Insights from Fluigent's Innovator in Microfluidics

Product Manager Interview

Can you introduce yourself and tell us about your role at Fluigent?

After earning an engineering degree in Switzerland and spending two years working in microfluidics, specifically droplet microfluidics and single-cell analysis, I joined Fluigent as an application engineer in 2019. In 2022, I became the Product Manager at Fluigent. My focus is on delivering successful products to customers through precise product marketing and strategic product planning.

You currently offer a wide variety of smart microfluidic instruments for research. Can you tell us more about your products?

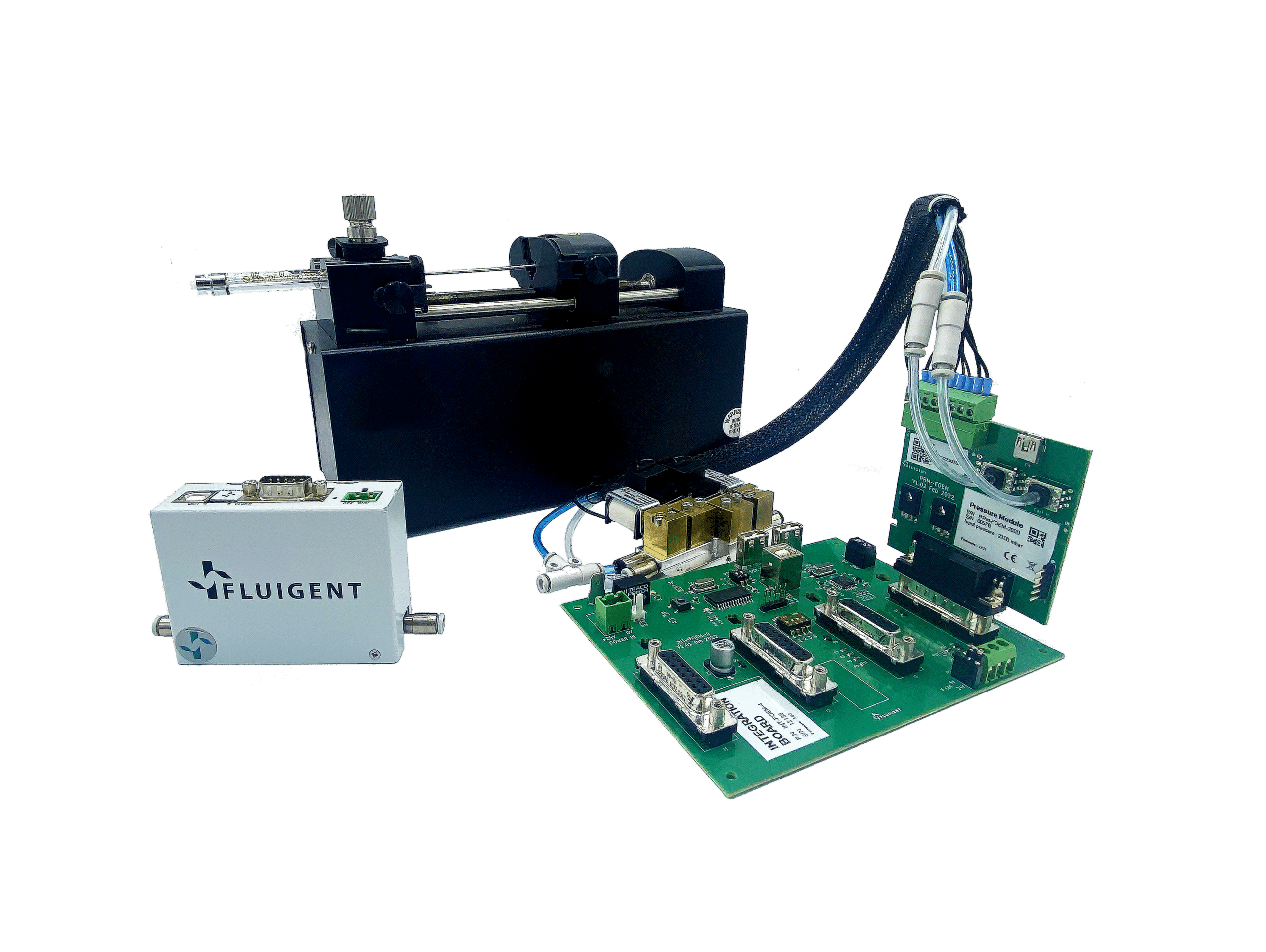

We offer a comprehensive range of solutions for microfluidics, including pressure and vacuum control, flow rate control, microfluidic valve automation, and software control. Our flagship product range, LineUp™, is dedicated to microfluidic flow management, allowing users to select and combine the necessary modules to meet their specific needs.

The range of LineUp™ products is amongst Fluigent’s best-sellers. Can you tell us more about how you developed this solution?

A few years ago, we identified several challenges that microfluidic researchers faced when using existing flow controllers:

- Syringe pumps or peristaltic pumps: Although easy to use, these pumps often exhibit performance limitations in flow rate accuracy, stability, and response time, ultimately affecting the results of microfluidic experiments.

- Former pressure controllers: While offering improved flow performance over syringe pumps, these controllers were often complex, bulky, and lacked the modularity found in syringe or peristaltic pumps.

Based on these observations, we aimed to provide an optimal solution for microfluidic users by addressing the limitations of existing flow rate controllers. This led to the development of the LineUp™ product range, which we believe is the best solution for flow control available today.

You claim the LineUp™ product range is the best solution in microfluidics. Can you explain why?

Our products excel in microfluidics due to the following benefits:

- The best performance on the market: Fluid management needs can vary significantly between microfluidic experiments, requiring long-term flow rate injection with excellent stability, fast response time, high shear stresses and pressures, as well as multiplexing capabilities. We developed the Flow EZ with the goal of providing optimal performance for all types of microfluidic applications. Key innovations include:

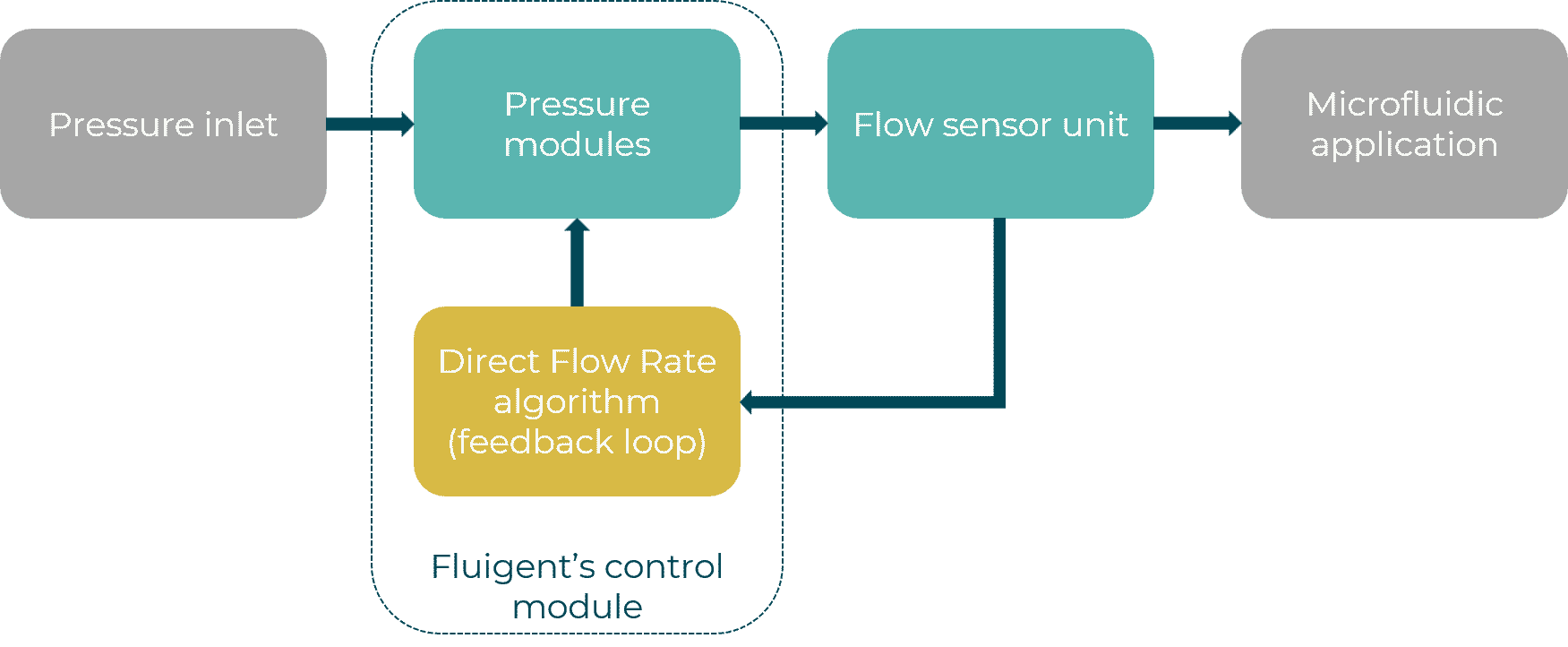

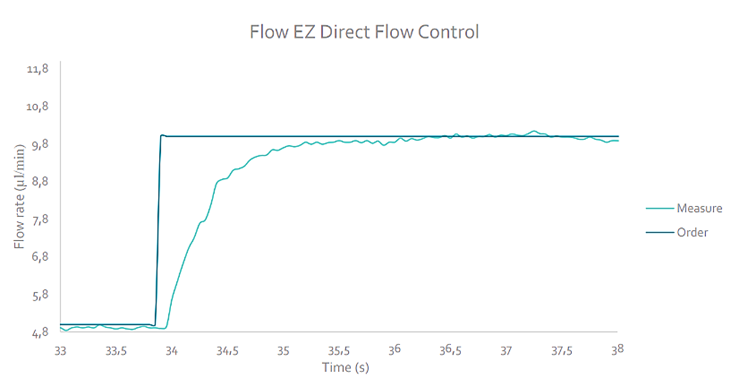

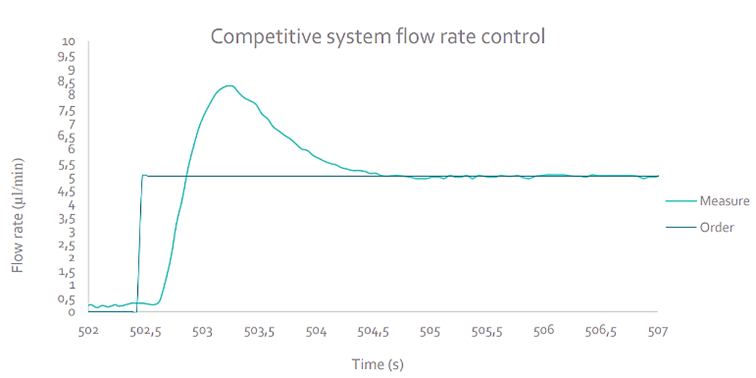

- Self-learning flow control algorithm (Fluigent DFC): This algorithm addresses issues in microfluidic flow control such as calibration, multi-channel interaction, and resistance changes during experiments. It ensures optimal regulation (no overshoot, high accuracy, fast response time) from the start of the experiment, unlike competitor solutions.

- Advanced technologies in our pressure controllers: Our R&D team selected top-tier pressure sensors and solenoid valves, combined with our expertise, to deliver superior performance: <1 second response time, 0.1% precision, 5% accuracy in flow rate control, and a pressure range of -800 mbar to 7000 mbar. These specifications ensure accurate and reproducible microfluidic experiments.

- Modular: We developed five distinct modules, each with a specific function:

- Flow EZ™ or Push-Pull modules: Precisely regulate and control pressure and vacuum.

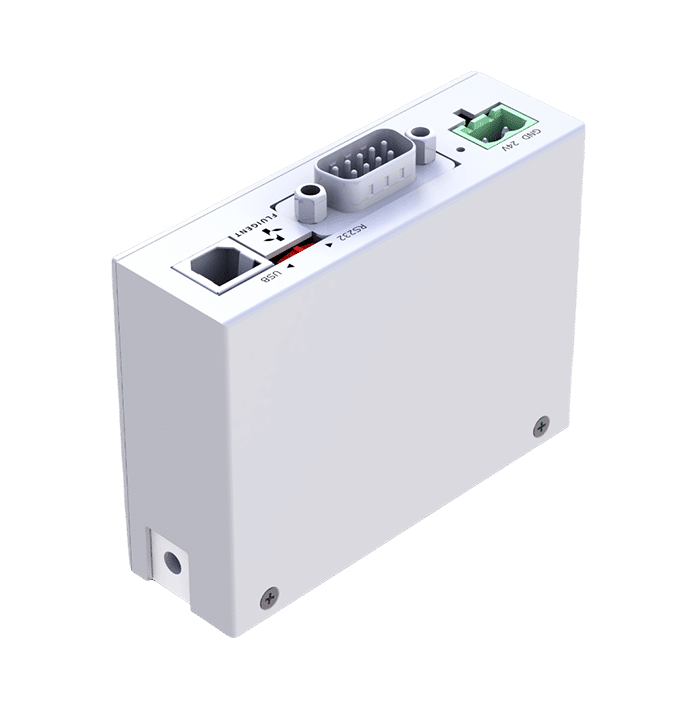

- LINK module: Provides communication to a computer for using our OxyGEN software.

- Adapt: Connects Flow EZ™ modules with different pressure ranges without additional pressure sources.

- P-SWITCH: Multiplies the outlets of the system.

- SWITCH EZ: Controls microfluidic valves.

Each microfluidic flow regulator is an independent pressure channel. Users can add or remove modules as needed, allowing up to eight flow control modules to be combined. This design minimizes bench space usage, enables setup adaptation for different experiments, and facilitates sharing the device across multiple laboratory rooms. We recently enhanced customer experience by improving the mechanical connection between the LINK and other modules using magnets on the side panels. Check out our latest video!

3. Ease of use through local control: Our LineUp™ products can be used without a PC. Connect the controllers to the power and pressure supply, and they are ready to use thanks to local knobs and dials. This allows for quick setup and experimentation, enabling users to focus on their experiments rather than the PC. For more complex experiments, the complete flow rate protocol can also be automated using our dedicated OxyGEN software.

On your website, you state that your ‘microfluidic technologies allow you to focus on science, not on the setup’. Why is this so important for innovation?

Scientists and industrials need to focus on their highest-value activities: discoveries, new applications, and new devices. Over the years, we have encountered scientists who spent considerable time developing and assembling their flow controllers. For example, Ph.D. students could spend over six months developing a flow controller before starting their research experiments, only to end up with average equipment.

Our value proposition is to offer ready-to-use, high-end products so users can focus on what matters. By enabling scientists to concentrate on their research, we believe we accelerate innovation and discoveries. Facilitating the development of new tools for diagnostics, therapeutics, and devices helps accelerate their time to market and their impact on society.

Related Product

Related Expertises

- Microfluidics Article Reviews

Pressure-driven flow controllers vs. Syringe pumps: A flow precision evaluation for optical blood imaging.

Read more - Expert Reviews: Basics of Microfluidics

Flow control for droplet generation using syringe pumps and pressure-based flow controllers

Read more - Expert Reviews: Basics of Microfluidics

Microfluidic Flow Control: Comparison between peristaltic, syringe and pressure pumps for microfluidic applications

Read more - Microfluidic Application Notes

Peristaltic Pump vs Pressure-Based Microfluidic Flow Control for Organ on Chip applications

Read more

5 reasons to choose OEM pressure controllers over OEM syringe pumps for microfluidic applications

Read more- Microfluidics Article Reviews

A mRNA encapsulation platform integrating Fluigent’s FlowEZ

Read more - Microfluidics case studies

A multiplex microfluidic circuit for blood vessel-on-a-chip perfusion using Fluigent’s FlowEZ

Read more