch position is changed to the next sequential position at several time points, and the measured flow-rate is recorded.

The data for each switching interval was analyzed to determine the settling time for each change of position. Although it is possible to visually identify the switching step when reading the raw Oxygen data, in all cases normal flow was re-established within 100 ms or less. It is important to note that the flow rate is always positive during the switching steps, eliminating the possibility of cross-contamination between the various solutions.

For more information, read our application note on this use of the microfluidic bidirectional valve.

“We have been using Fluigent’s M-SWITCH, amongst other accessories, including Flow EZ system flow controllers, for the past 5 years. We are pleased with its performance, especially the programmability and automation of fluid flow that relieves the user of the need to be present next to experiments that run for several hours. We found the software interface simple to use and could count on the team’s assistance for friendly recommendations and support.”

Sivashankar Krishnamoorthy – Luxembourg Institute of Science and Technology (LIST)

Specifications

PERFORMANCE

| Switching time | 400 ms (180°) |

| Maximum pressure | Up to 7 bar (102 psi) |

HARDWARE SPECIFICATIONS

| Internal diameter | 0.5 mm |

| Internal volume | 3.5 µL |

| Dead volume | None |

| Carryover volume | 1.7 µL |

| Tube port fittings | Standard 1/4 – 28 UNF, flat-bottom |

| Wetted materials | PCTFE, UHMW-PE |

WEIGHT AND DIMENSIONS

| Dimensions | 60 x 110 x 110 mm (2.36 x 4.33 x 4.33 in) |

| Weight | 746 g (1.64 lbs) |

OPERATING CONDITIONS

| Operating temperature | 15-40°C (59-104°F) |

| Operating humidity | 20-80%, non condensing |

ELECTRONICAL SPECIFICATIONS

| Power consumption | 2 A (peak) |

| Port communication | RJ45 |

CHEMICAL COMPATIBILITY

| Gas compatibility | Dry, oil-free gas, air, any non corrosive or non explosive gas |

| Liquid compatibility | Aqueous solvent, oil, organic solent, biological sample |

OxyGEN

| Control in real-time, protocol automation, data record and export |

| ver. 2.2.0.0 or more recent |

Software Development Kit

| Custom software application |

| ver. 22.2.0.0 or more recent |