Are you working in academia or industry in the field of cosmetic, food, pharma, or chemical process? If you are looking for solutions and methods to improve and gain performance in generating the right double-emulsion for your needs, this online workshop may be of benefit to you. Until now, generating double emulsions has been a challenge as existing technologies suffer from various limitations (low reproducibility, …).

Overview

Double emulsion could be defined as droplet encapsulated within a larger droplet of different immiscible phases. Making double emulsion is a widespread method for many applications. This method shows advantages and potential in many applications such as in food for flavor release or cosmetics for fragrance and flavor release (toothpaste, perfume…), in pharmaceutics for drug delivery ( Protection of API in microcapsules for control drug release) and other.

Whereas double emulsion is a promising method for many applications, technologies to make double emulsion such as batch methods are all suffering from various limitations (low reproducibility, big size distribution…)

Microfluidics which consist of precisely control fluids at micrometric scale is a promising technology for making double emulsion. However, this technology requires microfluidic chips and devices made of specific materials ( mostly hydrophobic such as PDMS or hydrophilic such as Glass ). Physical properties of the materials remains a big limitation for double emulsion because allow generating simple emulsion (w/o, o/w) but it’s become almost impossible to reach double emulsion (w/o/w or o/w/o) without using a chemical coating on the chip which has a lifetime and is not robust enough for long term production.

During this webinar, we are going to present the only device available on the market which allows to easily produce double emulsion with any kind of solution without chemical surface treatments needed.

What you will learn

Discover a new method for double emulsion production

Speakers

Why explore double emulsion microfluidics?

Double emulsion microfluidics—defined as a process of encapsulating droplets within other droplets—allows for a higher level containment, encapsulation, compartmentalization, and controlled delivery of biological samples or templates. This technique proves useful in drug delivery, single cell studies, material development, or even formulating food and cosmetics. With precise control over release dynamics, core size, and shell thickness, double emulsions serve as an adaptive basis for creating complex engineered systems designed to specific requirements.

Curious to know more? Discover key reviews covering into the potential and techniques behind double emulsion microfluidics

- Expert Reviews: Basics of Microfluidics

10 Tips for Reliable Droplet Generation

Explore more - Microfluidics White Papers

Double emulsion for the generation of microcapsules – a Review

Explore more - Microfluidics White Papers

Droplet-based Microfluidics – A Complete Guide

Explore more - Microfluidic Application Notes

A quick and efficient double encapsulation method for FACS-based droplet sorting

Explore more

Microfluidic Complex Emulsion Production Platform

This complex emulsion production platform, developed by Secoya, and using our flow control equipment, is a fast and easy screening system to perform emulsification processes such as single emulsions and double emulsions. Save time with an integrated, organized, ready-to-use platform and get monodispersed complex emulsions rapidly.

Raydrop Double Emulsion Device

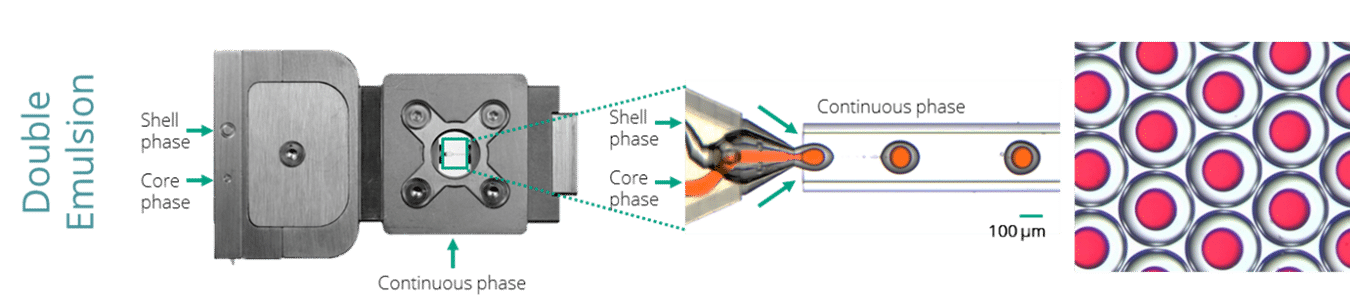

The RayDrop is a microfluidic double emulsion device composed of three main, fully removable parts: two inserts on each side,a center section containing a nozzle, and an outlet capillary.

The RayDrop specific design allows for multiple liquid type emulsification within the same device with no coating needed. The device can create both single and complex emulsions.

- Microfluidic Application Notes

Double Emulsion Generation

Read more Webinar – Robust technology for double emulsion production

Read moreWebinar – Polymerization of microfluidics-produced liquid crystal double emulsions for making wavelength and polarization-selective retroreflectors

Read moreWorkshop – Double emulsion production compatible with fluorescence-activated cell sorting (FACS) for cell sorting application

Read more