Case study: Single crystal formation in core-shell microcapsules.

Overview:

This webinar introduces the latest advances in core-shell microcapsule technology. Discover how microcapsules are used as a versatile tool in drug delivery, encapsulation, crystallization, compound characterization, and more.

Explore the challenges of traditional microencapsulation methods and the transformative potential of microfluidic technology in producing precise, uniform microcapsules. Gain insights into the advantages of UV light crosslinking for rapid and solvent-free capsule production (Methacrylate-based resins, PEGDA, PEGDMA).

In the case study discussion of the program, a particular emphasis will be placed on the use of microcapsules for the screening of crystallization conditions.

Learn how to generate hundreds of identical UV-crosslinked microcapsules per second, produced by Secoya Technologies’ RayDrop and its all-in-one platform.

Agenda:

✅ Introduction to microfluidic-based core-shell microcapsules: Technology, advantages, and drawbacks compared to traditional methods.

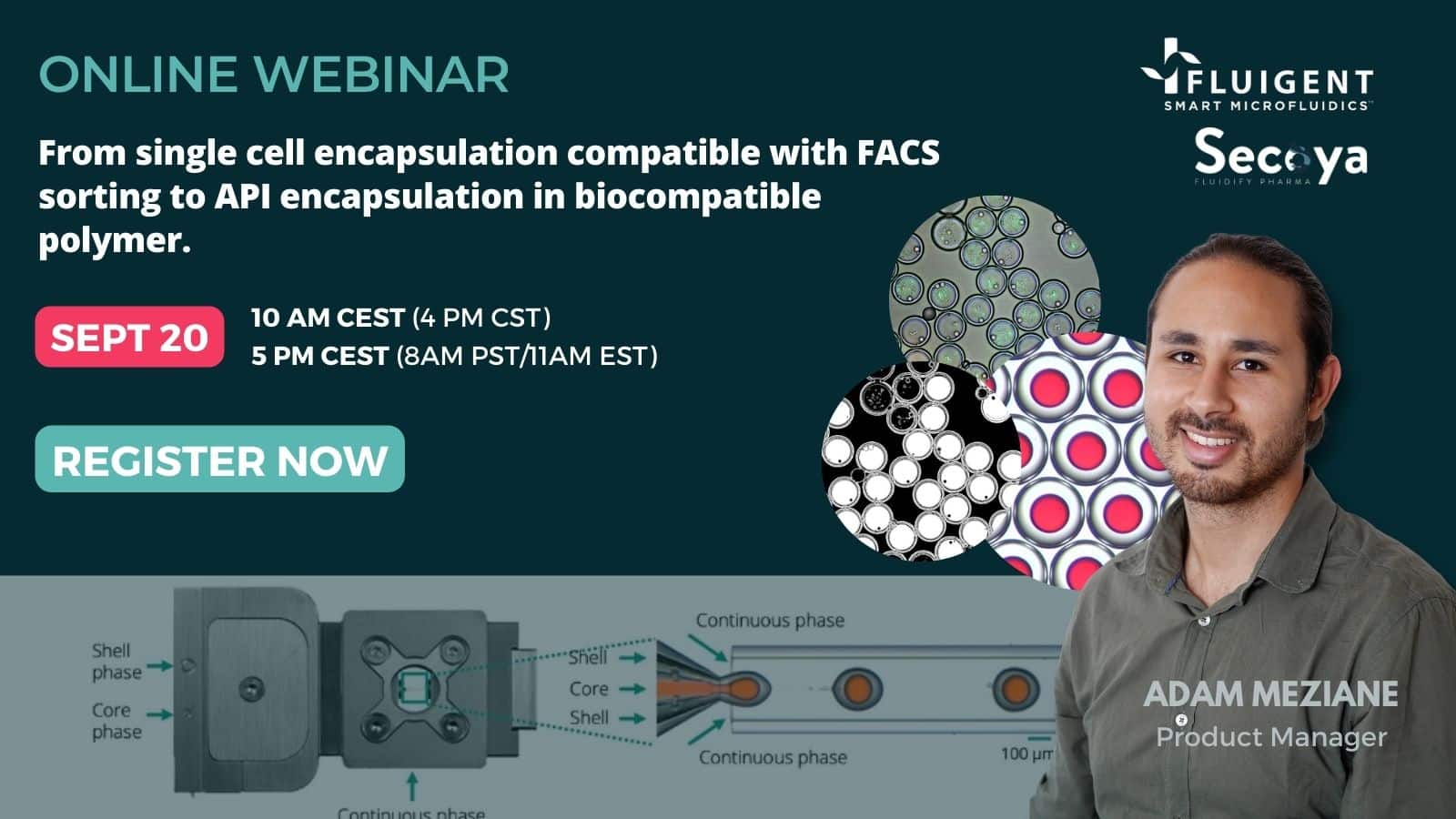

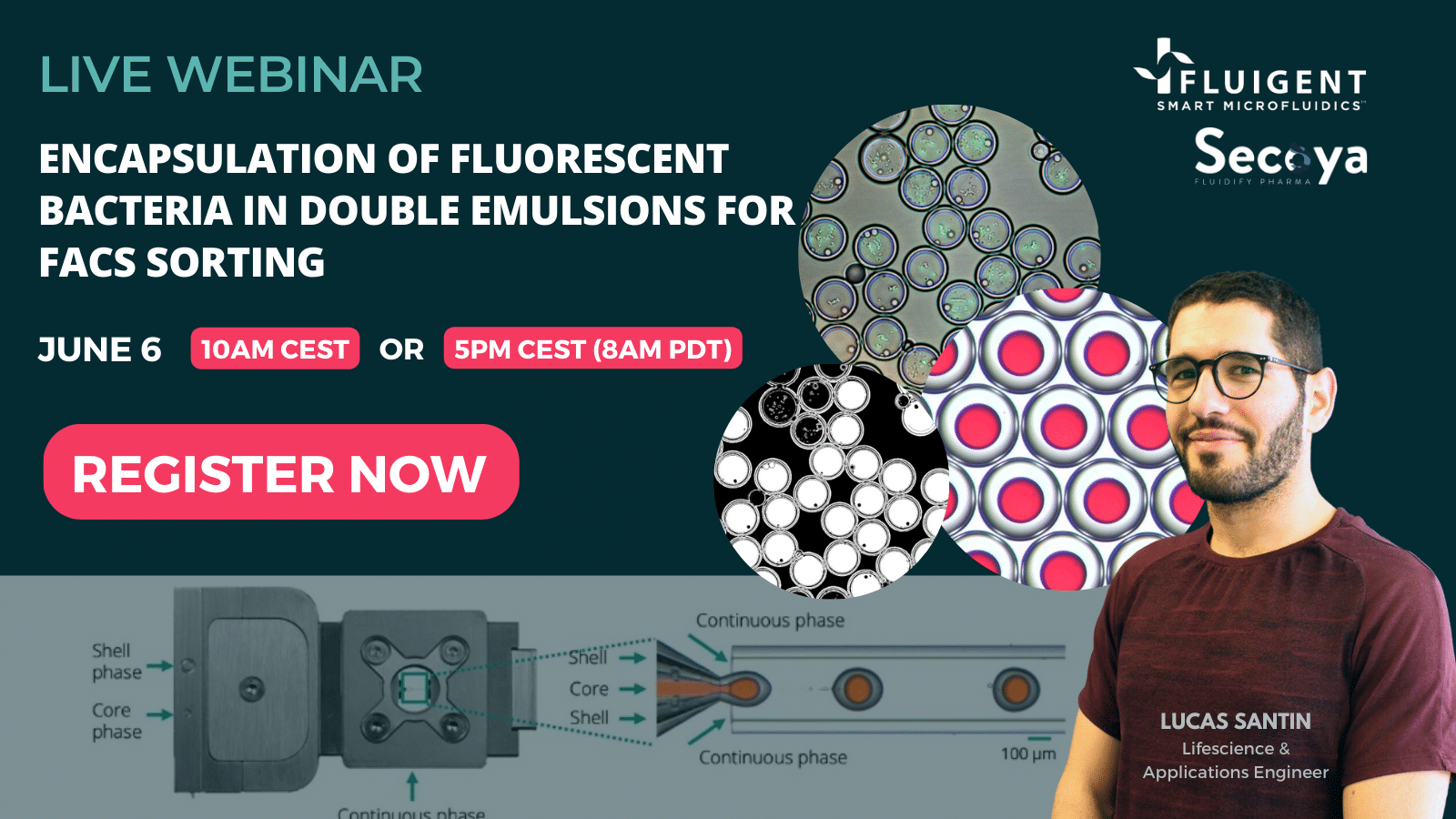

✅ Presentation of the double emulsion device (RayDrop) and platform: How to simplify microcapsule complexity production with high precision, low investigated volumes, and an all-in-one platform (microfluidics, droplets, optics, UV-crosslinking).

✅ Case Study in crystallization: Single crystal formation in core-shell microcapsule applications.

✅ Interactive Q&A Session

Speakers:

Joseph Farah : Microfluidic Application Engineer·

Marie Mettler : R&D Engineer – Secoya Technologies

Adrien Dewandre : Technology Lead – Emulsification & Droplet generation – Secoya Technologies

UV-crosslinked microcapsule production platform

The UV-crosslinked microcapsule production platform, developed and manufactured by Secoya Technologies, is a complete system for the continuous creation of core-shell microcapsules with control over size and structure.

Based on a droplet microfluidic approach, Secoya Technologies’ RayDrop device produces monodisperse double emulsions which lead to monodispersed microcapsules, while Fluigent’s Flow controllers and Flow Units guarantee high flow stability and responsiveness. Microfluidic, mechanical, optical, and UV modules are all included in the platform for easy, fast, and practical usage.