Life Science & Diagnostic OEMs struggle to perform liquid flow rate measurement while guaranteeing sterility in microfluidic applications. Using inline flow sensors can lead to contamination, calibration, and clogging issues.

With the growth of biological applications that make use of micro and millifluidics such as cell cytometry or purification for sample preparation, drug screening, organoids, or organs on chips, the need for a fully sterile, and disposable environment on the fluidic line is intensely growing.

Yet there was no solution for measuring the flow rate in a non-invasive manner, until today.

Summary:

00:47 ✅Importance of flow rate monitoring and control

05:34 ✅Main flow sensing technologies on the market & their challenges

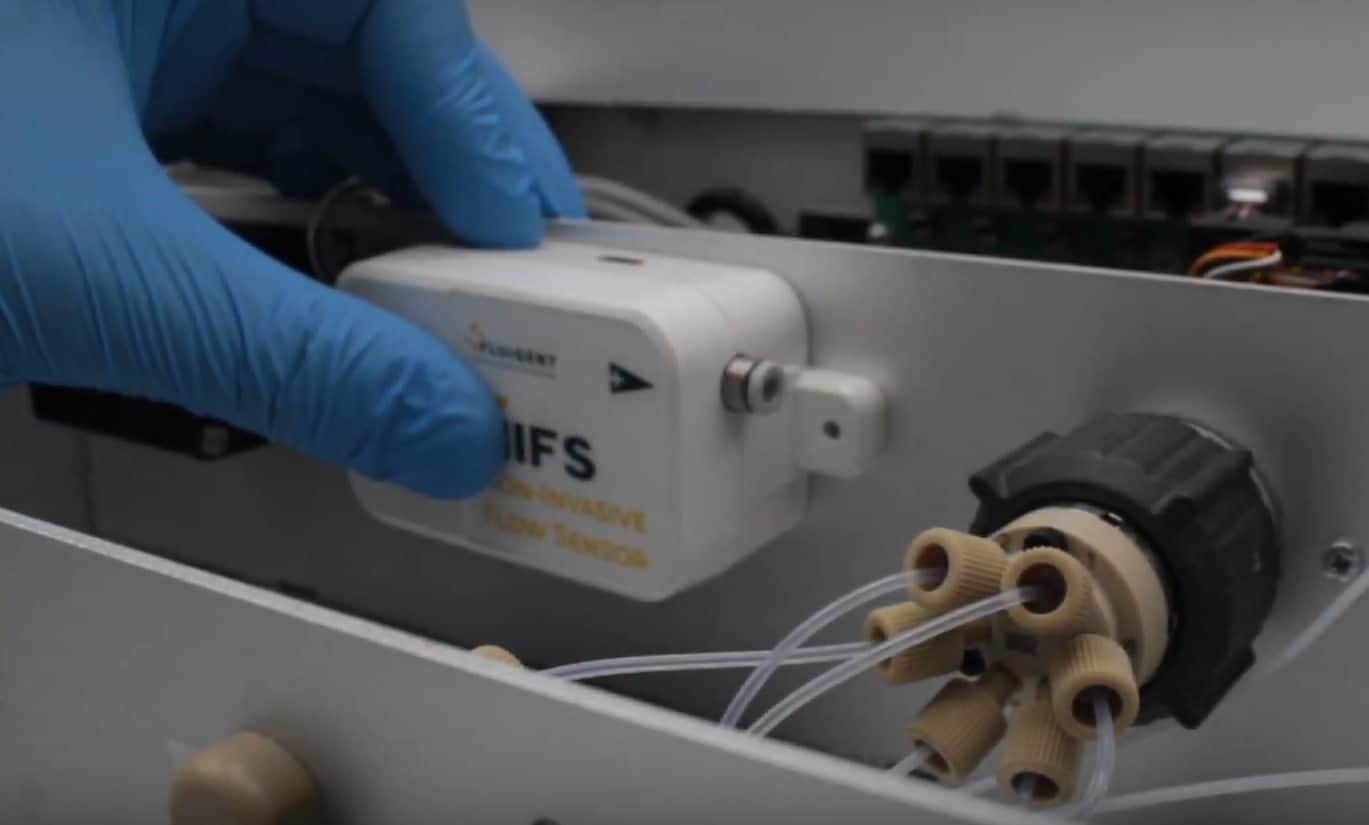

10:49 ✅New disruptive and unique product intro: Non-Invasive Flow Sensor (NIFS)

27:15 ✅Product video setup and first tests

36:25 ✅Q&A

More flow sensing expertises

Non-Intrusive Flow Sensing Technology

Read more- Expert Reviews: Basics of Microfluidics

Microfluidic Flow Sensing Technologies, A Review

Read more

Microfluidic OEM: automated liquid handling solutions

Fluigent industrial builds on our 15 years of pressure-based flow control expertise and proprietary technologies to bring versatile, cost-effective, and customizable microfluidic OEM products and systems to global users.

Microfluidic OEM

Read more- Expert Reviews: Basics of Microfluidics

Key reliability indicators for OEM components to ensure long-term performance of your flow control system

Read moreIn this short blog, we review the most important aspects to consider when selecting fluid handling OEM components.

F-OEM

Read moreModular OEM Microfluidic Flow Controller